Torsional vibration signal detection method and device for engine crankshaft

A signal detection and engine technology, which is used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of inability to obtain stable and effective torsional vibration signals, poor adaptability, and unsuitable for engine crankshaft torsional vibration signal acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

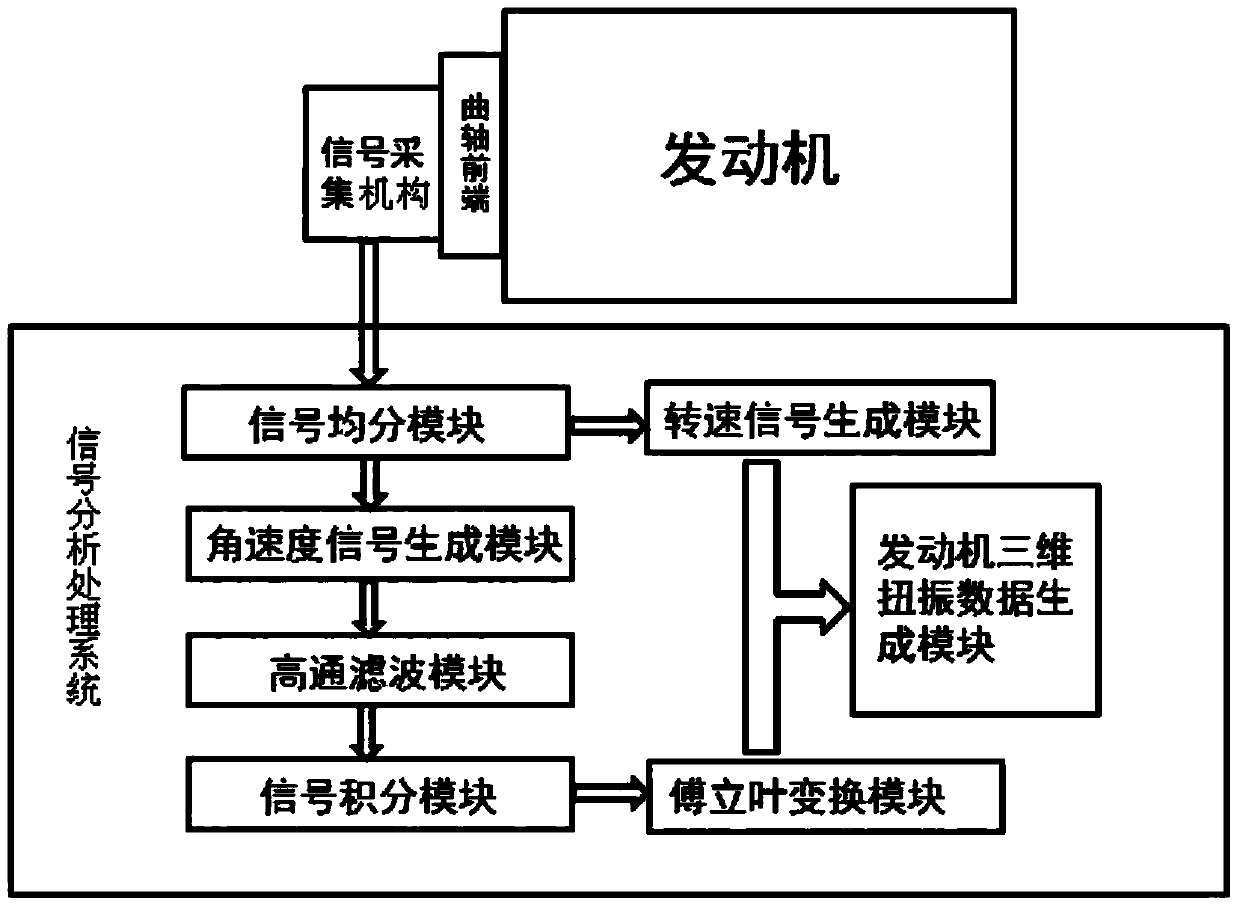

[0046] The examples of the present invention will be further described below in conjunction with the accompanying drawings. A kind of engine crankshaft torsional vibration signal detection method of the present invention is characterized in comprising the following steps:

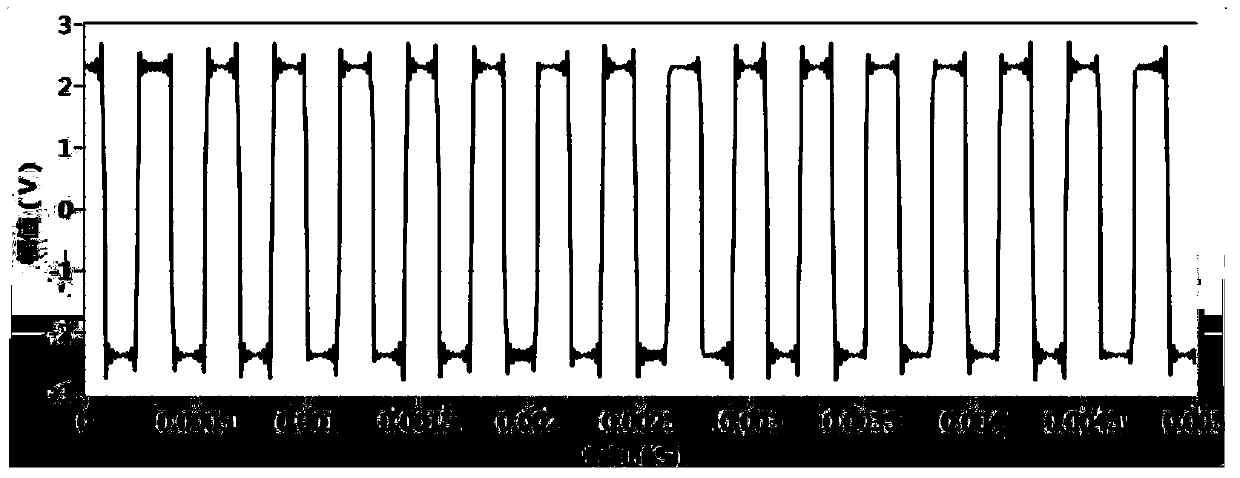

[0047] 1) Use the encoder of the signal acquisition mechanism to collect the rotation pulse signal Q of the front end of the engine crankshaft whose time is T, where T is an integer multiple of R, and divide the signal into pulse signals with each period of time R Q k , k = 1,2 , · · · , T R ; Such as figure 2 ;

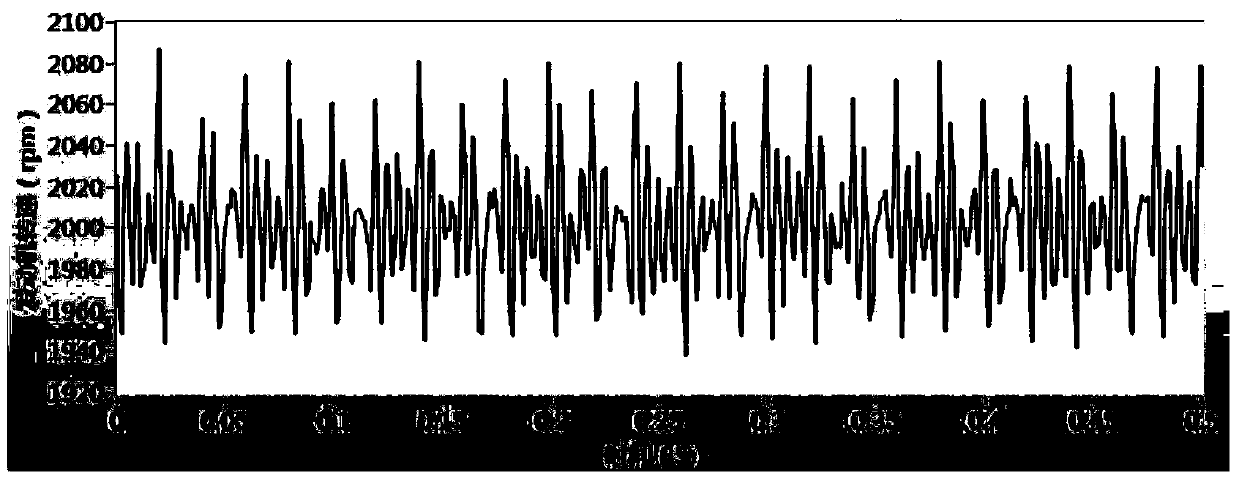

[0048] 2) Divide the pulse signal Q equally k Converted to a speed signal n k and the angular velocity signal ω k According to the following formula: n k = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com