Energy feedback type self-sensing magnetorheological damper

A magneto-rheological shock absorber, self-sensing magnetic technology, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problem of large volume of energy conversion mechanism and state feedback sensor, damping force and dynamic Problems such as limited damping ratio range and low utilization rate of magnetorheological fluid can achieve the effects of improving energy conversion efficiency, easy protection, and increasing the range of dynamic damping ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

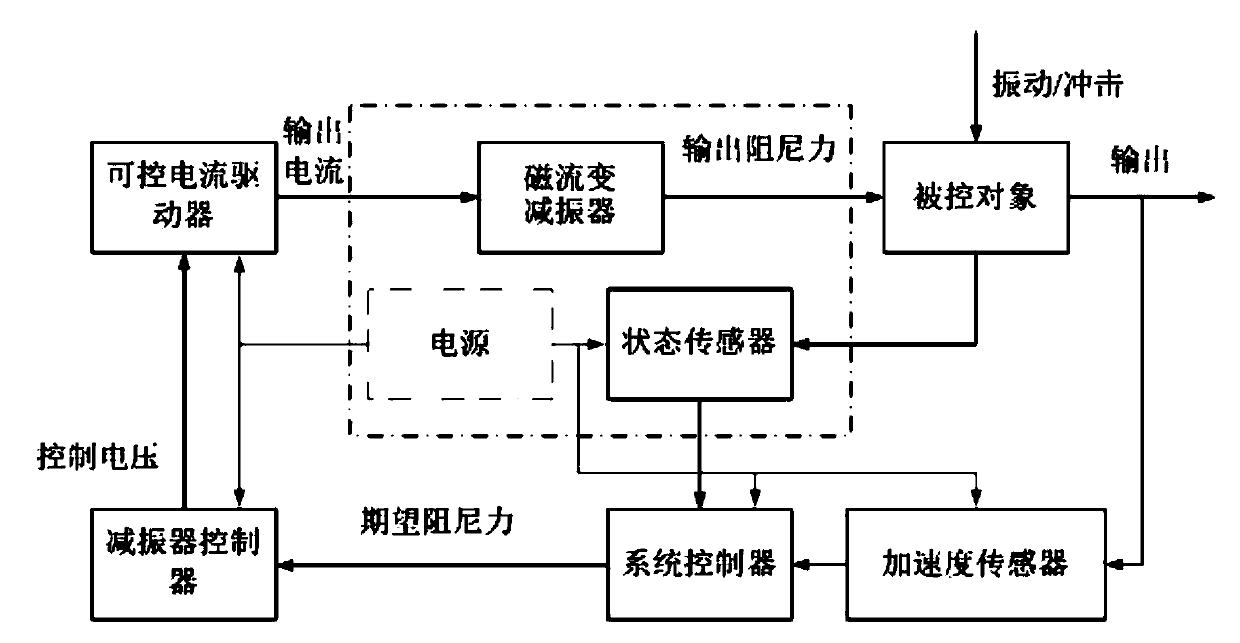

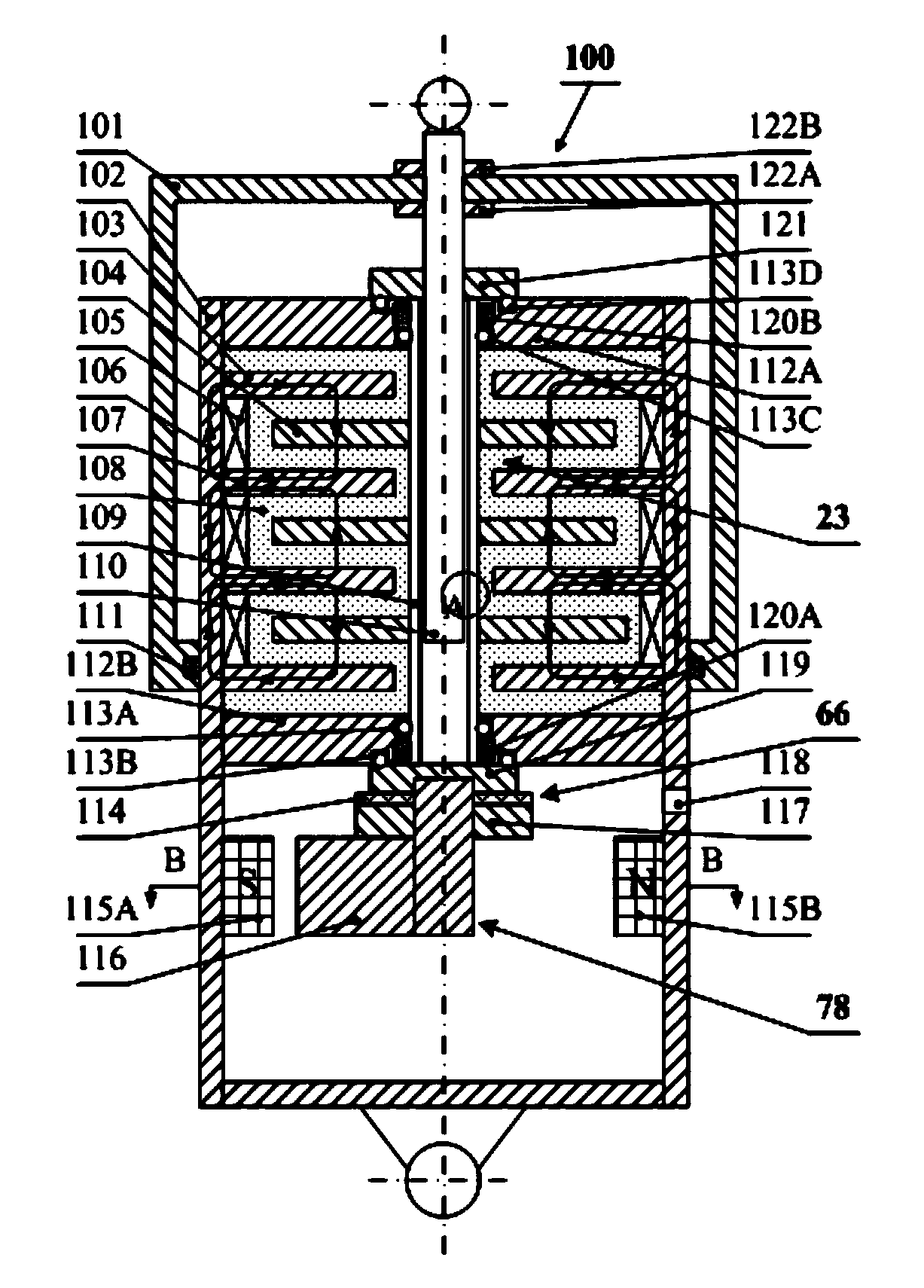

[0041] see Figure 2A , Figure 2B and Figure 2C In this embodiment, the energy-feeding self-sensing magneto-rheological shock absorber 100 includes a pure shear magneto-rheological shock absorber 23 , an energy-feeding mechanism 78 for converting mechanical energy into electrical energy, and a rotational speed sensor 66 .

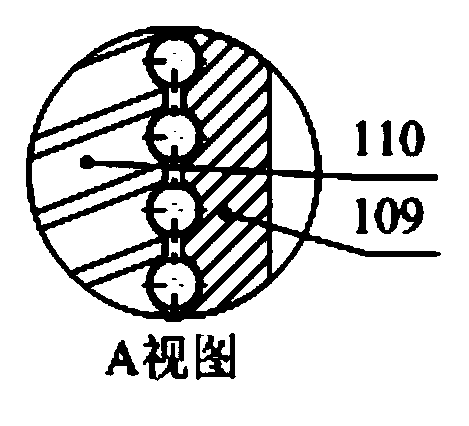

[0042] like Figure 2A and Figure 2B As shown, the pure shear magnetorheological shock absorber 23 in this embodiment includes an outer cylinder 101, an inner cylinder 102 and a ball screw pair, and the outer cylinder 101 and the inner cylinder 102 are arranged coaxially; The screw 110 used as the piston rod in the ball screw pair is fixed at one end to the center of the end cover of the outer cylinder 101 by an inner nut 122A and an outer nut 122B, and can be compressed into or restored to exit the inner cylinder 102. The inner wall of the inner cylinder 102 is provided with electromagnetic coils 105 corresponding to the shearing discs 104 one by on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com