Energy-saving environment-friendly glaze fetching device

An energy-saving, environmentally friendly, bucket technology, applied in the field of daily ceramics, can solve the problems of easy precipitation and stratification of glaze water, cumbersome cleaning procedures, and lower production efficiency, and achieve the effects of improving the utilization rate of glaze water, preventing glaze water precipitation, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

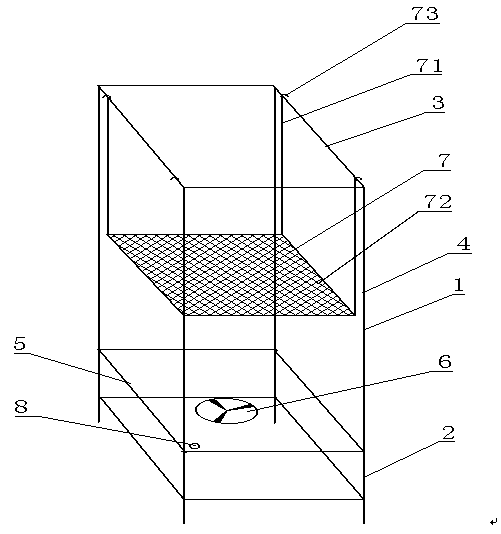

[0018] The invention discloses an energy-saving and environment-friendly glaze scooping device. Compared with the traditional glair scooping device, the focus of the present invention is to add a stirring device, a movable filtering device and drainage holes, which can prevent layered precipitation of the glaze water through stirring , and can conveniently use the movable filter device to clean the rotten body in time, thereby reducing the cleaning frequency of the glaze water device, greatly reducing the pollution of the glaze water, saving energy for the glaze water, and improving the utilization rate of the glaze water and the stability of the quality.

[0019] The present invention will be described in further detail below through specific examples.

[0020] Such as figure 1 As shown, an energy-saving and environment-friendly glaze fishing device includes a glaze bucket 1 and a bracket 2, the glaze bucket 1 is placed on the bracket 2, the glaze bucket 1 has a bucket mouth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com