Black tea withering-fermenting all-in-one machine and black tea preparation method

An all-in-one machine and withering technology, which is applied in the tea processing before extraction, etc., can solve the problems of a lot of time and labor, the influence of black tea quality, and long waiting time, so as to achieve better taste, save equipment investment, and evenly and fully ferment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

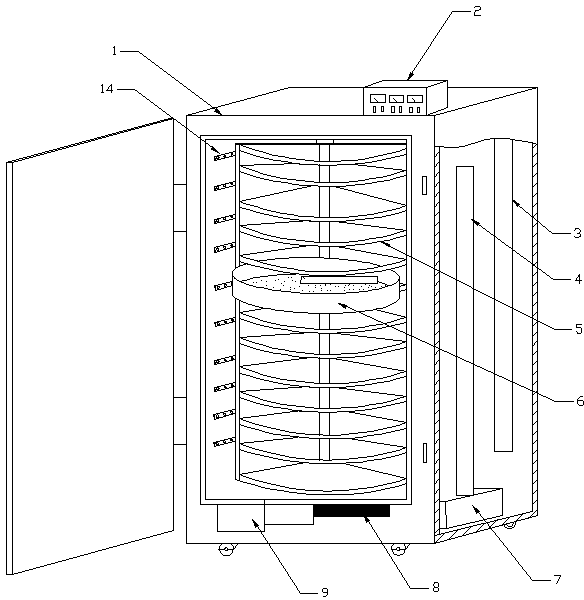

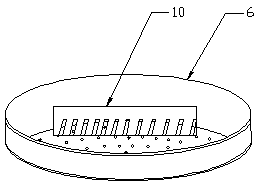

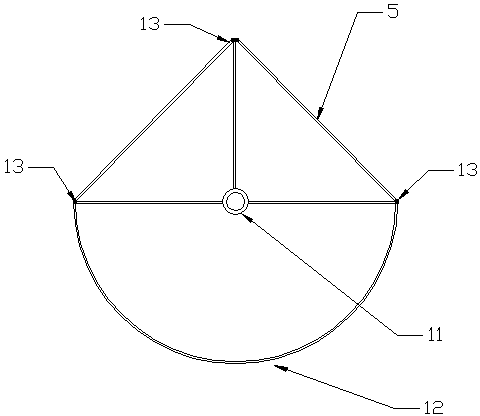

[0025] Specific implementation methods: such as figure 1 , 2 As shown, a black tea withering and fermentation integrated machine includes an airtight casing 1 provided with an opening and closing airtight door. The casing 1 is provided with a rotating bracket 5, and the rotating bracket 5 is a bracket provided with multiple layers of parallel layers. Each layer of support is provided with baskets 6 for holding tea; the outside of the housing 1 is provided with a control box 2, and the control box 2 is provided with an automatic control system electrically connected to the motor, fan, electric heating device and atomization device. Realize switch timing control. A high-strength electromagnet 8 is arranged in the housing 1 at the bottom of the cavity. The basket 6 is provided with a stirring piece 10 made of a magnetically conductive material, which is comb-shaped. The basket 6 is disc-shaped, and the bottom layer of the basket 6 has a mesh-like air-permeable bottom surface....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com