A kind of biochar-based stable compound fertilizer and preparation method thereof

A biochar and stability technology, applied in fertilization devices, fertilizer mixtures, agricultural gas emission reduction, etc., can solve the problems of not fundamentally exploring the special functions of biochar, ignoring biochar, and the effect of adsorption materials are very different, so as to save The cost of fertilization, the simple and easy preparation method, and the effect of improving the quality of agricultural products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a preparation method for the above-mentioned biochar-based stable compound fertilizer, comprising the following steps:

[0040] (a) Mix the biochar with the humic acid to prepare a first mixture with a water content of 35-45%, leave it at room temperature for 70-75 hours, and dry it until the water content is 18-22%;

[0041] (b) uniformly mixing the dried first mixture with the nitrogen conversion inhibiting material to obtain a second mixture;

[0042] (c), mixing the nitrogen-containing substance, phosphorus-containing substance, potassium-containing substance, viscous minerals, and granulation binder with the second mixture, granulating, and spraying urea-formaldehyde resin for coating after granulation, Then drying to obtain the biochar-based stable compound fertilizer.

[0043] The preparation method of the biochar-based stable compound fertilizer provided by the embodiment of the present invention first mixes the biochar with ...

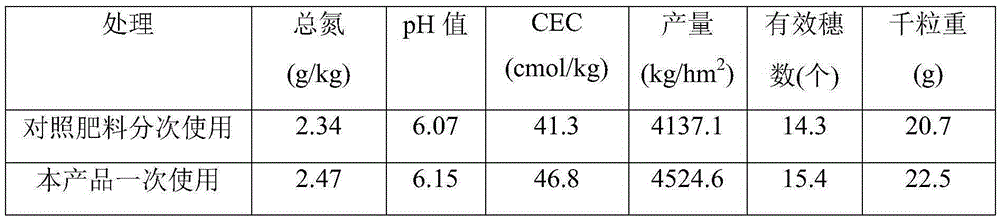

Embodiment 1

[0046] Crush citrus branches, banana stalks, and imperial bamboo grass to a diameter of ≤ 2.5 cm, anaerobically crack them at 500°C for 3 hours, pass through a 200-mesh sieve after crushing, and prepare citrus branches, banana stalks, and imperial bamboo grass The biochar is mixed evenly according to the weight ratio of 1:1:2.5;

[0047] Mix 0.5 parts of biochar mixture with 0.08 parts of humic acid with a pH of 3.8 and pass through a 200-mesh sieve, adjust the water content to 45%, and dry it after standing for 70 hours;

[0048] Then mix homogeneously with 0.02 part of dicyandiamide and 0.025 part of hydroquinone to obtain the second mixture;

[0049] The second mixture is mixed with 45 parts of urea (powder), 15 parts of monoammonium phosphate (powder), 30 parts of potassium chloride (powder), 1 part of attapulgite powder passed through a 200 mesh sieve, 8 parts of a 200 mesh sieve Limestone powder, 0.2 parts of sodium silicate (sprayed after water-soluble) are mixed for d...

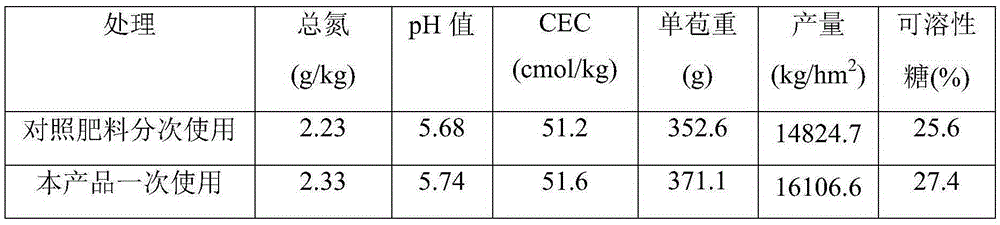

Embodiment 2

[0056] Grind citrus branches, corn stalks, and royal bamboo grass to a diameter of ≤ 2.5 cm, crack anaerobically at 500°C for 2.5 hours, and pass through a 250-mesh sieve after crushing to obtain The biochar is mixed evenly according to the weight ratio of 1:1:2;

[0057] Take 0.9 part of the biochar mixture and mix it with 0.1 part of humic acid with a pH of 4.0 and pass through a 200-mesh sieve, adjust the water content to 35%, and dry it after standing for 70 hours;

[0058] Then mix homogeneously with 0.02 part of dicyandiamide, 0.021 part of N-butyl thiophosphoric triamide (NBPT), obtain the second mixture;

[0059] The second mixture is mixed with 41 parts of urea (powder), 13 parts of monoammonium phosphate (powder), 34 parts of potassium sulfate (powder), 2 parts of attapulgite powder crossed 200 mesh sieve, 7 parts of Limestone powder, 2 parts of zeolite powder, and 0.2 parts of sodium silicate (sprayed after water-soluble) are mixed and granulated by a drum granulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com