Synthesis method of high-density polyvinyl butyral resin

A technology of polyvinyl butyral resin and synthesis method, which is applied in the direction of chemical/physical/physicochemical fixed reactors, etc., and can solve problems such as unstable feeding, unwinding, and overhead equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

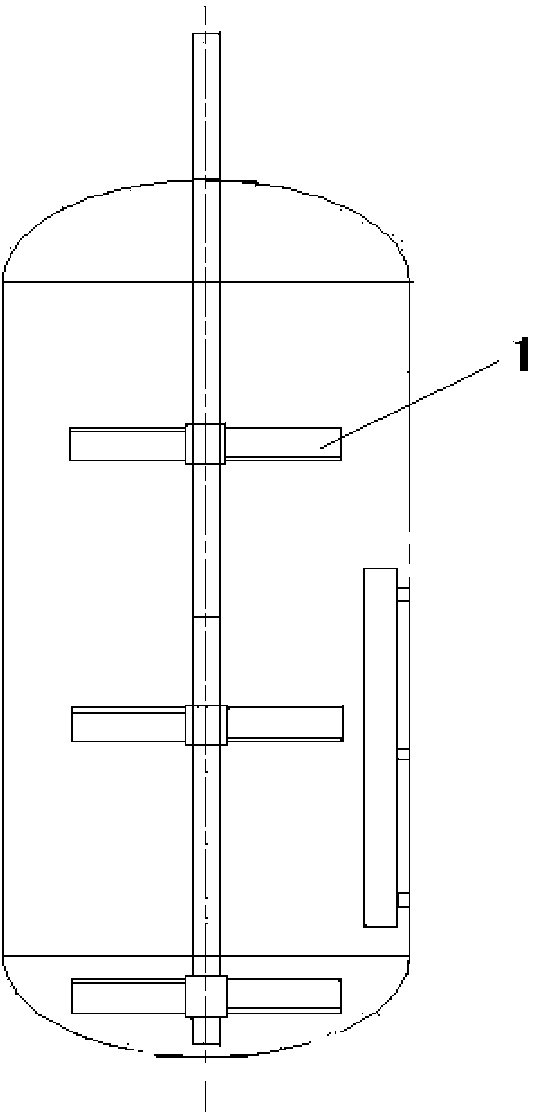

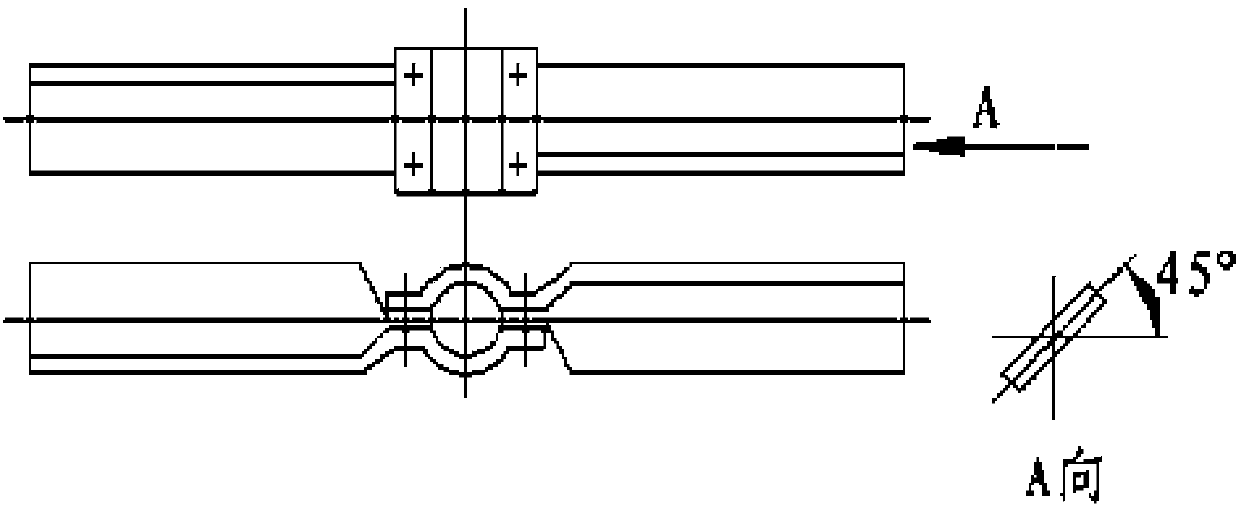

[0032] 300kg of PVA solids were dropped into 4315kg of pure water, and the temperature was raised to 97° C. to make a PVA aqueous solution with a solution mass fraction of 6.5%. Cool down to 50-60 degrees and pump the PVA solution into the figure 1 , 2 In the condensation reaction kettle shown, the reaction kettle has three layers of two-bladed paddles 1; the paddles 1 are inclined at a certain angle, and the angle between them and the horizontal plane is 45°; the reaction kettle also has two pieces symmetrically installed at 0 degrees -180 degrees away from the wall plate baffle structure; the stirring motor of the reactor is transformed into a variable frequency speed regulating motor. Start stirring and increase the speed to 110r / min, add 171KG n-butyraldehyde solution, continue to cool down to 35-45 degrees to obtain polyvinyl alcohol / n-butyraldehyde mixed solution; when the temperature is 22.5°C, add hydrochloric acid solution (its pure The mass ratio of mass to PVA is ...

Embodiment 2

[0034] 300kg of PVA solids were dropped into 3986kg of pure water, and the temperature was raised to 95° C. to make a PVA aqueous solution with a solution mass fraction of 7.0%. Cool down to 50-60 degrees and pump the PVA solution into figure 1 , 2 In the said condensation reactor. Start stirring and raise the rotating speed to 95r / min, add 171KG n-butyraldehyde solution, continue to cool down to 35-45 degrees to obtain polyvinyl alcohol / n-butyraldehyde mixed solution; when the temperature is 24°C, add hydrochloric acid solution (its pure The mass ratio of mass to PVA is 0.2), then the temperature is raised and maintained at 82°C; after the reaction is completed, add sodium hydroxide solution to fully neutralize it, then wash with pure water, centrifuge, and dry.

Embodiment 3

[0036] 300kg of PVA solids were dropped into 3700kg of pure water, and the temperature was raised to 96.5° C. to make a PVA aqueous solution with a solution mass fraction of 7.5%. Cool down to (50-60) degrees and pump the PVA solution into figure 1 , The condensation reactor shown in 2. Start stirring and increase the speed to 100r / min, add 171KG n-butyraldehyde solution, continue to cool down to (35-45) degrees to obtain polyvinyl alcohol / n-butyraldehyde mixed solution; when the temperature is 23.5°C, add hydrochloric acid solution (the The mass ratio of pure mass to PVA is 0.2), and then the temperature is raised to maintain at 86.5°C; after the reaction is completed, add sodium hydroxide solution to fully neutralize it, then wash with pure water, centrifuge, and dry to obtain .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Melt mass flow rate | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com