Improved secondary compression plasma welding torch

A secondary compression and plasma welding technology, applied in plasma welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high processing cost, low arc concentration, weak stiffness, etc., and achieve high arc concentration, High energy efficiency and the effect of increasing welding thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

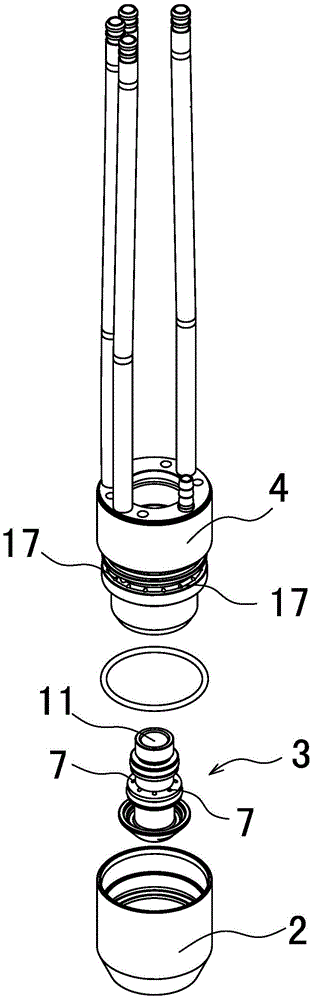

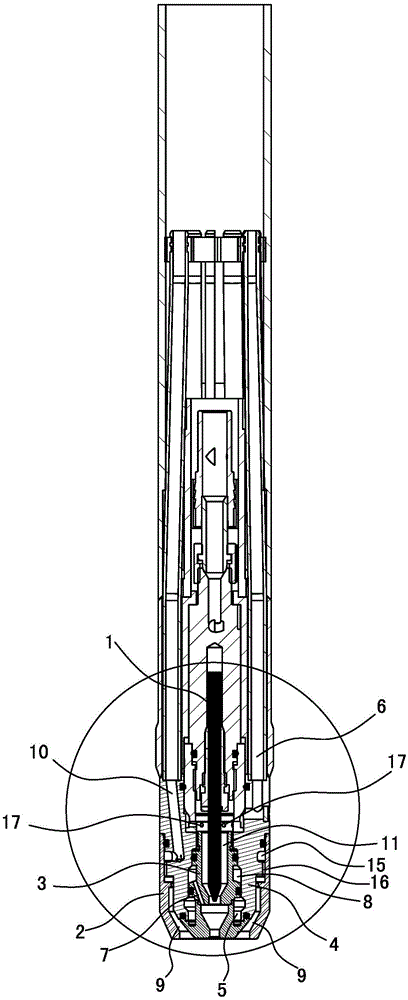

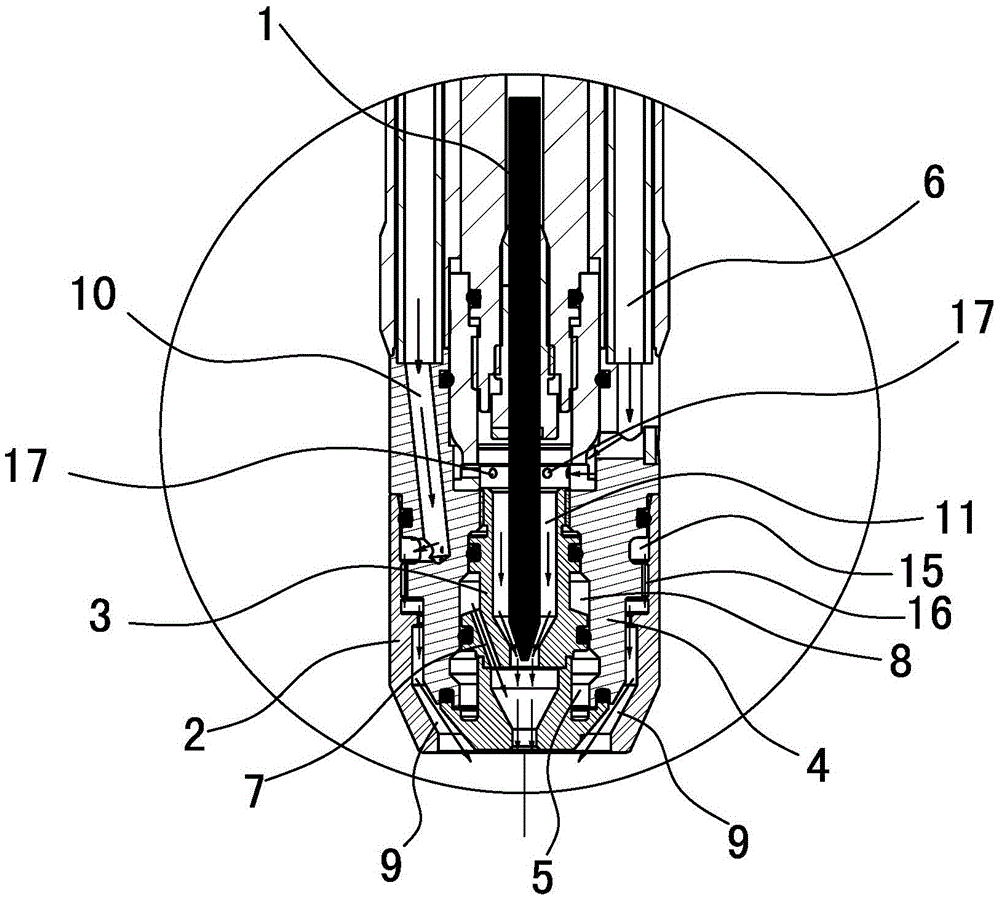

[0035] Embodiment: An improved secondary compression plasma torch

[0036] See attached figure 1 ~ attached Figure 7 As shown, including the gun handle, a tungsten electrode 1 is perforated along the axial direction of the gun handle, and one end of the tungsten electrode 1 is used as a discharge end, and a nozzle and a sheath 2 are arranged at the discharge end, wherein:

[0037] The main body of the nozzle is a cylinder with a hollow structure, and the hollow cavity of the hollow structure is used as an assembly cavity 11. The assembly cavity 11 is arranged along the axial direction of the cylinder, and the two ends of the assembly cavity 11 are opened on the two end faces of the cylinder. , the peripheral wall of the nozzle has a certain thickness.

[0038] The two ends of the assembly chamber 11 are divided into an inlet end and an outlet end along its axial direction, and the discharge end of the tungsten electrode 1 extends into the assembly chamber 11 from the inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com