Extrusion-resistant and thermal-insulating type electrical power cable

A power cable and cable technology, which is applied in the direction of insulated cables, power cables with shielding layers/conductive layers, cables, etc., can solve the problems of increased design of power cables, poor structural stability, and poor compressive performance, and achieve Improved safety level, good extrusion resistance, and the effect of improving extrusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

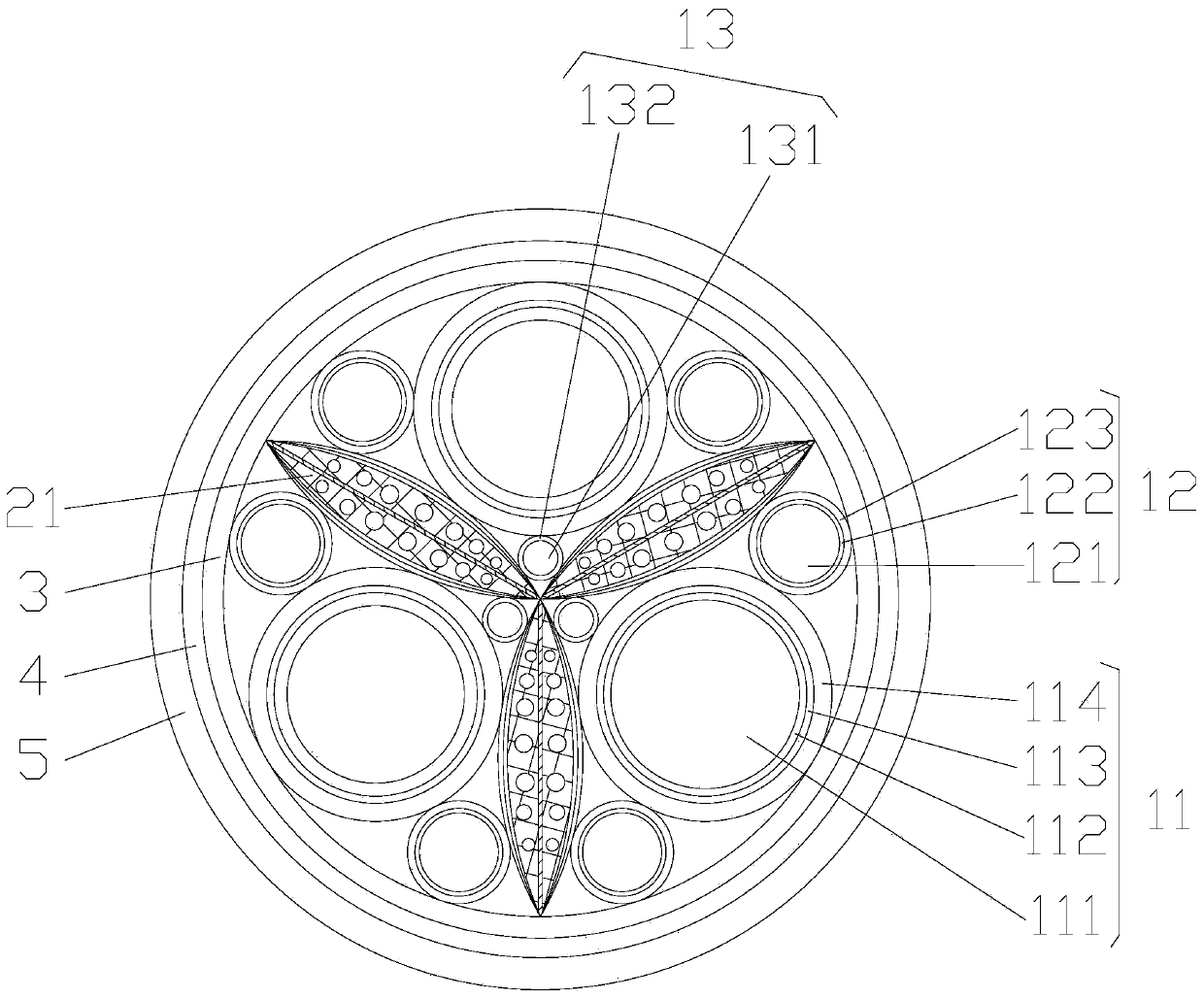

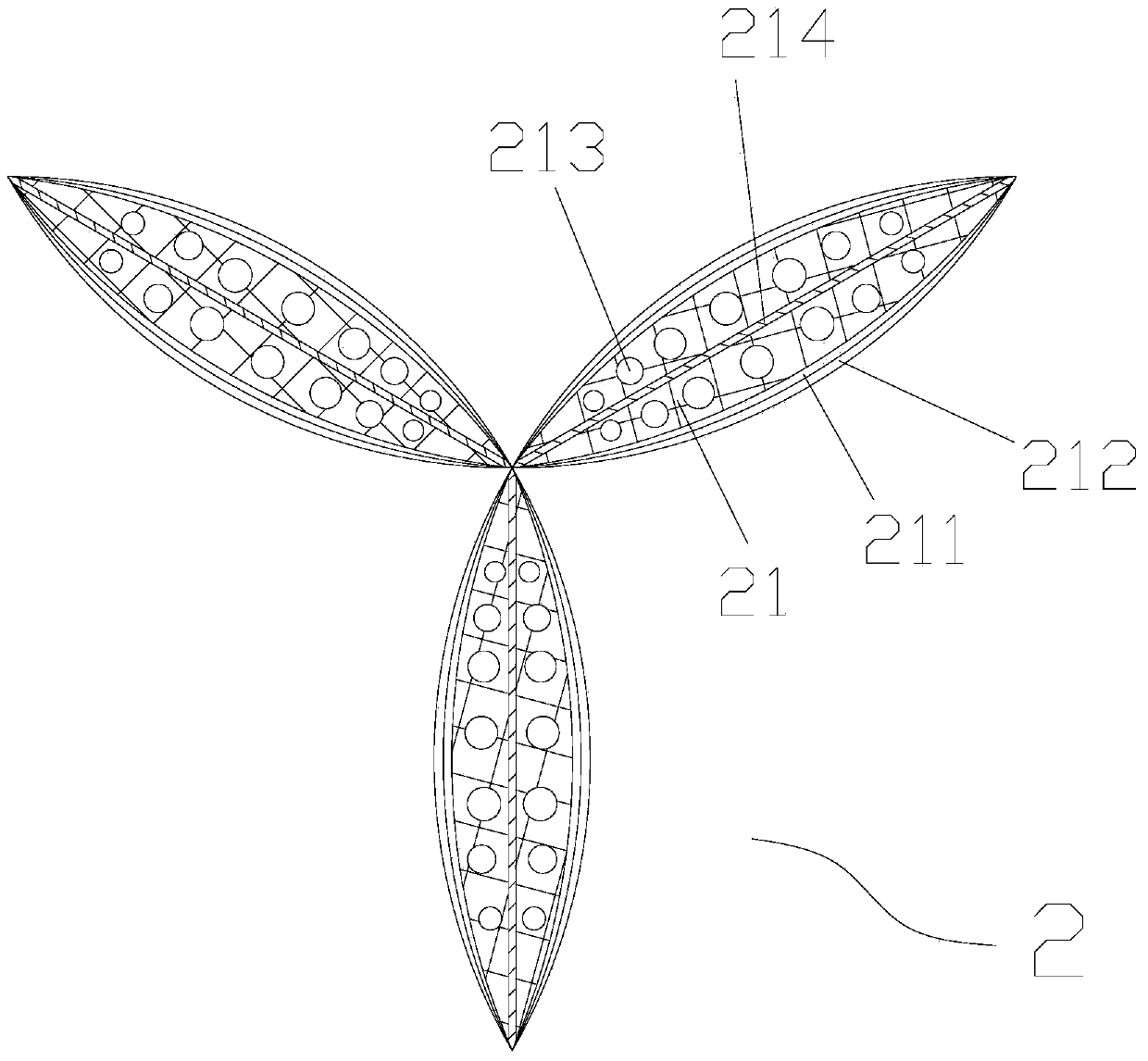

[0012] Such as figure 1 , figure 2 as shown, figure 1 It is a schematic cross-sectional structure diagram of a pressure-resistant and heat-insulated power cable proposed by the present invention; figure 2 It is a schematic cross-sectional structure diagram of an elastic filler frame in a pressure-resistant and heat-insulated power cable proposed by the present invention.

[0013] refer to figure 1 , figure 2 , a pressure-resistant and heat-insulated power cable proposed by the present invention, including a cable core composed of three first conductors 11, six second conductors 12 and an elastic filler frame 2, the elastic filler frame 2 is arranged on the axis of the cable Each first conductor 11 is separated at the core, and the elastic filler frame 2 includes filler strips 21 with an olive-shaped cross section. The filler strips 21 are arranged radially along the cable and meet at the center of the cable core at one end. A thermal insulation coating 211 and a shield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com