Mechanical vibration fault characteristic time domain blind extraction method

A technology of fault characteristics and mechanical vibration, used in mechanical bearing testing, special data processing applications, instruments, etc., can solve problems such as sequence uncertainty, blind separation result sequence uncertainty, affecting the effect of blind separation, etc., to reduce the impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

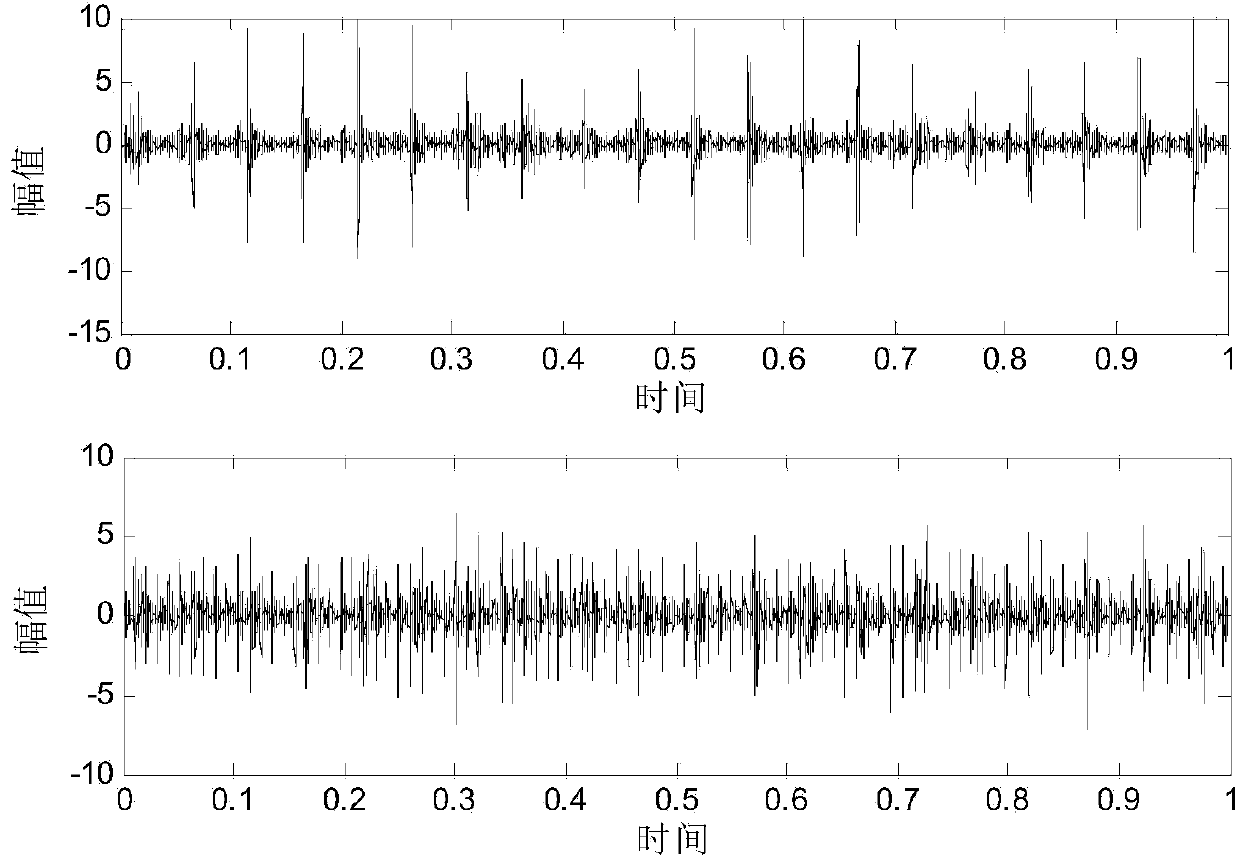

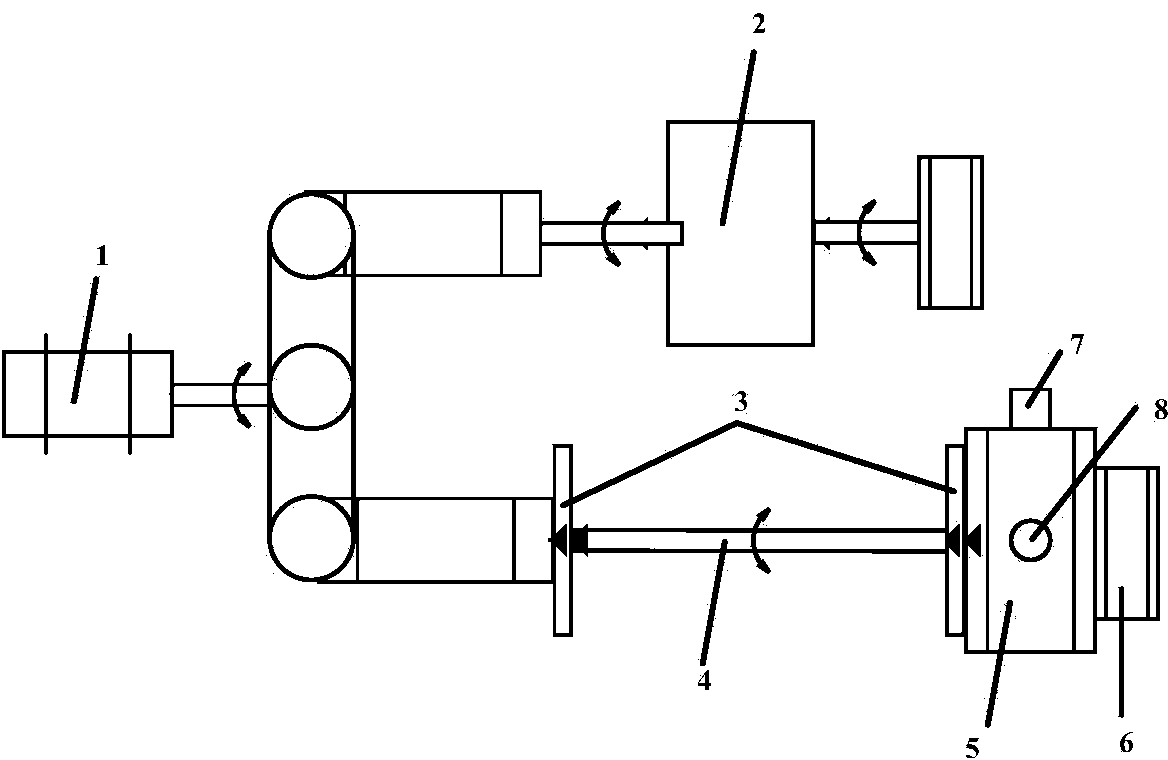

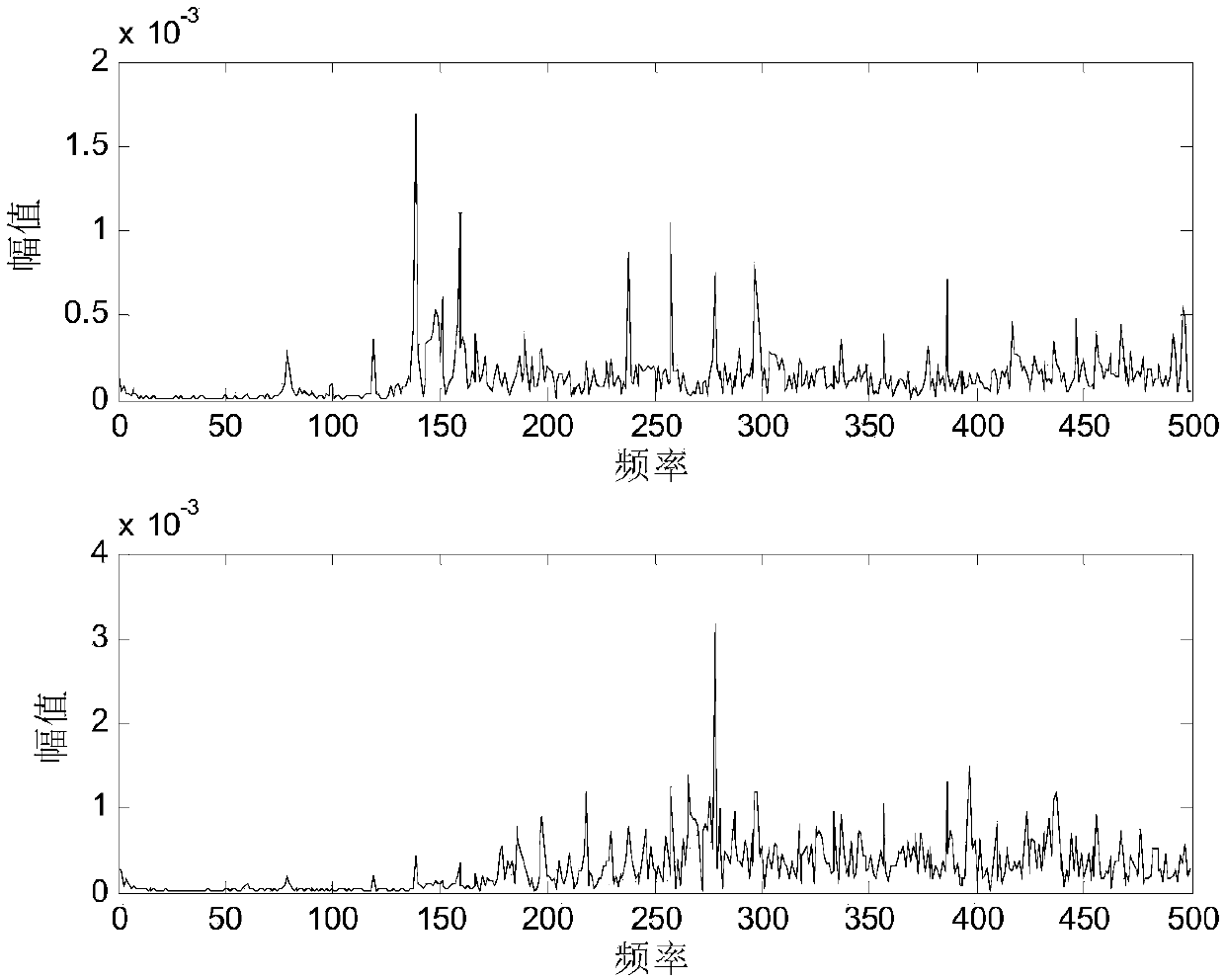

[0036] Embodiment 1: as Figure 1-8 As shown, a mechanical vibration fault feature time domain blind extraction method, the specific steps of the mechanical vibration fault feature time domain blind extraction method are as follows:

[0037] Step1, initialization delay parameter L, number of principal components n pc , the number of clusters n cluster ;

[0038] Step2. Centralized processing The signal x(t) is obtained from the vibration observation signal x(t) received by the acceleration sensor, and the high-dimensional subspace signal x'(t) is formed by zero padding, and the high-dimensional subspace signal x'(t) is processed PCA principal component analysis to obtain low-dimensional signal x(t) pc ;

[0039] Step3, for the low-dimensional signal x(t) obtained in step Step2 pc Execute the FastICA independent component analysis algorithm to obtain the independent component ic(t), and calculate the normalized kurtosis kurt of the independent component ic(t) ic and find ...

Embodiment 2

[0056] Embodiment 2: as Figure 1-8 As shown, a time-domain blind extraction method of mechanical vibration fault characteristics, this embodiment is the same as Embodiment 1, the difference is that this specific embodiment is based on the composite fault diagnosis experiment of the inner and outer rings of the bearing in a rotating test bench. Example:

[0057] figure 1 Indicates the installation positions of the two acceleration sensors on the test bench, figure 1 In the figure, a pair of PCB acceleration sensors are installed vertically on the bearing housing to pick up vibration signals. The relevant parameters of the faulty bearing are: pitch circle diameter D=39mm, rolling body diameter d=7.5mm, rolling body number Z=12, contact angle α=0°. The spindle in the inner ring of the bearing rotates and the outer ring is fixed. In embodiment 2, the rotating speed is 1200r / min, that is, the rotational frequency f r When it is 20Hz, the sampling frequency fs=8192Hz, the numb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch circle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com