Aero Engine Speed Test System

A technology of aero-engine and test system, applied in the direction of linear/angular velocity measurement, velocity/acceleration/shock measurement, measuring device, etc., can solve the problem of non-compliance with safety and reliability requirements, poor rotational speed measurement accuracy, and intelligent degree low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

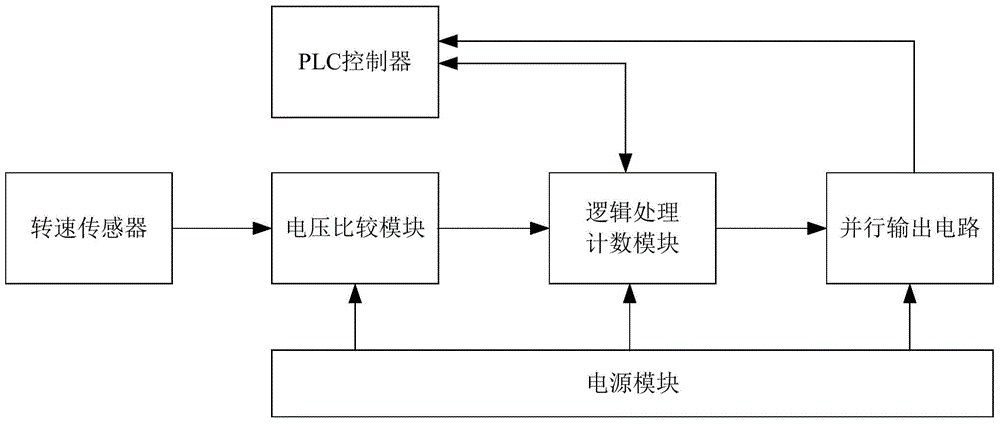

[0018] join figure 1 , an aero-engine speed testing system, comprising: a speed sensor, a voltage comparison module, a logic processing counting module, a PLC controller, a parallel output module and a power supply module;

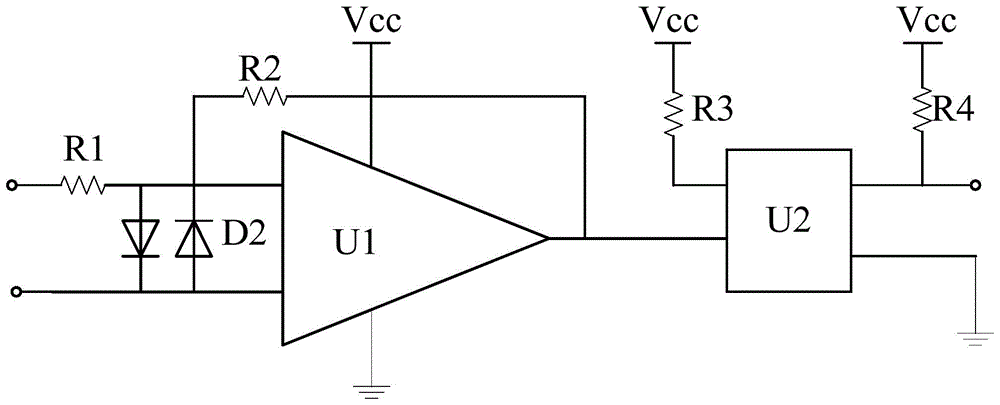

[0019] The input end of the speed sensor is connected with the high and low pressure rotor through the high-speed gearbox of the aero-engine, and is used to detect the speed signal output by the aero-engine, and the output end of the speed signal of the speed sensor is electrically connected with the voltage comparison module; The sensor includes two speed measurement systems. One is to measure the high-pressure speed sensor at the high-pressure rotor end of the engine. The high-pressure speed sensor is connected to the high-pressure rotor through the high-speed gearbox of the aero-engine to measure the speed of the high-pressure rotor end of the aero-engine. The other is to measure the low-pressure speed of the engine. The low-pressure speed sensor at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com