A rapid test mechanism and test method for the centering of a lift-type evaporator

A testing mechanism and evaporator technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of easy deviation of test points from the center line, poor accuracy, inconvenient operation, etc., to achieve the effect of convenient testing, guaranteeing effectiveness and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

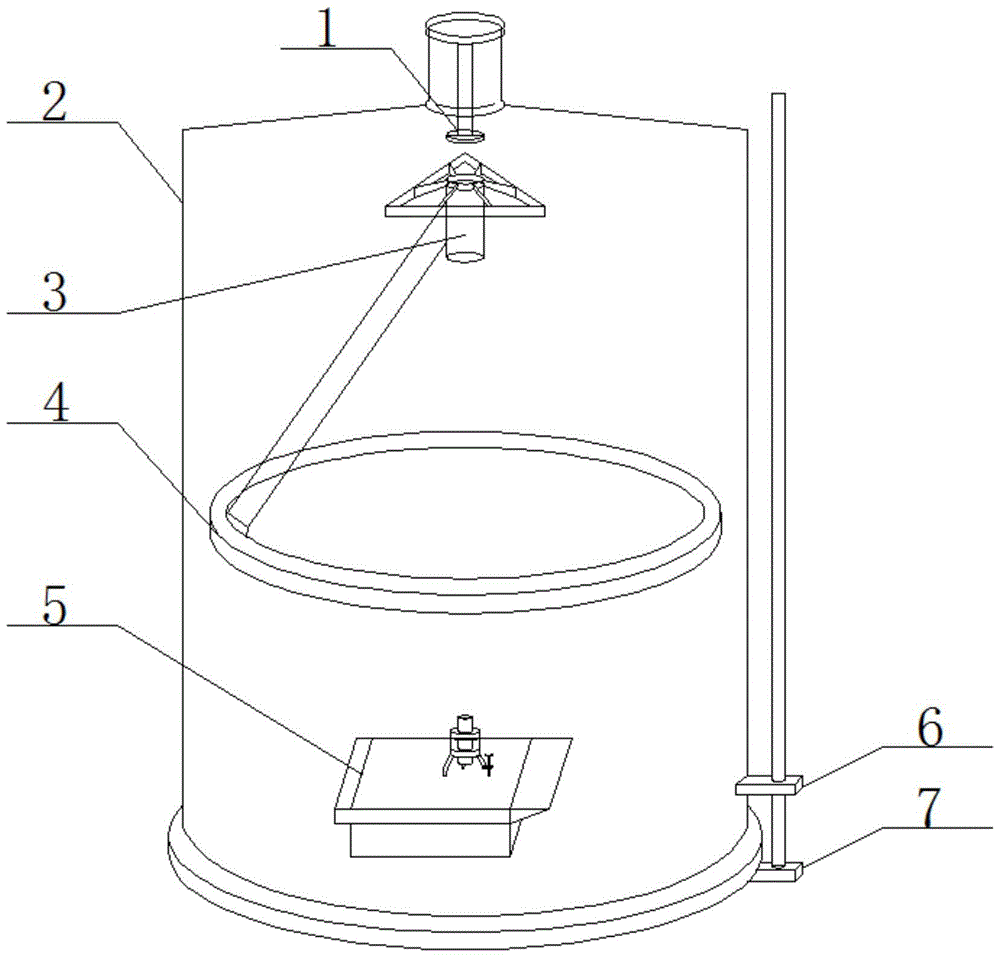

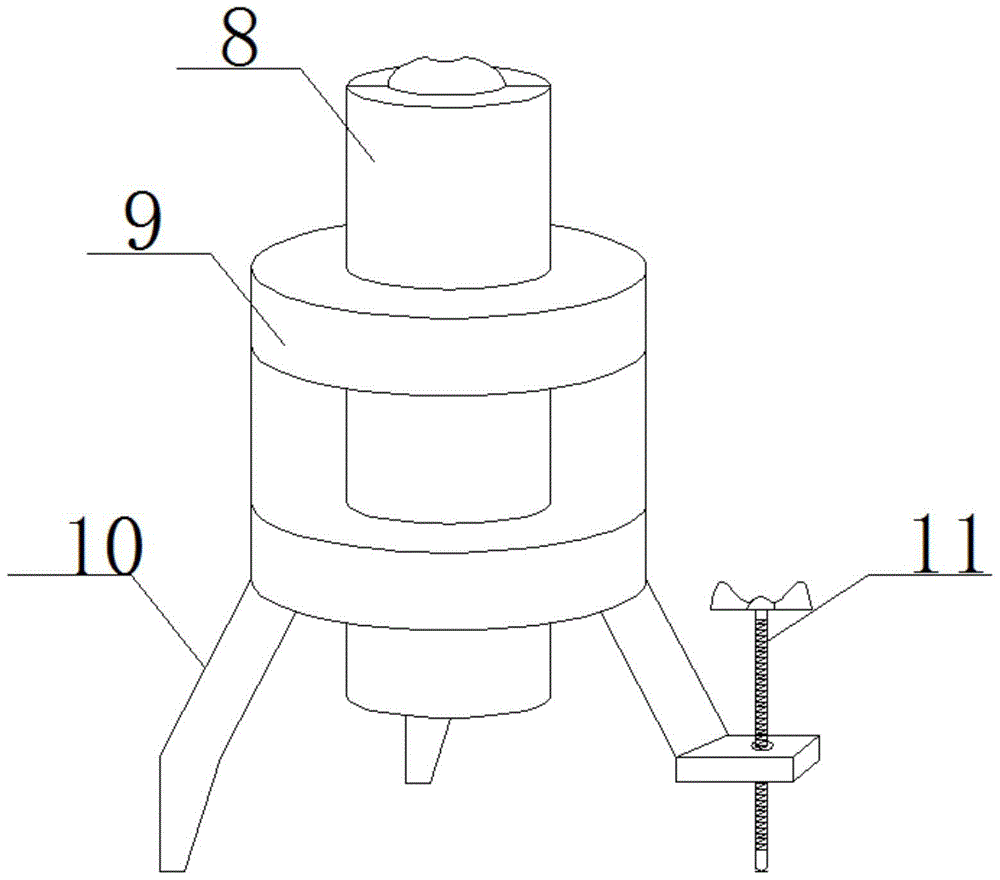

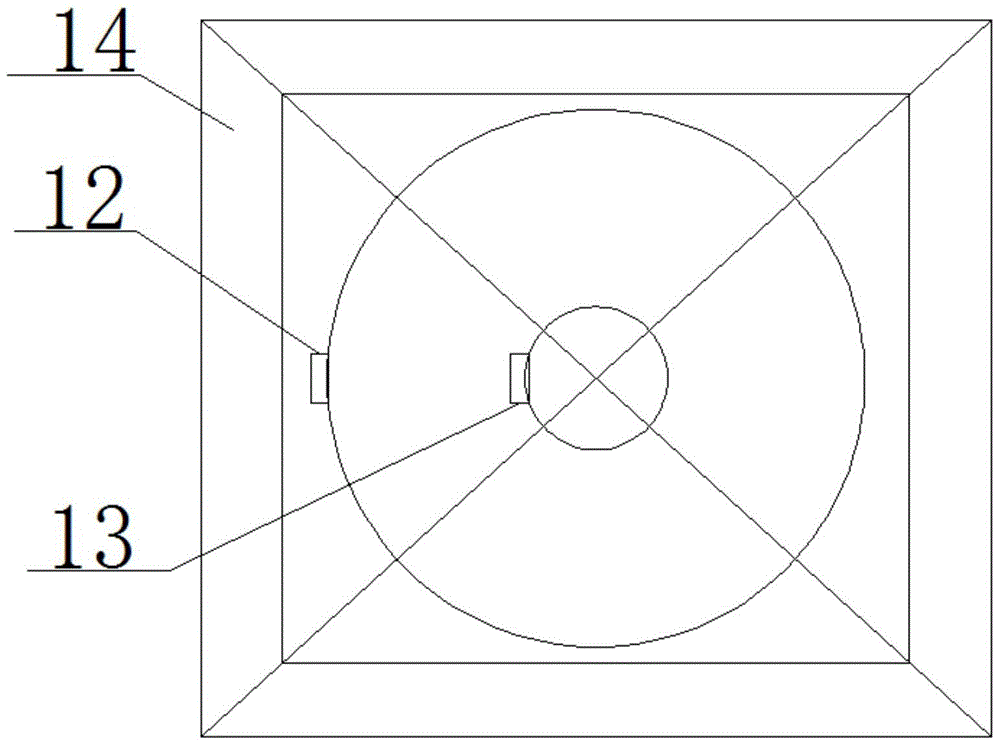

[0035] A rapid test mechanism for the centering of a lift-type evaporation machine, such as figure 1 , including a thickness measuring cover 1, a bell jar 2, a tripod 3, a fixed tripod seat 4, an electron gun 5, a transparent offset plate 14 and an emission point light source adjustment device. The bell jar 2 is made of transparent glass, the thickness measuring cover 1 is located on the top of the bell jar 2, and the thickness measuring cover 1 is built with a sensor probe for measuring thickness. The middle part of the bell jar 2 is equipped with a fixed tripod seat 4, and the tripod 3 is installed on the top of the fixed tripod seat 4, and the bottom of the fixed tripod seat 4 is a ring, and the ring is connected to the tripod 3 by a support, and the tripod 3 There is a hole in the center, an electron gun 5 is arranged at the bottom of the bell jar 2, and a crucible is placed in the electron gun 5 . The outer side of the bell jar 2 is provided with a guide rod 7, the botto...

Embodiment 2

[0046] Embodiment 2 is basically the same as Embodiment 1, the difference is that, in step e, the bell jar 2 is lifted and lowered 3 times to test whether the position of the point light source is in the same position as in step e. At the center position, the position of the point light source does not fall on the center position. Repeat steps (a)-(d) to successfully make the position of the point light source always fall on the center position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com