Ardealite producing method

A production method and technology of phosphogypsum, applied in the field of phosphoric acid, can solve problems such as increase of phosphogypsum, land occupation, secondary pollution of the environment and water body, etc., and achieve the effect of easy operation and great practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of phosphogypsum production method comprises the steps:

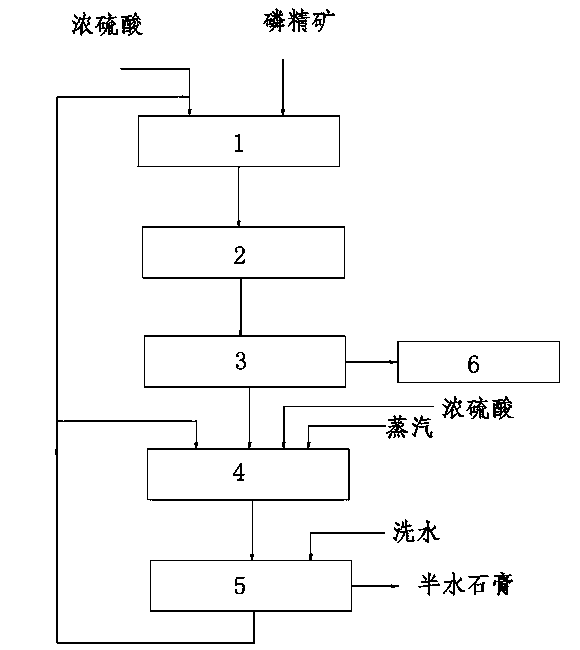

[0019] (1) Mix the concentrated sulfuric acid with the process water used in the production of wet-process phosphoric acid and then enter the dihydrate crystallization tank 1 to react with the phosphorous concentrate; control the solid content between 5% and 35%.

[0020] (2) The reacted slurry enters the aging tank 2 for crystallization, and the crystallized slurry enters the filter equipment A3 for separation. The separated liquid is dilute acid, which enters the dilute acid storage tank 6; the filtered gypsum enters the semi-water crystallization tank 4 carry out recrystallization;

[0021] (3) When the filtered gypsum enters the semi-hydrate crystallization tank 4, steam is passed into the semi-hydrate crystallization tank 4, and at the same time, concentrated sulfuric acid is added to control the solid content between 20% and 40%, and at the same time, the semi-hydrate crystallization tank 4. The tem...

Embodiment 2

[0025] A method for producing phosphogypsum, the method comprising the steps of:

[0026] (1) Mix the concentrated sulfuric acid with the liquid from the filter device B5 and then enter the dihydrate crystallization tank 1 to react with the phosphorous concentrate; control the solid content between 25% and 35%.

[0027] (2) The reacted slurry enters the aging tank 2 for crystallization, and the crystallized slurry enters the filter equipment A3 for separation. The separated liquid is dilute acid, which enters the dilute acid storage tank 6; the filtered gypsum enters the semi-water crystallization tank 4 carry out recrystallization;

[0028] (3) When the filtered gypsum enters the semi-hydrate crystallization tank 4, steam is passed into the semi-hydrate crystallization tank 4, and at the same time, concentrated sulfuric acid is added to control the solid content between 20% and 40%, and at the same time, the semi-hydrate crystallization tank 4. The temperature is controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com