split flow filter

A filtering device and shunt-type technology, applied in water treatment parameter control, water/sludge/sewage treatment, cleaning methods and appliances, etc., can solve the problem of consuming more water resources, increasing the burden of wastewater treatment equipment, and costing more wastewater treatment and other issues to achieve the effect of ensuring the purity of water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

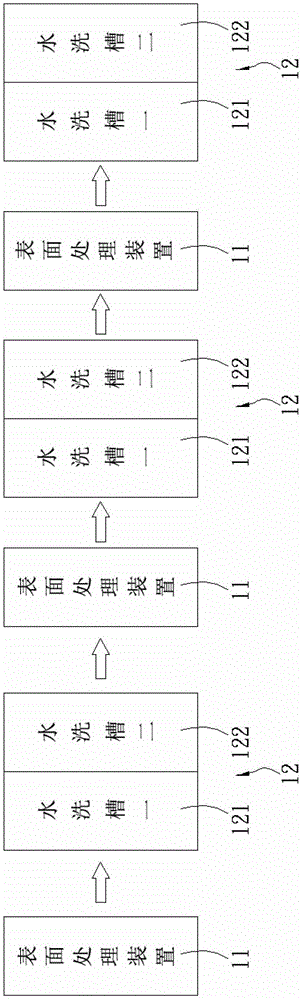

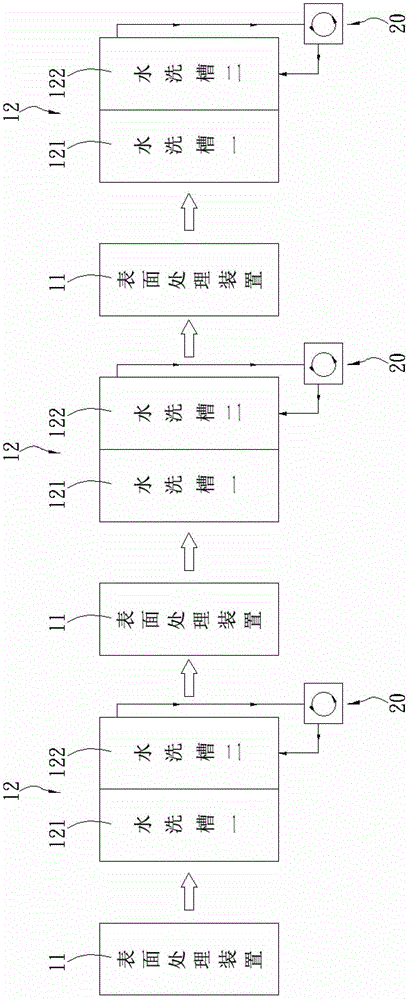

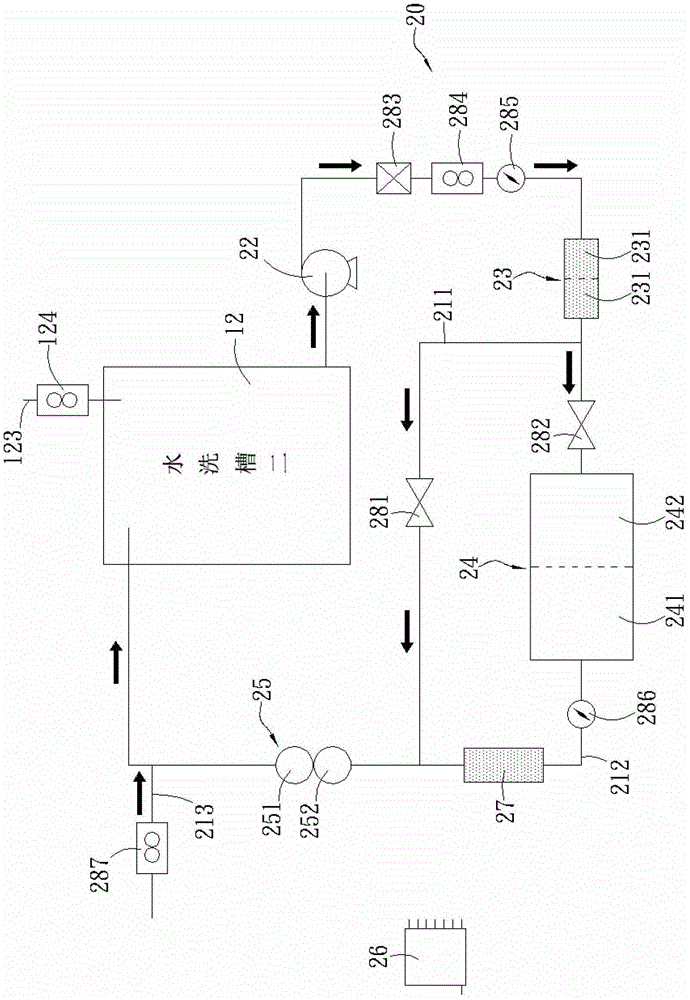

[0051] Such as figure 1 As shown, the split filter device 20 of the present invention can be widely used in the processing process, and is connected with the water washing tank 12 located at the back section of the surface treatment device 11, so as to produce real-time circulation filtering effect on the water in the water washing tank 12, Please cooperate with the reference figure 2 As shown, the split-flow filter device of the present invention basically includes: a set of return water pipelines 211, a booster pump 22, a pre-filter module 23, a group of flow pipelines 212, at least one water quality adjustment module 24. A water quality detection module 25 and a control circuit 26; wherein: the head and tail ends of the set of return water pipelines 211 are connected to the applied washing tank 12, and a middle section of the entire set of return water pipelines 211 is provided with a The first valve element 281 that controls whether the associated pipeline is connected o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com