Natural silk anti-crease agent and preparation method and application thereof

An anti-wrinkle agent and real silk technology, applied in textiles and papermaking, fiber treatment, animal fiber, etc., can solve the problems that the anti-wrinkle performance of finished fabrics has not been involved, and achieve the effect of remarkable anti-wrinkle effect, simple and easy-to-obtain raw materials, and improve affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

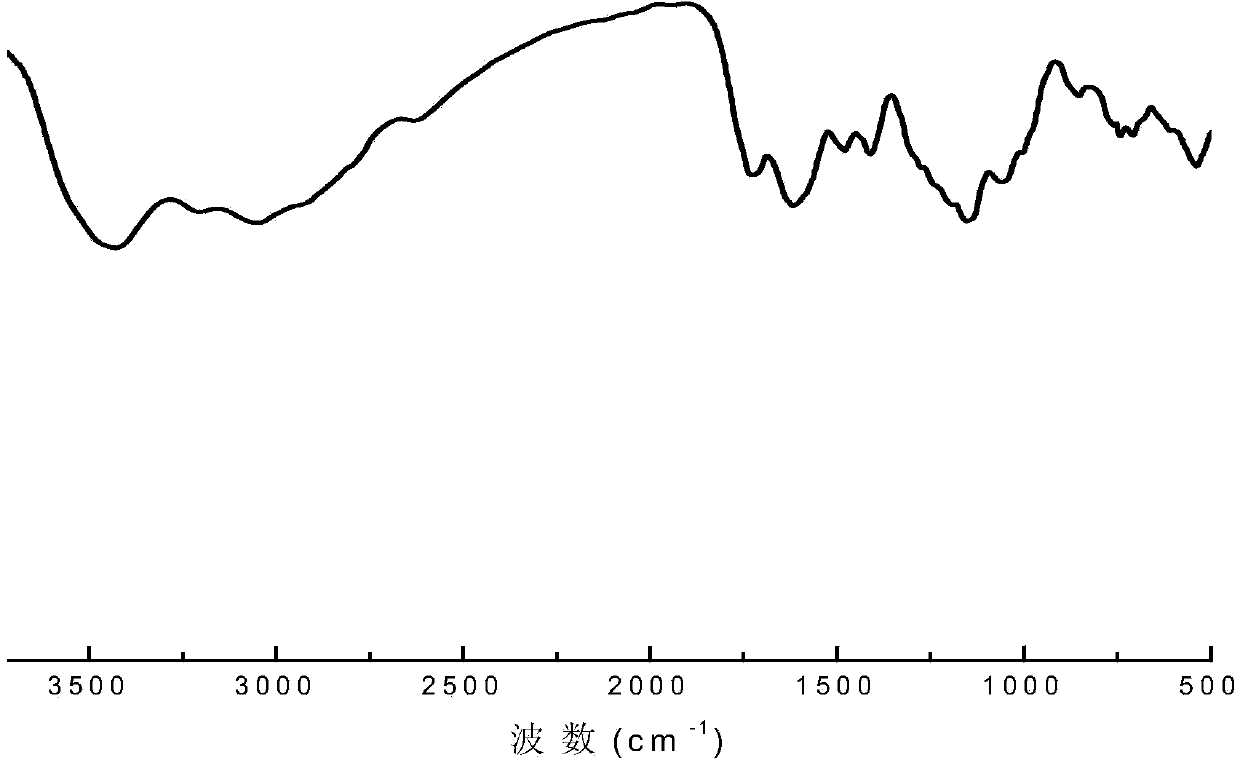

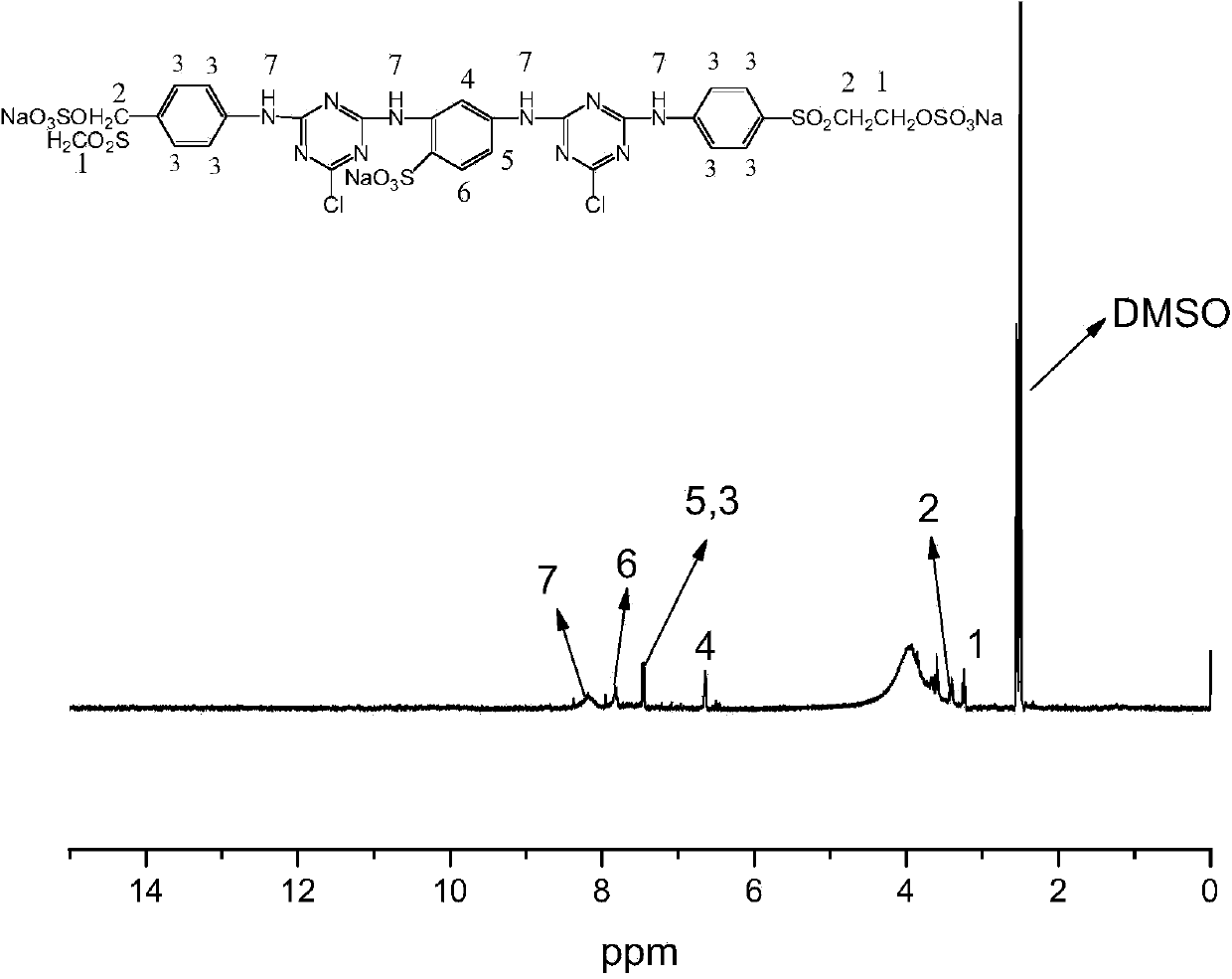

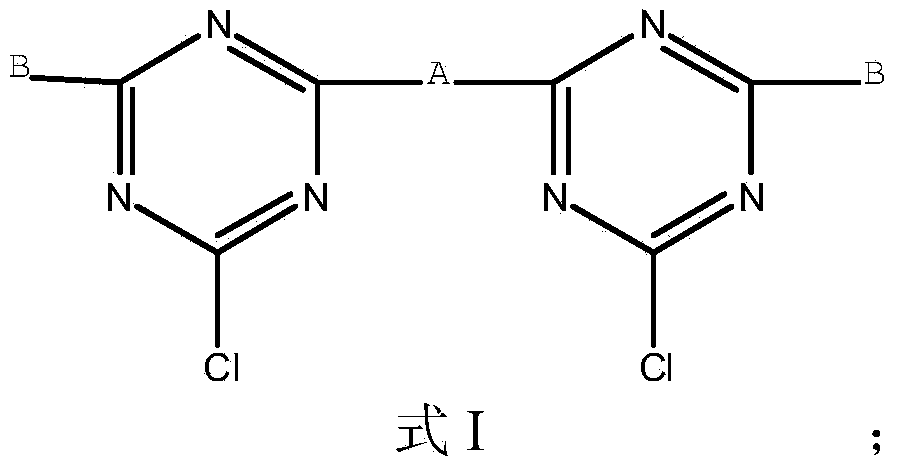

Method used

Image

Examples

Embodiment 1

[0035] 1. Dissolution of cyanuric chloride

[0036] In a reaction flask equipped with a stirrer and a thermometer, add 20.24g (0.1mol) of cyanuric chloride, dissolve with acetone and ice water [choose 20mL ice water and 10mL acetone], and stir mechanically for 10min to promote its full dissolution.

[0037] 2. Add 2,4-diaminobenzenesulfonic acid [choose 9.4g (0.05mol)] into 40mL of water, and slowly (3min) add sodium carbonate powder (0.05mol) of the same amount while stirring, and the addition of sodium carbonate is completed Afterwards, continue to stir for 5 minutes to change 2,4-diaminobenzenesulfonic acid into sodium 2,4-diaminobenzenesulfonate (0.05mol) to obtain an aqueous solution of sodium bisaminobenzenesulfonate.

[0038] 3. Slowly add an aqueous solution of sodium bisaminobenzenesulfonate dropwise (2 drops / 1 second) into the three-necked flask dissolved with cyanuric chloride system for the first condensation reaction, the reaction temperature is 3°C, and the react...

Embodiment 2

[0053] 1. Dissolution of cyanuric chloride

[0054] In a reaction flask equipped with a stirrer and a thermometer, add 20.24g (0.1mol) of cyanuric chloride, dissolve with acetone and ice water [choose 20mL ice water and 10mL acetone], and stir mechanically for 10min to promote its full dissolution.

[0055] 2. Add 2,5-diaminobenzenesulfonic acid [choose 9.4g (0.05mol)] into 40mL water, and slowly add sodium carbonate powder (0.05mol) of equal amount under stirring. After adding sodium carbonate, continue Stir for 5 minutes to change 2,5-diaminobenzenesulfonic acid into sodium 2,5-diaminobenzenesulfonate (0.05mol) to obtain an aqueous solution of sodium diaminobenzenesulfonate.

[0056] 3. Add an aqueous solution of sodium bisaminobenzenesulfonate slowly dropwise (2 drops / 1 second) into the three-necked flask in which the cyanuric chloride system is dissolved for the first condensation, the reaction temperature is 0°C, and the reaction time is 8 hours. During the whole reactio...

Embodiment 3

[0065] 1. Dissolution of cyanuric chloride

[0066] In a reaction flask equipped with a stirrer and a thermometer, add 20.24g (0.1mol) of cyanuric chloride, dissolve with acetone and ice water [choose 20mL ice water and 10mL acetone], and stir mechanically for 10min to promote its full dissolution.

[0067] 2. Add 2,5-diaminobenzenesulfonic acid [choose 9.4g (0.05mol)] into 40mL water, and slowly add sodium carbonate powder (0.05mol) of equal amount under stirring. After adding sodium carbonate, continue Stir for 5 minutes to change 2,5-diaminobenzenesulfonic acid into sodium 2,5-diaminobenzenesulfonate to obtain an aqueous solution of sodium bisaminobenzenesulfonate.

[0068] 3. Slowly add an aqueous solution of sodium bisaminobenzenesulfonate dropwise (2 drops / 1 second) into the three-necked flask dissolved with cyanuric chloride system for the first condensation, the reaction temperature is 5°C, and the reaction time is 4 hours. During the entire reaction process, potassiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com