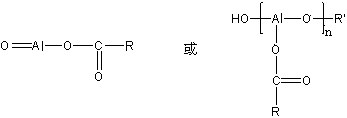

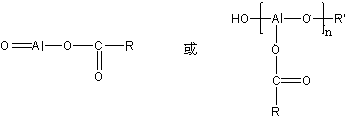

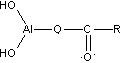

Preparation process for preparing mineral oil-based aluminum-oxygen polymer by using dihydroxyl aluminum carboxylate intermediate

A technology of dihydroxycarboxylic acid and aluminum hydroxycarboxylate, which is applied in the field of preparation of mineral oil-based aluminum-oxygen polymers, can solve problems such as difficult control of alumina and block particles, difficult reaction, and consumption of organic acids , to achieve the effects of easy control of reaction conditions, stable performance and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 204g of aluminum isopropoxide to 200g of isopropanol, stir and heat to 60°C, add 144g of isooctanoic acid, stir for 1 hour; add 45g of water, carry out hydrolysis reaction, keep warm at 60°C for 2 hours; filter to obtain a white precipitate , and dried to obtain 203 g (99.5% yield) of aluminum dihydroxyisooctoate powder.

[0027] Take 102g of aluminum isopropoxide and add it to 100g of mineral oil, heat to 85°C, and start to add 72g of isooctanoic acid dropwise; after dropping isocaprylic acid, heat up to 150°C; add 102g of aluminum dihydroxyisooctanoate powder, and keep warm at 140°C React for 3 hours until the solution becomes clear; cool to obtain 285 g grass-green viscous substance with an aluminum content of 9.4% and a yield of 99.6%.

Embodiment 2

[0029] Add 204g of aluminum isopropoxide to 200g of isopropanol, stir and heat to 70°C, add 284g of isooctanoic acid, stir and react for 1 hour; add 50g of water, carry out hydrolysis reaction, keep the reaction at 65°C for 2 hours; filter to obtain white precipitate , and dried to obtain 342g (99.4% yield) of aluminum dihydroxystearate powder.

[0030] Take 102g of aluminum isopropoxide and add it to 100g of mineral oil, heat to 90°C, start to add 72g of isooctanoic acid dropwise; after adding isocaprylic acid dropwise, heat up to 140°C; add 102g of aluminum dihydroxyisooctanoate powder, and keep warm at 160°C React for 8 hours until the solution is clear; cool to obtain 285 g grass green viscous liquid, the aluminum content is 9.4%, and the yield is 99.6%.

Embodiment 3

[0032] Add 204g of aluminum isopropoxide to 200g of isopropanol, stir and heat to 70°C, add 144g of isooctanoic acid, stir for 1 hour; add 45g of water, carry out hydrolysis reaction, keep the reaction at 70°C for 2 hours; filter to obtain a white precipitate , and dried to obtain 203 g (99.5% yield) of aluminum dihydroxyisooctoate powder.

[0033] Take 102g of aluminum isopropoxide and add it to 100g of mineral oil, heat to 85°C, start to add 72g of isooctanoic acid dropwise; after adding isocaprylic acid dropwise, heat up to 180°C; add 102g of aluminum dihydroxyisooctanoate powder, and keep warm at 170°C React for 2 hours until the solution is clear; cool to obtain 285 g grass green viscous liquid, the aluminum content is 9.4%, and the yield is 99.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com