Air-cooled shock absorber

A shock absorber and air-cooled technology, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problem of affecting the surface ventilation and heat dissipation of the shock absorber, affecting the service life of the shock absorber, and the water absorption of the water-absorbing parts limited problems, to achieve the effect of easy maintenance alone, improve heat transfer efficiency, and avoid carbonization or volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

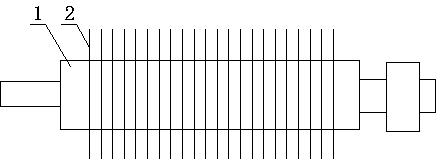

[0026] Such as figure 1 Shown: an air-cooled shock absorber, including a shock absorber body 1 and a number of heat sinks 2 arranged outside the body 1, the heat sink 2 is an annular fin structure, and is evenly arranged outside the body 1 .

Embodiment 2

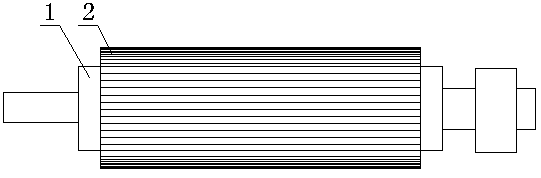

[0028] The difference between this embodiment and Embodiment 1 is that: the body 1 is provided with a heat dissipation cylinder 3, and the heat dissipation cylinder 3 is fixedly sleeved outside the body 1 through fixing parts 4 such as bolts, rivets or sealing rings, so that The cooling fins 2 are arranged on the cooling tube 3, and thermal conductive silicon grease is filled between the cooling tube 3 and the shock absorber body 1, and the cooling fins 2 are provided with reinforcing ribs connecting each cooling fin.

Embodiment 3

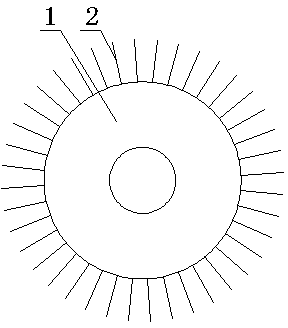

[0030] Such as figure 2 , image 3 Shown: an air-cooled shock absorber, including a shock absorber body 1 and a number of cooling fins 2 arranged outside the body 1, the cooling fins 2 are on the same plane as the central axis of the body 1, and The central axis is the central line and is distributed radially.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com