Method for extracting linseed oil by cold pressing with salt-water wetting

A technology of linseed oil and linseed oil, which is applied in the field of cold pressing to provide linseed oil and salt water wet cold pressing to extract linseed oil, can solve the problems of low oil yield of linseed oil, achieve easy industrial production, mild reaction conditions, reduce The effect of the amount of organic solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) Select 100 catties of plump flaxseed, add 8 catties of NaCl aqueous solution (concentration is 20g / L) after natural drying;

[0015] (2) Put the mixed linseed into a twin-screw oil press for pressing. The control screw speed is 40r / min, the pressing temperature is 20°C, and the feed rate is 100kg / h;

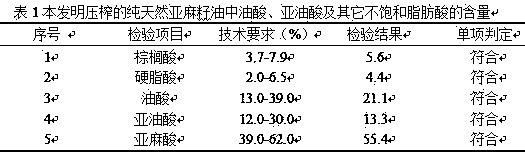

[0016] (3) The obtained crude oil is separated by a high-speed centrifuge, the centrifuge temperature is controlled at 20°C, and the rotation speed is 15,000 rpm. Obtaining pure natural linseed seed oil is 35.20 jin. The oil yield was 35.20%, and the various indexes of the oil products are shown in Table 1.

Embodiment 2

[0018] (1) Select 100 catties of plump flaxseed, add 15 catties of NaCl aqueous solution (concentration is 5g / L) after natural drying;

[0019] (2) Put the mixed linseed into a twin-screw oil press for pressing. Control the screw speed to be 50r / min, the pressing temperature to be 50°C, and the feed rate to be 120kg / h;

[0020] (3) The obtained crude oil is separated by a high-speed centrifuge, the centrifuge temperature is controlled at 15°C, and the rotation speed is 20,000 rpm. Obtaining pure natural linseed oil is 34.90 jin. The oil yield was 34.90%, and the various indexes of the oil products are shown in Table 1.

Embodiment 3

[0022] (1) Select 100 catties of plump flaxseed, add 10 catties of NaCl aqueous solution (concentration is 15g / L) after natural drying;

[0023] (2) Put the mixed linseed into a twin-screw oil press for pressing. Control the screw speed to 45r / min, the pressing temperature to 25°C, and the feed rate to 110kg / h;

[0024] (3) The obtained crude oil is separated by a high-speed centrifuge, the centrifuge temperature is controlled at 25°C, and the rotation speed is 15,000 rpm. Obtaining pure natural linseed seed oil is 36.50 jin. The oil yield was 36.50%, and the various indexes of the oil products are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com