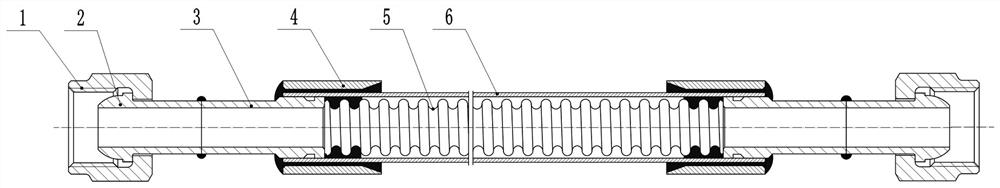

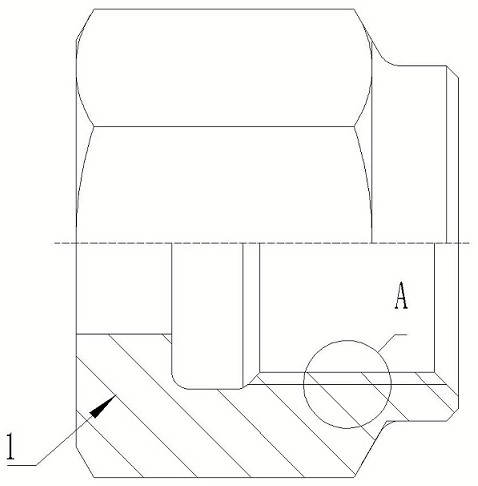

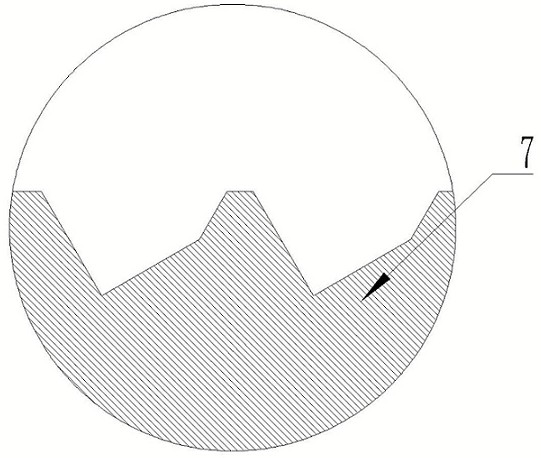

High-pressure metal hose with anti-loose connecting structure and using method thereof

A connection structure and metal hose technology, which is applied in the direction of hoses, hose connection devices, pipes/pipe joints/fittings, etc., can solve the problems of easy leakage and instability at the joints between metal bellows and welding adapters, and achieve Improve the ability to resist pressure and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0041] A method of using a high-pressure metal hose with an anti-loose connection structure. In this embodiment, the high-pressure metal hose with an anti-loose connection structure is mainly used in aero-engines, mainly for installation compensation, vibration reduction and noise reduction , suitable for engine high temperature, vibration environment. In application, the use method includes: according to the pressure of the high-pressure metal hose with a loose connection structure, different layers of metal mesh sleeves 6 are provided, and the number of layers of the metal mesh sleeve 6 is proportional to the pressure of the use environment. Specifically, for a metal hose with a specification of DN20, when the pressure is ≤ 6.4MPa, one layer of metal mesh sleeve 6 is installed; when the pressure range is 6.4MPa ~ 12MPa, two layers of metal mesh sleeve 6 are installed; 12MPa ~ 23MPa, set 3 layers of metal mesh cover 6. In other embodiments of the present invention, the numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com