A test bench for oil injection pump and cooling pump

A technology for oil return pump and cooling pump, which is used in pump testing, liquid variable capacity machinery, machines/engines, etc. It can solve the problems of high price, high noise, complicated operation, etc., and achieve strong corrosion resistance and stable performance. , measure the precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

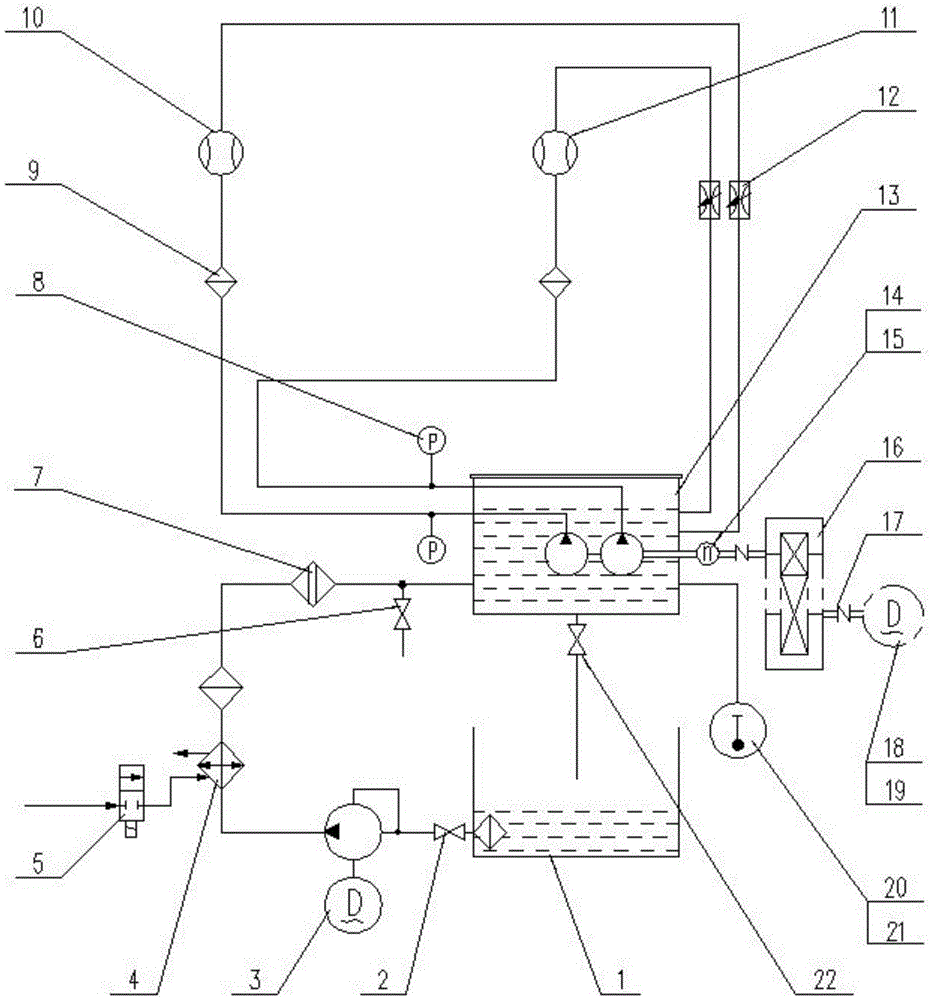

[0016] This embodiment provides a test bench for oil injection and return pumps and cooling pumps, the structure of which is as follows: figure 1 As shown, it includes lower oil tank 1, working oil tank 13, magnetoelectric speed sensor 14, speed increasing box 16, coupling 17, frequency conversion speed regulating motor 18, temperature sensor 20 and oil discharge switch 22, and lower oil tank 1 is located at working oil tank 13 The bottom is connected to the working oil tank 13, the oil drain switch 22 is connected to the bottom of the working oil tank 13 and the outlet faces the lower oil tank 1, the temperature sensor 20 is connected to the side wall of the working oil tank 13, the frequency conversion motor 18 is connected to the input end of the coupling 17, and the coupling The output end of 17 is connected to the input end of speed-up box 16, and the output end of speed-up box 16 is connected to magnetoelectric speed sensor 14 through coupling, and magnetoelectric speed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com