Piezoelectric tilt lens high-voltage driver with object frequency characteristic compensation function

A technology of frequency characteristics and tilt mirrors, applied in the directions of instruments, optical components, optics, etc., can solve the problems of still existing piezoelectric tilt mirror mechanical resonance phenomenon, analog filter network circuit parameter drift, limiting engineering practicability, etc., to improve engineering Practicality, providing versatility, low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

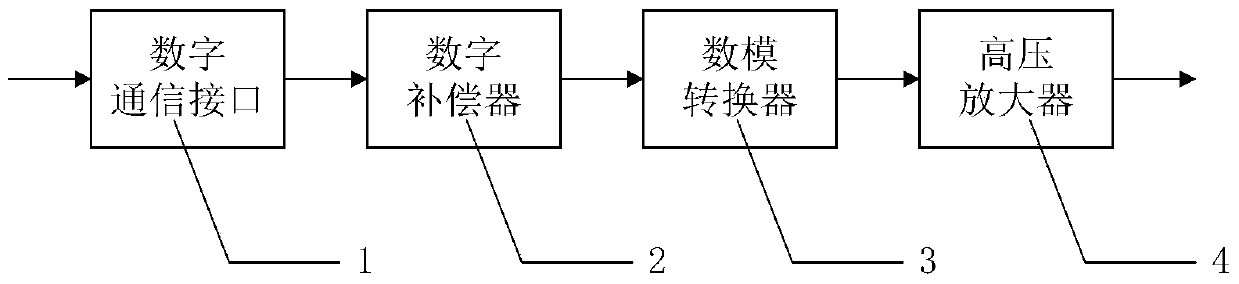

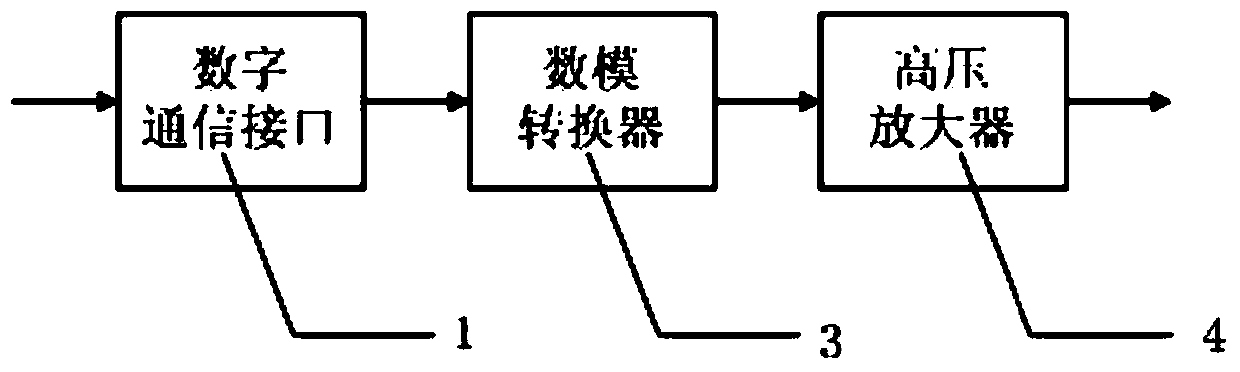

[0019] like figure 1 As shown, the piezoelectric tilting mirror high-voltage driver with the compensation function of the target frequency characteristic of the present invention includes a communication interface 1 , a digital compensator 2 , a digital-to-analog converter 3 and a high-voltage amplifier 4 .

[0020] In this embodiment, the communication interface 1 receives the 16-bit digital control voltage signal sent by the wavefront processor through the CAMERALINK interface, and after digital compensation is performed by the digital compensator 2, it is output to the digital-to-analog converter 3 for 16-bit digital-to-analog conversion The device 3 converts the digital signal into an analog signal of -5V~+5V and outputs it to the high-voltage amplifier 4. After being amplified 100 times by the high-voltage amplifier 4, it outputs a high v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com