Continuous extraction method reclaims the method for methyl ester in esterification waste liquid

An extraction method and esterification technology, which is applied in the field of continuous extraction method to recover methyl ester from esterification waste liquid, can solve the problems of hidden safety and environmental protection, unstable process parameters, high labor intensity, etc., and achieve the elimination of hidden safety and environmental protection hidden dangers. , the effect of reducing the incidence of occupational diseases and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing,

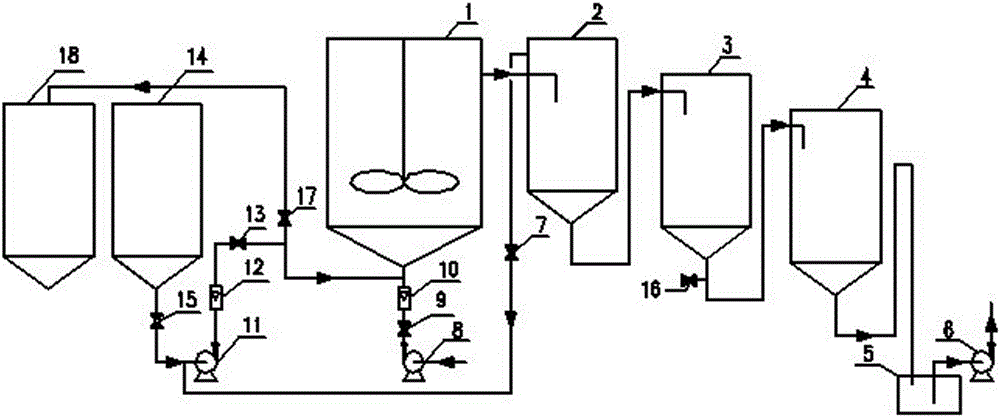

[0016] In the accompanying drawings, the equipment used in the present invention is: the first extraction tank 1 communicates with the second extraction tank 2, the third extraction tank 3 and the fourth extraction tank 4 in sequence. The fourth extraction tank 4 communicates with the ground pool that is connected with the ground pool pump, and the first extraction tank 1 is connected with the esterification waste liquid feed pump 8 through the flow meter 10 connected thereto and the esterification waste liquid feed valve 9, and , the first extraction tank 1 is connected with the secondary settling tank 18 through the secondary settling tank feed valve 17, and is also connected with the pure benzene pump 11 through the pure benzene inlet valve 13 and the pure benzene flow meter 12, and the pure benzene pump 11 It is connected to the pure benzene stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com