Woodworking single face planer

A single-sided planer and woodworking technology, applied in the field of plate processing equipment and woodworking single-sided planer, can solve the problems of rough surface of components, unsatisfactory component angles, large wave pitch, etc., to achieve smooth surface, improve planing quality, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

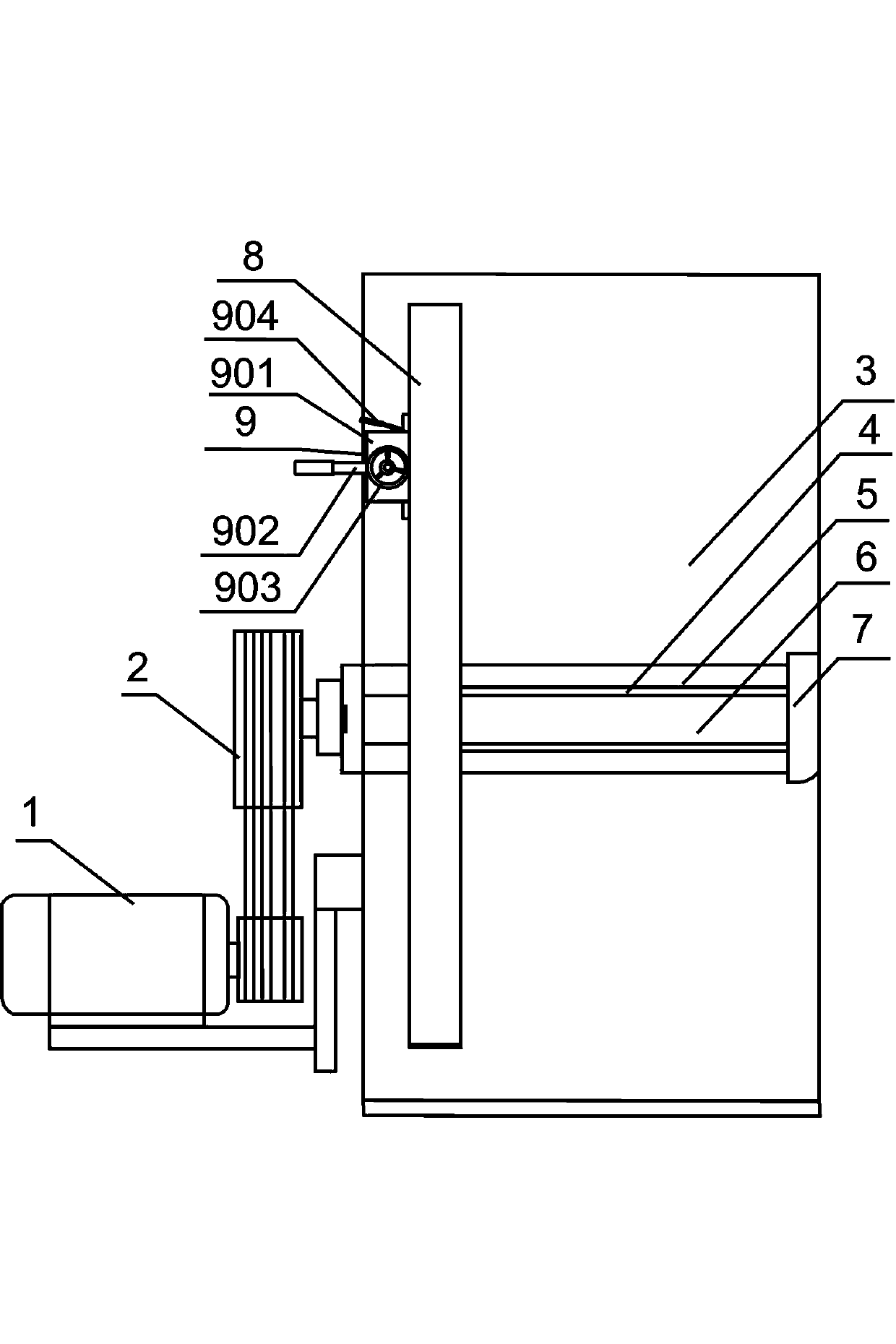

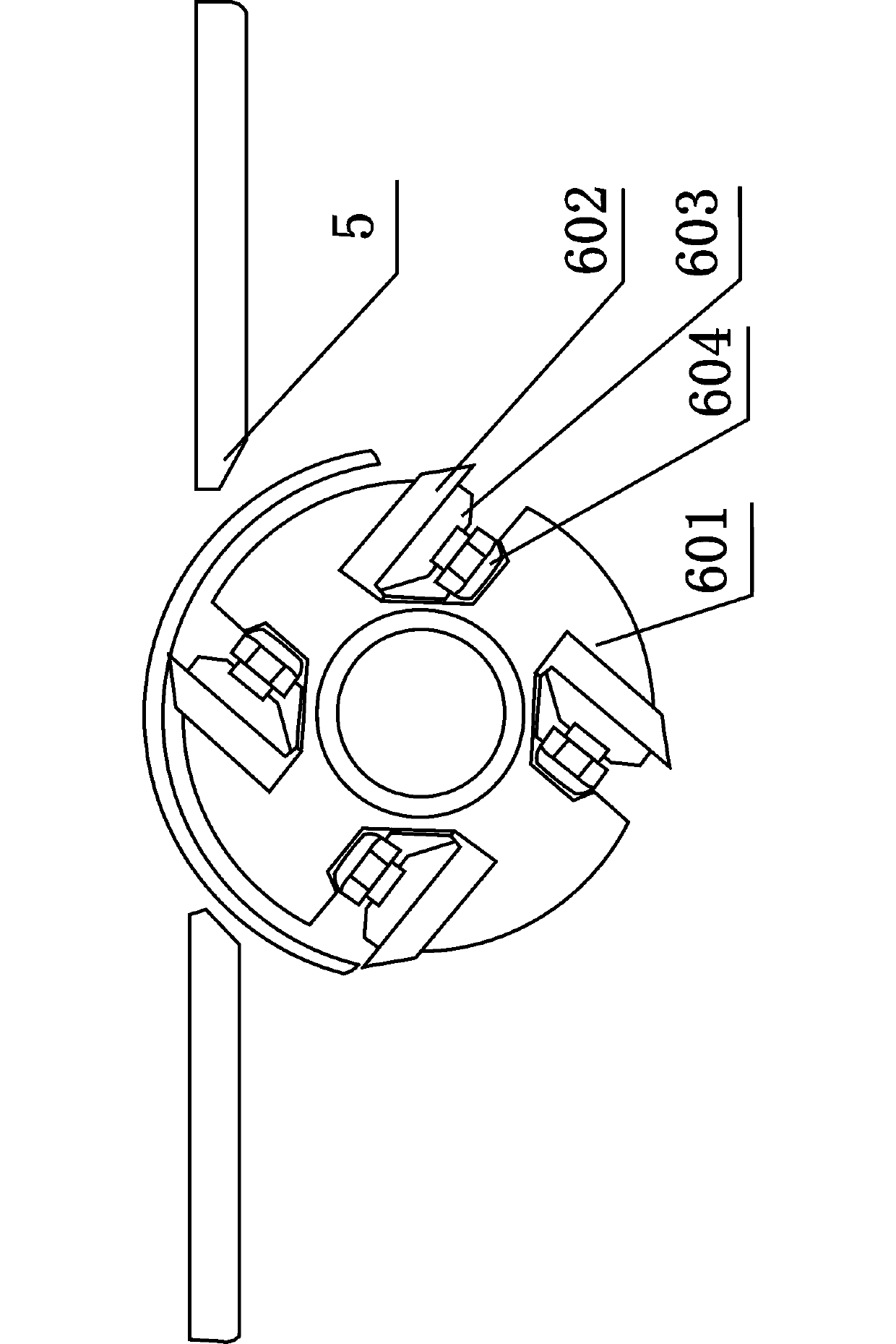

[0029] Such as figure 1 As shown, the present invention includes a drive motor 1, a transmission mechanism 2, a workbench 3, and a workbench lip plate 5, and is characterized in that: it also includes, a cutter groove 4, a planing mechanism 6 for planing wood, a stop Block 7, baffle plate 8, installation mechanism 9 for installing the baffle plate, there is a tool slot 4 in the middle position of the workbench 3, the planing mechanism 6 is installed in the tool slot 4, and the transmission mechanism 2 is connected by transmission The drive motor 1 and the planing mechanism 6, the stopper 7 is fixed on the workbench 3 at the end of the tool groove 4 away from the transmission mechanism, and pressed on the workbench lip 5, the baffle 8 is installed on the installation mechanism 9 , the mounting mechanism 9 is fixed on the workbench 3 .

[0030] The specific data of the mechanism components of the present invention are: one workbench, the specific size (mm) (length*width) is 170...

Embodiment 2

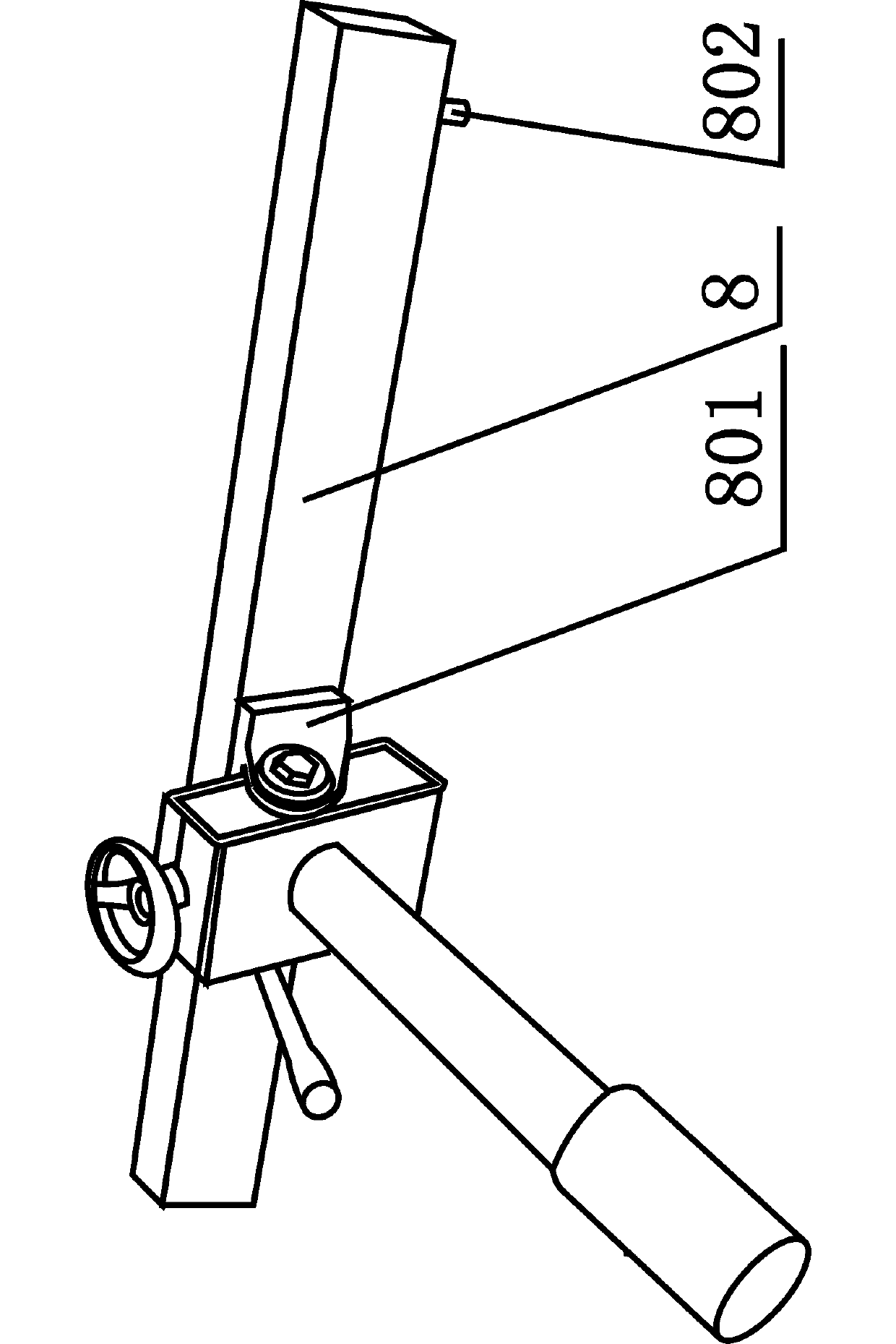

[0032] In order to ensure that the baffle is fastened on the workbench, and at the same time ensure that the plane where the baffle is located remains stable and does not cause deflection, this embodiment is further improved on the basis of Embodiment 1. The baffle 8 of this embodiment includes There are two baffle mounting pieces 801 and a columnar protrusion 802 , the columnar protrusion 802 is connected under one end of the baffle 8 , and the baffle installation piece 801 is connected to the middle part of the baffle 8 .

Embodiment 3

[0034] In order to ensure that the baffle can work for a long time under dynamic load environmental conditions, with stable performance and long service life, this embodiment is further improved on the basis of any one of embodiments 1 to 2. The baffle of this embodiment The material of plate 8 is any one of silicon-manganese spring steel, silicon-chromium spring steel, chromium-manganese spring steel, chrome-vanadium spring steel, and tungsten-chrome-vanadium spring steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com