Horizontal colter vacuum drying and mixing machine

A technology of vacuum drying and mixer, applied in the direction of mixer, mixer with rotating stirring device, mixer accessories, etc., can solve the problems of mixing dead angle, achieve the effect of solving mixing dead angle, improving process and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

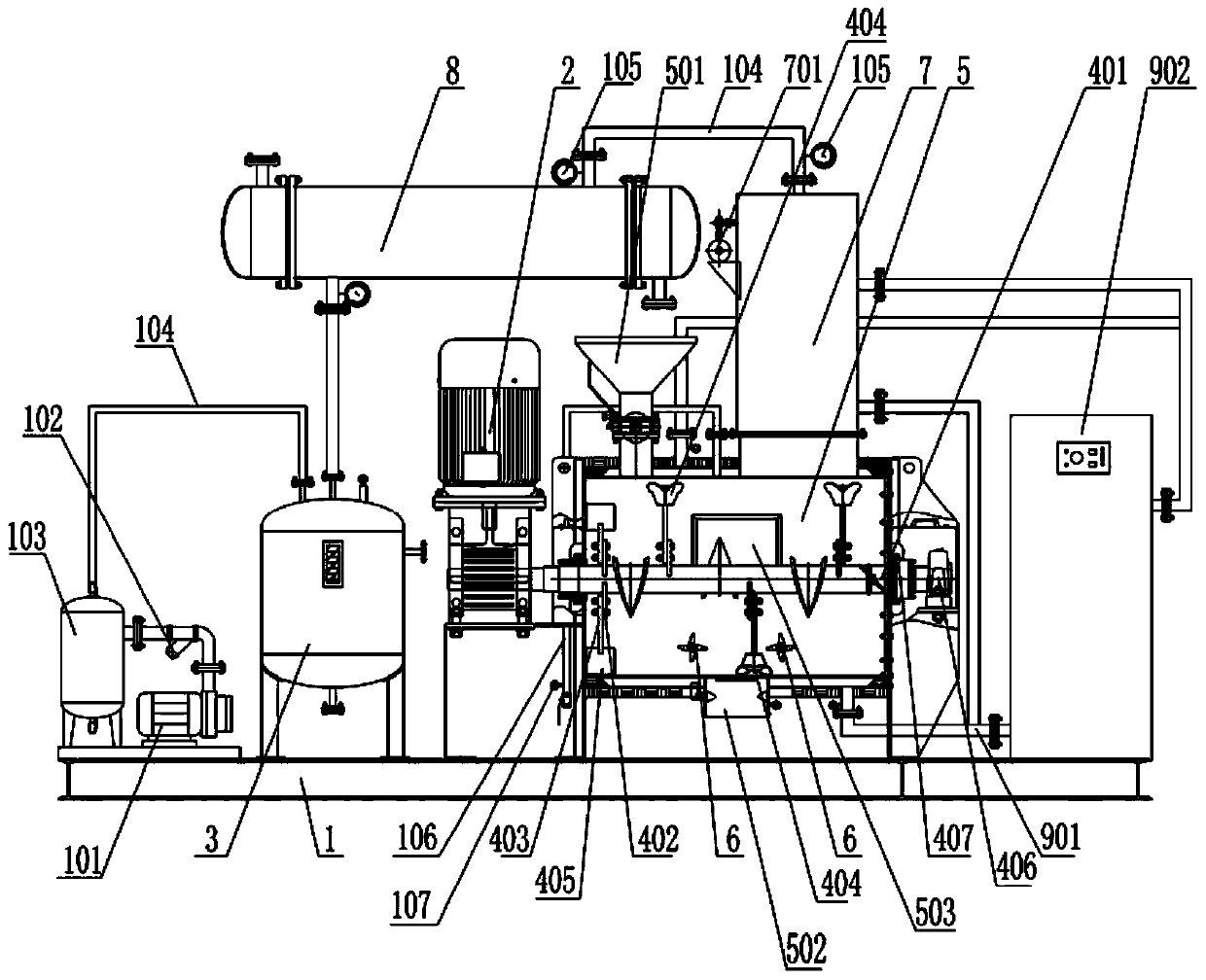

[0021] Such as figure 1 As shown, a horizontal coulter vacuum drying mixer includes a frame 1, a prime mover 2, a collection tank 3, a stirring shaft assembly 4, a cylinder body 5, a flying knife device 6, a dust collector 7, and a condenser 8 , heating system, vacuum system and electrical control system.

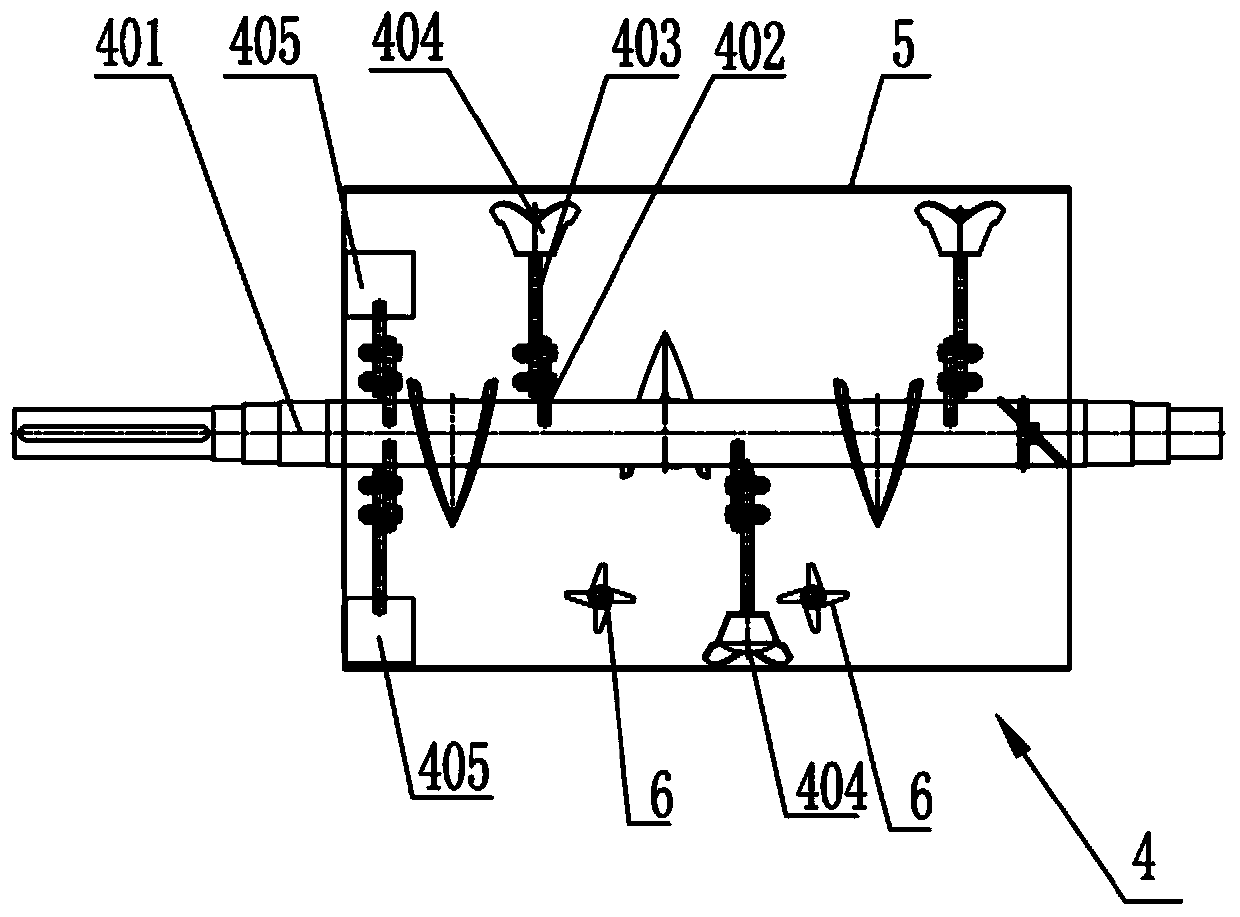

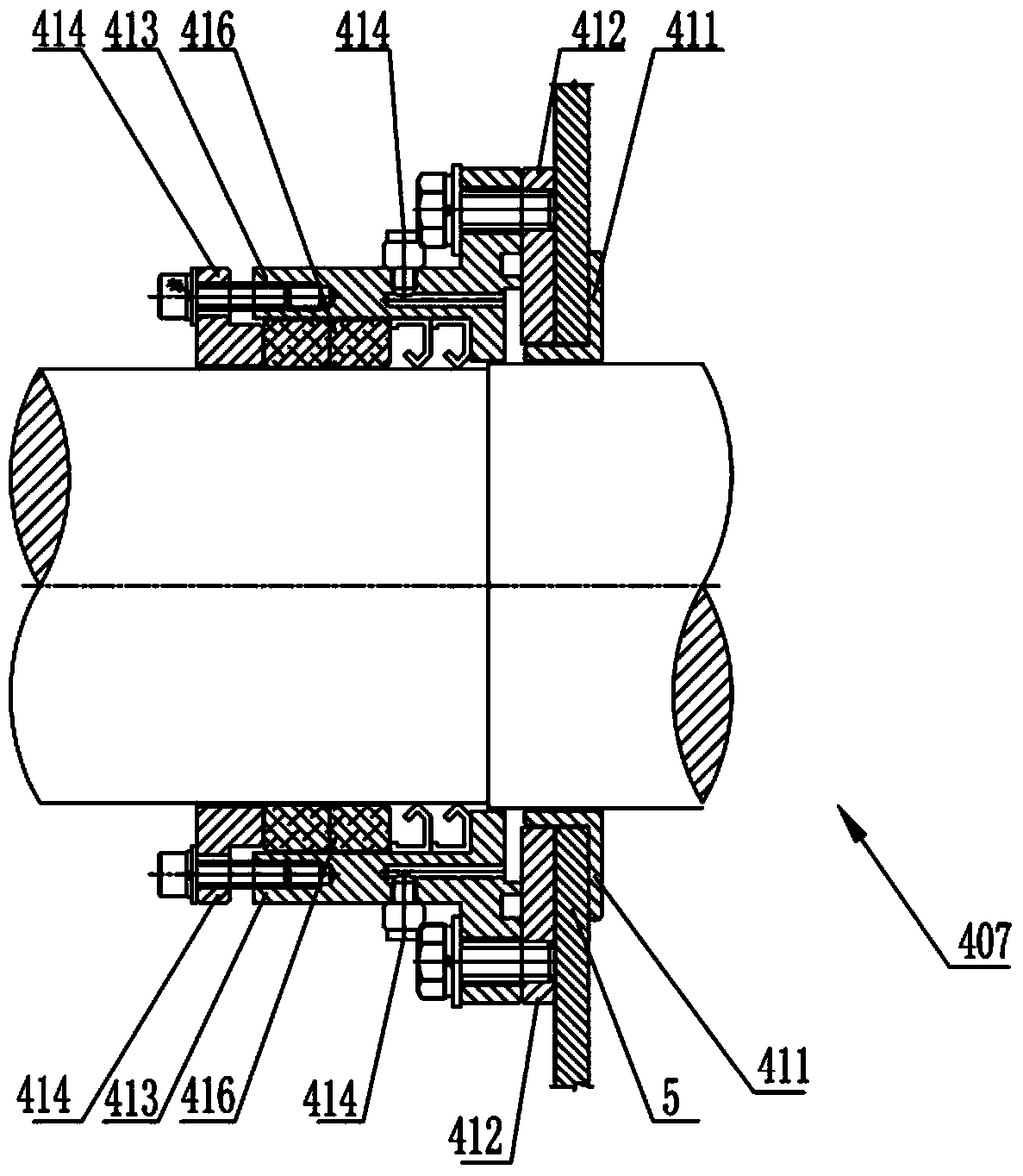

[0022] The stirring shaft assembly 4 is installed on both sides of the frame 1, including: a main shaft 401, a fixed stirring arm 402, a movable stirring arm 403, a coulter head 404, a scraper 405, a bearing seat 406 and a shaft end sealing device 407. The mixing shaft assembly 4 and the cylinder body 5 form a mixing chamber, one end of the main shaft 401 is connected with the prime mover 2, and the other end extends from one end of the cylinder body 5 to the other end, and the movable end of the main shaft 401 is fastened with bolts, etc. The parts are fixed and supported on the bearing seat 406, and cooperate with the reducer through the shaft end sealing device 407. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com