A self-produced hydrogen peroxide electrolysis water treatment device

A treatment device, a technology for electrolyzing water, applied in the directions of oxidized water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of reducing operating costs and eliminating the need for dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

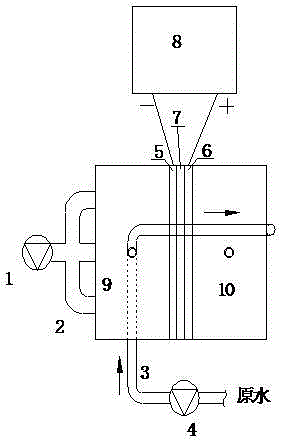

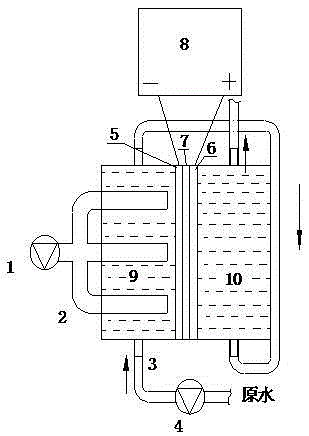

[0013] A self-produced hydrogen peroxide electrolyzed water treatment device, powered by a DC stabilized power supply, the core is an electrolytic cell, the electrolytic cell is composed of a catholyte chamber 9, an anolyte chamber 10 and a Nafion membrane 7, the catholyte chamber 9 and the anolyte chamber 10 is separated by the Nafion film 7, the cathode 5 and the anode 6 are close to the Nafion film 7 both sides, and at least three air pipes 2 are arranged facing the cathode 5 in the catholyte chamber 9, and the ends of the air pipes 2 are far from the cathode The surface of 5 is 0.5 cm, the other end of the air pipe 2 is connected to the air pump 1, the water flow pipe 3 enters from the bottom of the catholyte chamber 9, flows out through the top of the catholyte chamber 9, enters the bottom of the anolyte chamber 10, and finally flows out through the top of the anolyte chamber 10.

[0014] The cathode 5 adopts C / PTFE gas diffusion cathode, and the anode 6 adopts titanium me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com