Plant skin whitening preparation and preparation method thereof as well as application of plant skin whitening preparation in skin whitening cosmetics

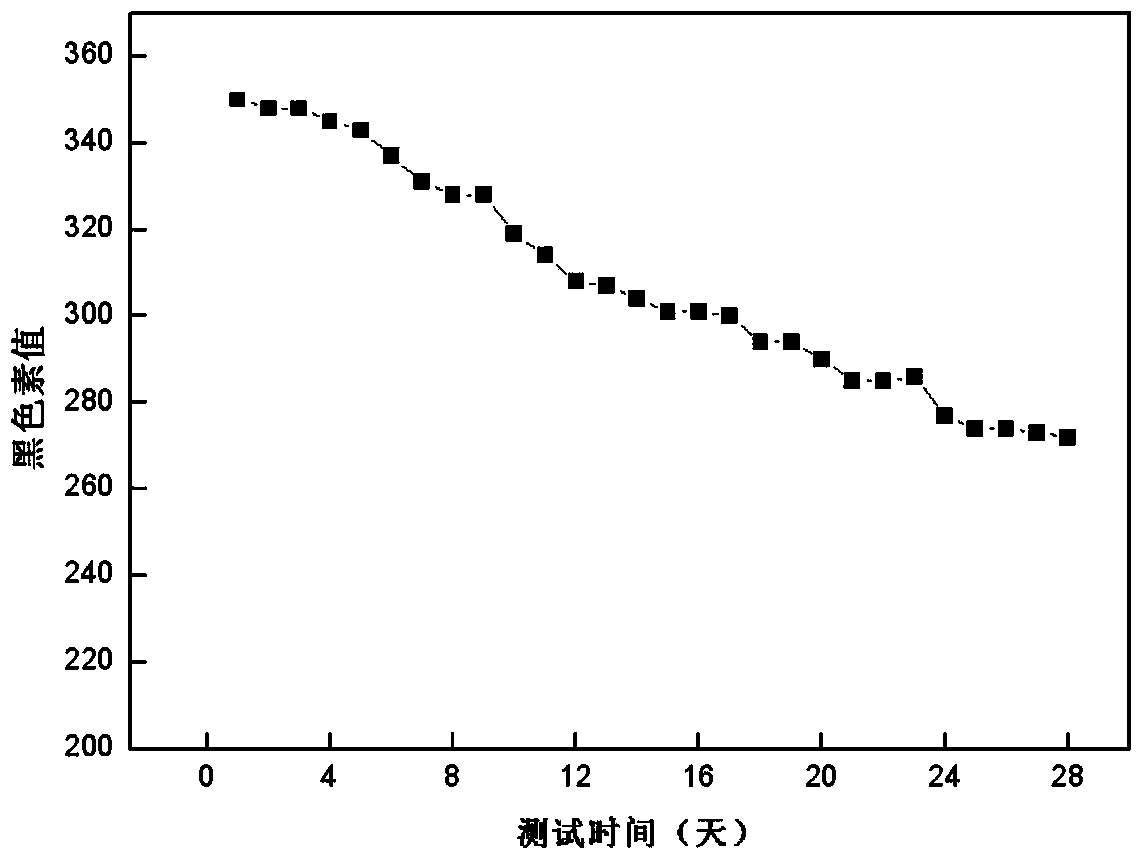

A whitening cosmetic and whitening technology, applied in the field of daily chemicals, can solve the problems of instability, easy to decompose, affect the whitening effect, etc., and achieve the effect of preventing damage, suitable for long-term use, and good whitening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] (1) the water of 96 mass parts and the viscosity-average molecular weight of 4 mass parts are 300,000, the chitosan that deacetylation degree is 90.23% mixes, 200rpm / min stirs, adjust pH value to 2.5 with glacial acetic acid, make chitosan The sugar is completely dissolved to obtain an aqueous solution of chitosan;

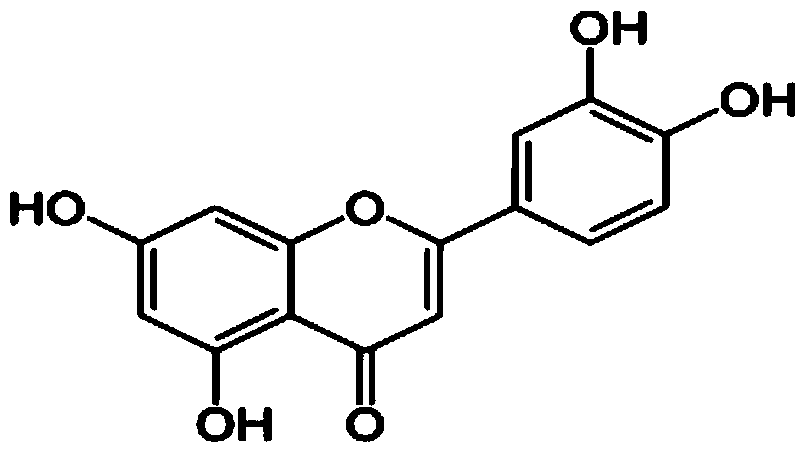

[0082] (2) Mix 1 mass part of luteolin, 2 mass parts of mulberry bark extract, 2 mass parts of licorice flavonoids, 1 mass part of tanshinone, and 8 mass parts of vitamin E acetate, add 5 mass parts of emulsifier, 300rpm / min Stir evenly, homogenize at 3000rpm / min for 3min, add step (1) chitosan aqueous solution to obtain solution I;

[0083] (3) 2 mass parts of carboxymethyl chitosan with a viscosity average molecular weight of 50,000 and a carboxylation degree of 65.0% were added to 98 mass parts of water, stirred and dissolved at 200 rpm / min to obtain solution II;

[0084] (4) With constant temperature at 40°C and stirring at 200 rpm / min, slowly add solu...

Embodiment 2

[0089] (1) the water of 98 mass parts and the viscosity-average molecular weight of 2 mass parts are 500,000, the chitosan that deacetylation degree is 92.60% mixes, 600rpm / min stirs, adjusts pH value to 3.5 with glacial acetic acid, makes chitosan The sugar is completely dissolved to obtain an aqueous solution of chitosan;

[0090] (2) Mix 2 parts by mass of luteolin, 3 parts by mass of mulberry bark extract, 3 parts by mass of licorice flavonoids, 2 parts by mass of tanshinone, and 10 parts by mass of vitamin E acetate, add 8 parts by mass of emulsifier, 800rpm / min Stir evenly, homogenize at 5000rpm / min for 5min, add step (1) chitosan aqueous solution to obtain solution I;

[0091] (3) Add 5 parts by mass of carboxymethyl chitosan with a viscosity average molecular weight of 100,000 and a carboxylation degree of 70.0% to 95 parts by mass of water, stir and dissolve at 600 rpm / min to obtain solution II;

[0092] (4) With constant temperature at 40°C and stirring at 600 rpm / m...

Embodiment 3

[0097] (1) the water of 97 mass parts and the viscosity-average molecular weight of 3 mass parts are 450,000, the chitosan that deacetylation degree is 91.17% mixes, and 300rpm / min stirs, regulates pH value to 3.0 with glacial acetic acid, makes chitosan The sugar is completely dissolved to obtain an aqueous solution of chitosan;

[0098] (2) Mix 1.5 parts by mass of luteolin, 2.5 parts by mass of mulberry bark extract, 2.5 parts by mass of licorice flavonoids, 1.5 parts by mass of tanshinone, and 9 parts by mass of vitamin E acetate, add 7 parts by mass of emulsifier, 600rpm / min Stir evenly, 4000rpm / min homogeneous 4min, add step (1) chitosan aqueous solution, obtain solution I;

[0099] (3) 4 mass parts of carboxymethyl chitosan with a viscosity-average molecular weight of 80,000 and a carboxylation degree of 68.5% were added to 96 mass parts of water, stirred and dissolved at 400 rpm / min to obtain solution II;

[0100] (4) With constant temperature at 55°C and stirring at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com