Friction Loading Device for Load Simulation of Front Swing Center Nozzle

A load simulation and loading device technology, which is applied in the testing of measuring devices, instruments, and mechanical components, can solve problems such as the inability to simulate the load characteristics of the front swing center nozzle, the difficulty in designing the load simulation system, and the low accuracy of friction torque loading. Achieve the effect of good loading accuracy, stable friction coefficient and convenient torque calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

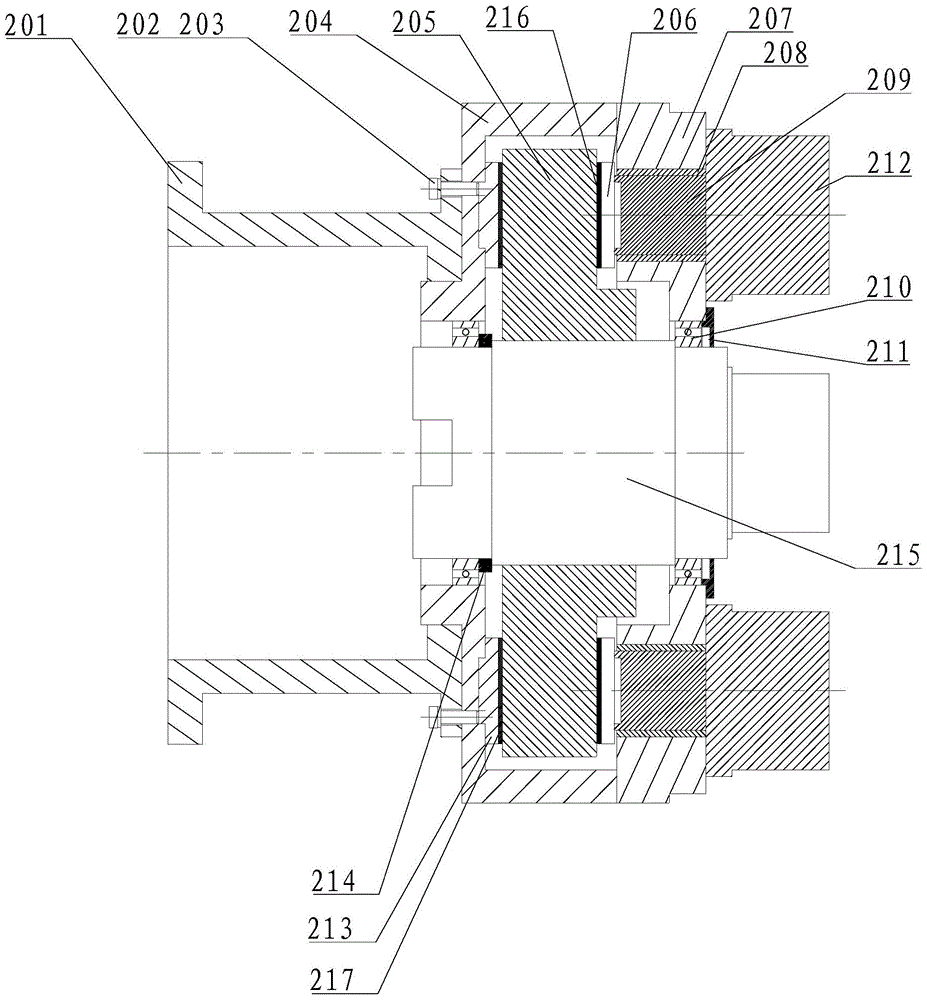

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

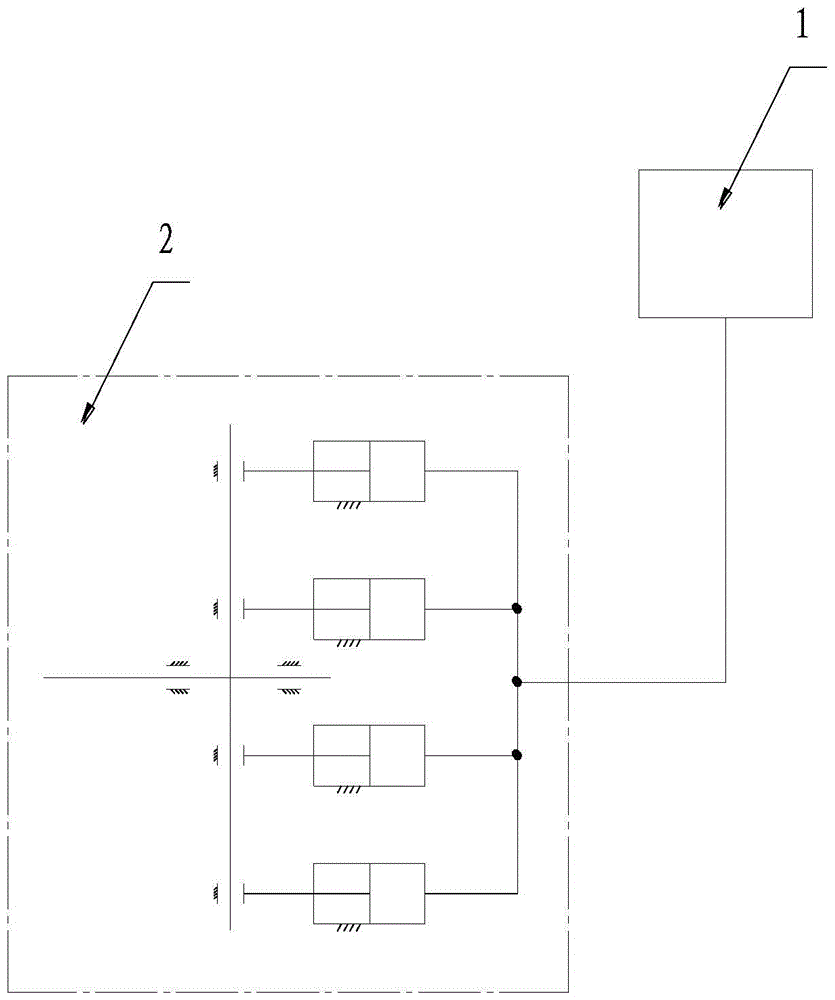

[0022] like figure 1 As shown, a front swing center nozzle load simulation friction loading device provided by the present invention includes a friction loading hydraulic system 1 and a friction loading mechanism 2 communicating with the friction loading hydraulic system 1 . The friction loading hydraulic system 1 provides hydraulic power for the friction loading mechanism 2 .

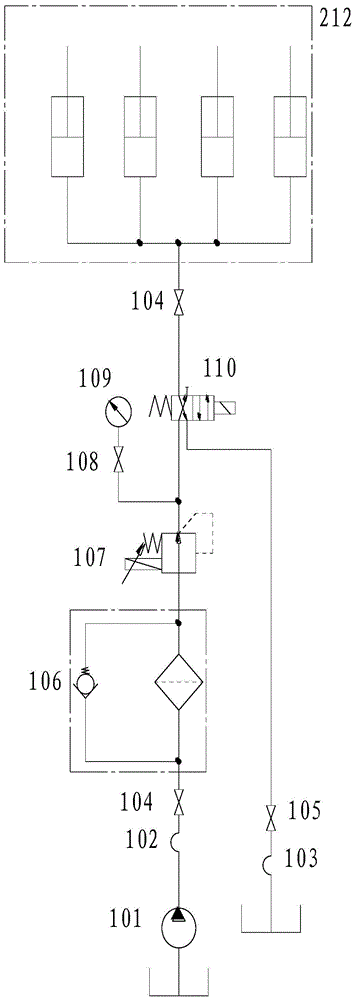

[0023] like figure 2 As shown, the friction loading hydraulic system 1 is composed of an oil source 101, an oil hose 102, an oil return hose 103, a high pressure ball valve 104, a low pressure ball valve 105, a high pressure filter 106, a proportional pressure reducing valve 107, a pressure gauge switch 108, a pressure gauge 109. Electromagnetic reversing valve 110 is formed. The oil outlet of the oil source 101 communicates with the input end of the high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com