Plated member, plated terminal for connectors, method for producing plated member, and method for producing plated terminal for connectors

一种制造方法、连接器的技术,应用在接触件制造、化学仪器和方法、接触部件等方向,能够解决端子插入力增大、摩擦系数上升、晶粒易粗大等问题,达到容易摩擦系数、摩擦系数降低、降低制造成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

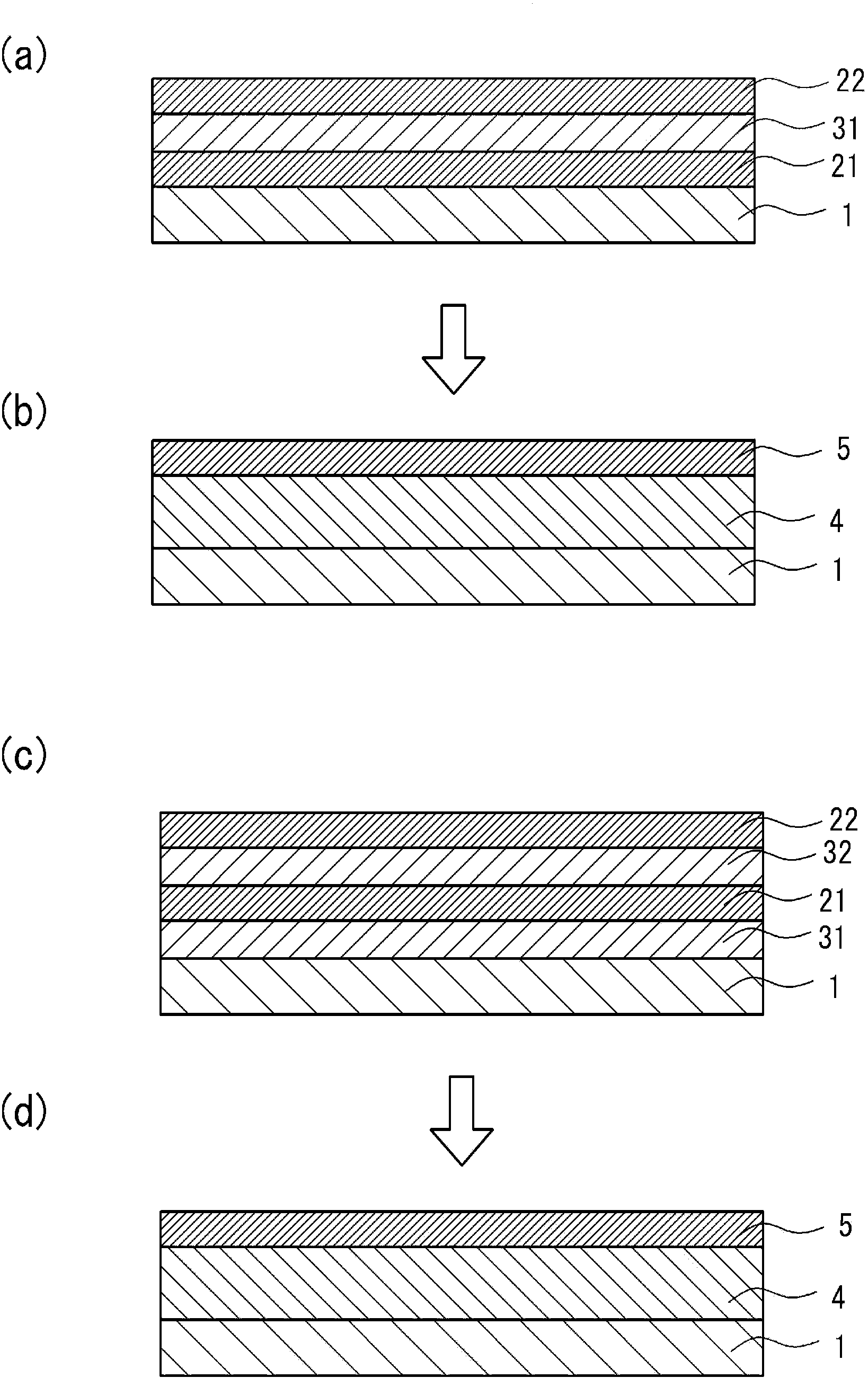

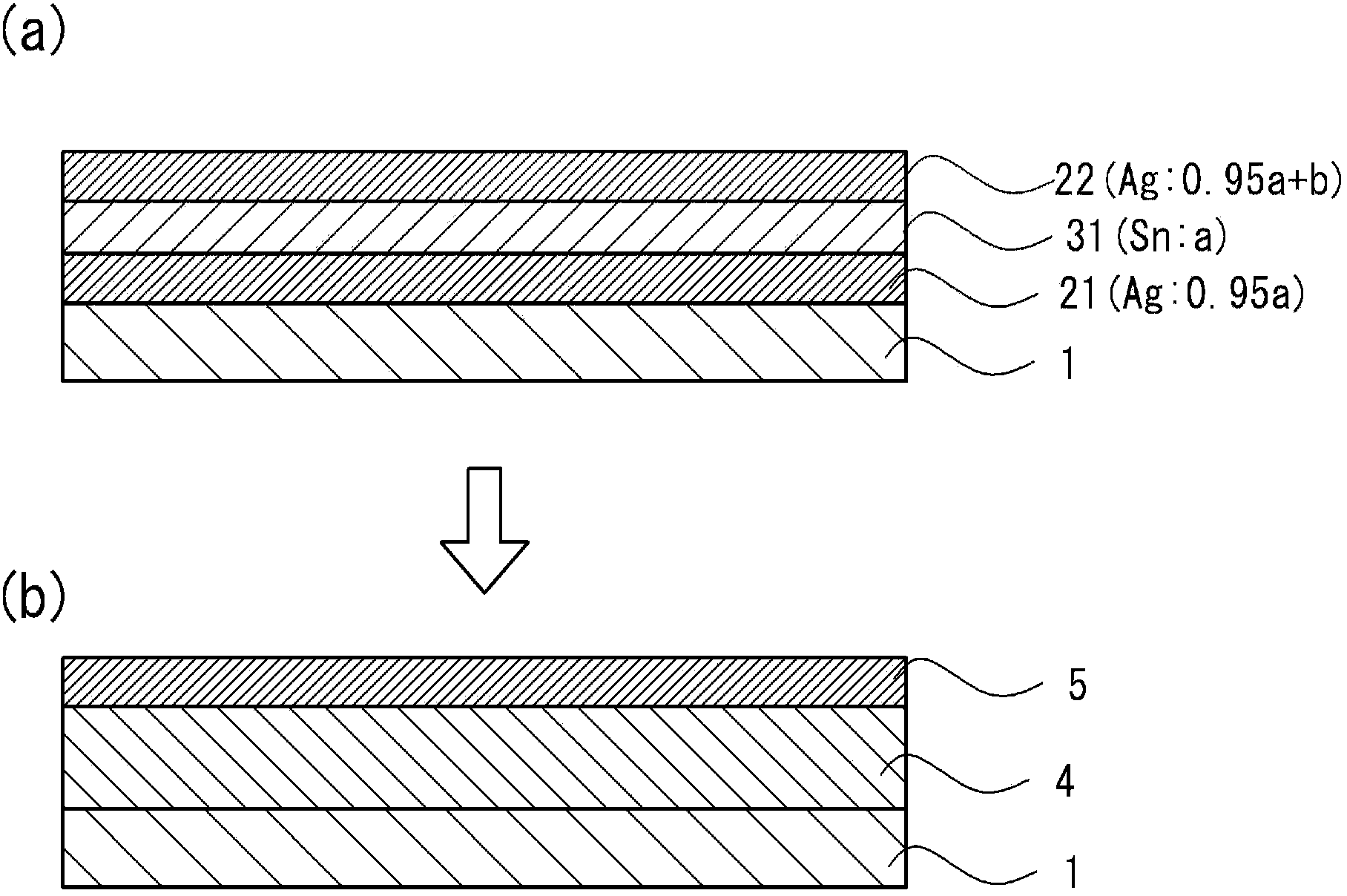

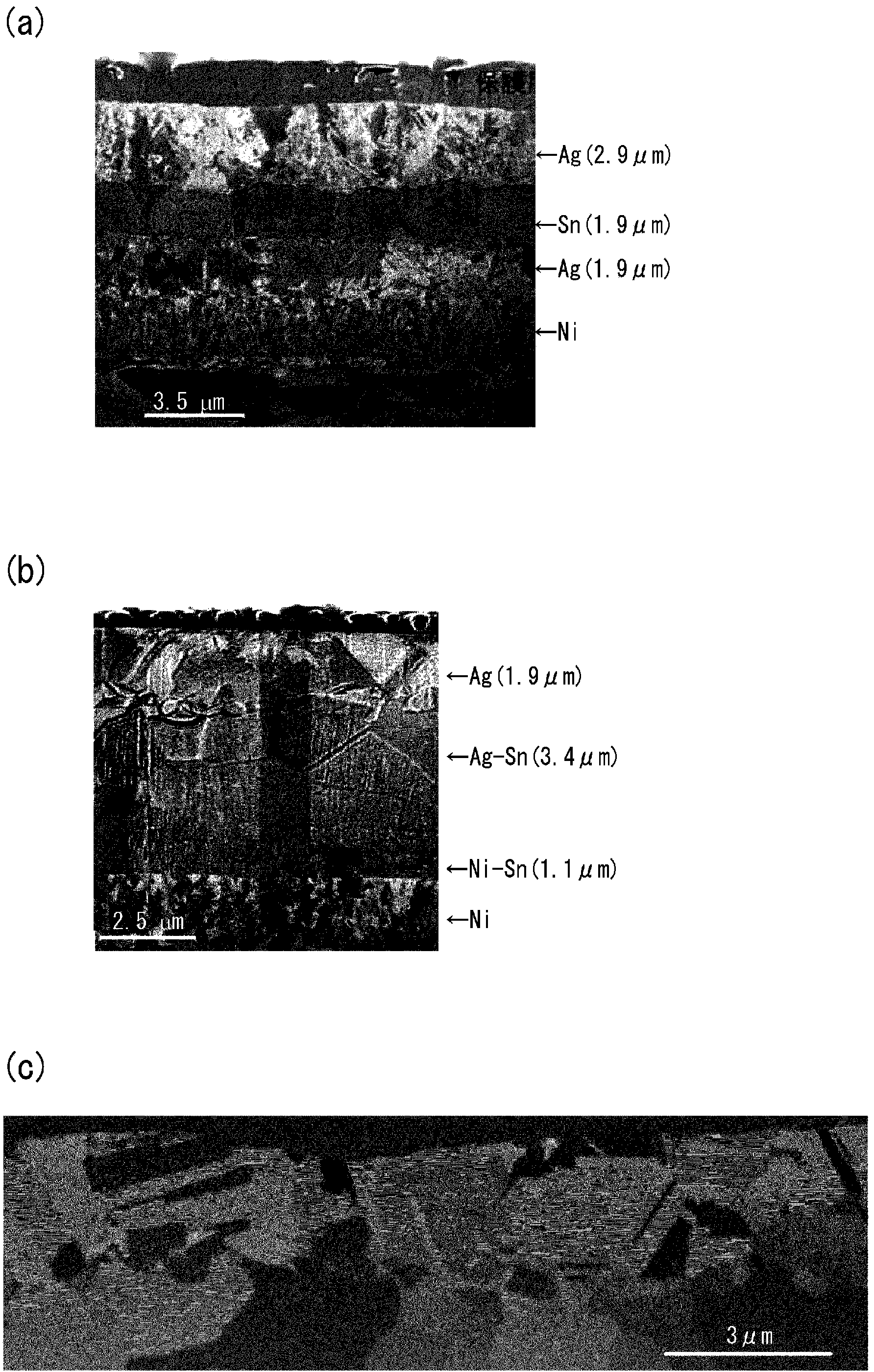

Embodiment 1

[0102] On the surface of the clean copper substrate, a nickel underplating layer with a thickness of 0.5 μm was formed. A soft silver plating layer having a target thickness of 1 μm was formed on the surface of the nickel underplating layer. A tin plating layer having a target thickness of 1 μm was formed on the soft silver plating layer, and a soft silver plating layer having a thickness of 2 μm was further formed on the tin plating layer. This material was heated at 200° C. for 60 minutes in the air. This was made into the plated part of Example 1. The specific formation conditions of the soft silver plating layer and the tin plating layer are as follows.

[0103]

[0104] Use a plating solution with an Ag concentration of 45g / L

[0105] ·Operating temperature: 30℃

[0106] ·Current density: 5ASD (2.5μm / min)

[0107] ・Plating time: 20 to 30 seconds (thickness of the plating layer: 1 μm), 40 to 60 seconds (thickness of the plating layer: 2 μm)

[0108]

[0109] Use ...

Embodiment 2

[0115] In the same manner as in Example 1, a soft silver plating layer with a target thickness of 1 μm, a tin plating layer with a thickness of 1 μm, and a soft silver plating layer with a thickness of 2 μm were sequentially laminated on the surface of a nickel-plated copper substrate in the following order. The coated parts were heated at 290°C for 1 minute.

Embodiment 3

[0117] On the surface of the nickel-plated copper substrate, a plated part in which a soft silver plating layer with a thickness of 1.5 μm, a tin layer with a thickness of 1.0 μm, and a soft silver layer with a thickness of 2.5 μm was sequentially laminated at 290 ° C Heat for 1 minute.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com