Optical efficiency detection method for reflecting surface of primary mirror of large-aperture photoelectric telescope

A photoelectric telescope and optical efficiency technology, which is applied in the direction of testing optical performance, etc., can solve the problems of inability to detect the reflection surface efficiency of the main mirror of a large-aperture photoelectric telescope online, and achieve the effect of simple, low cost and fast detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

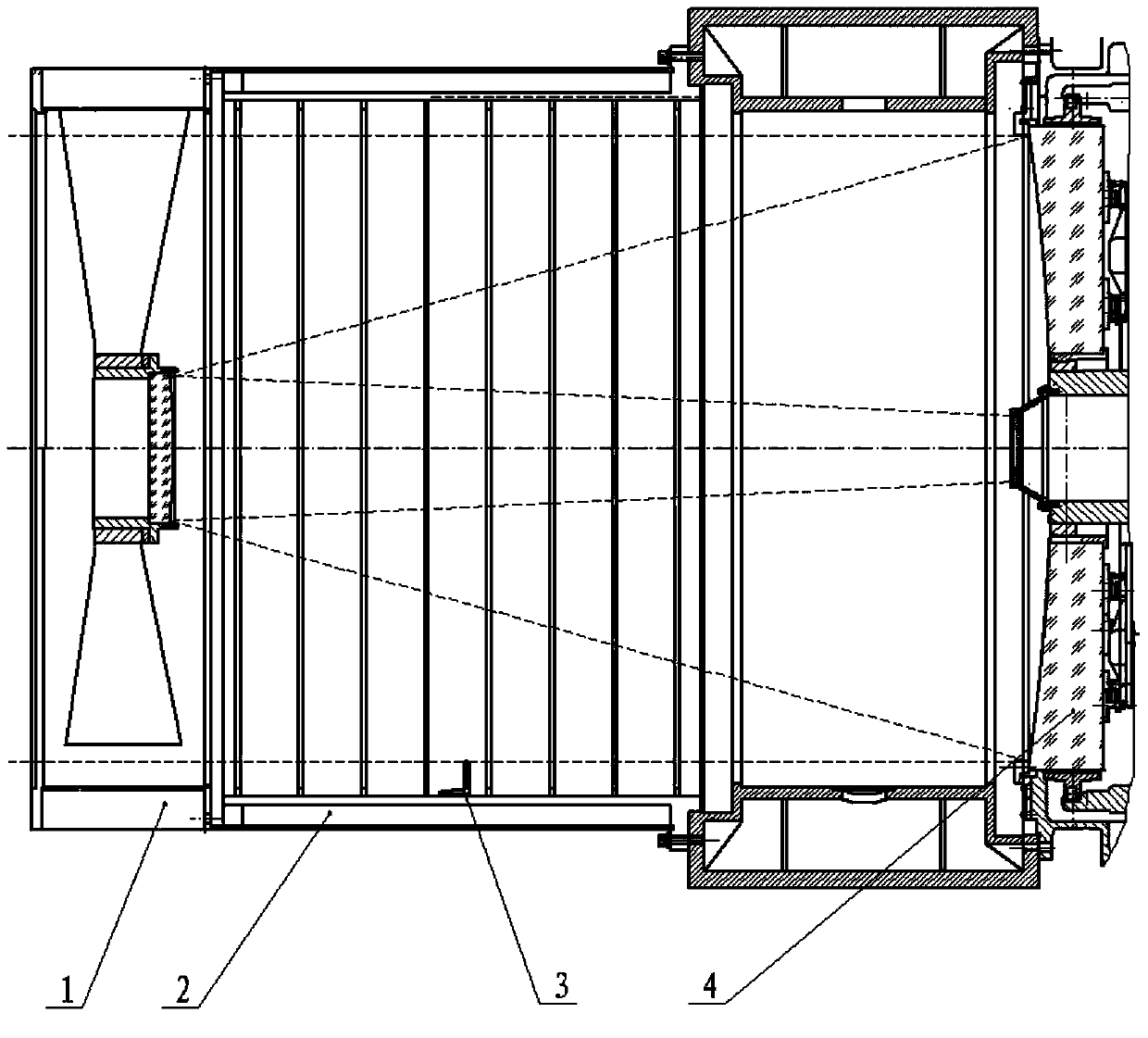

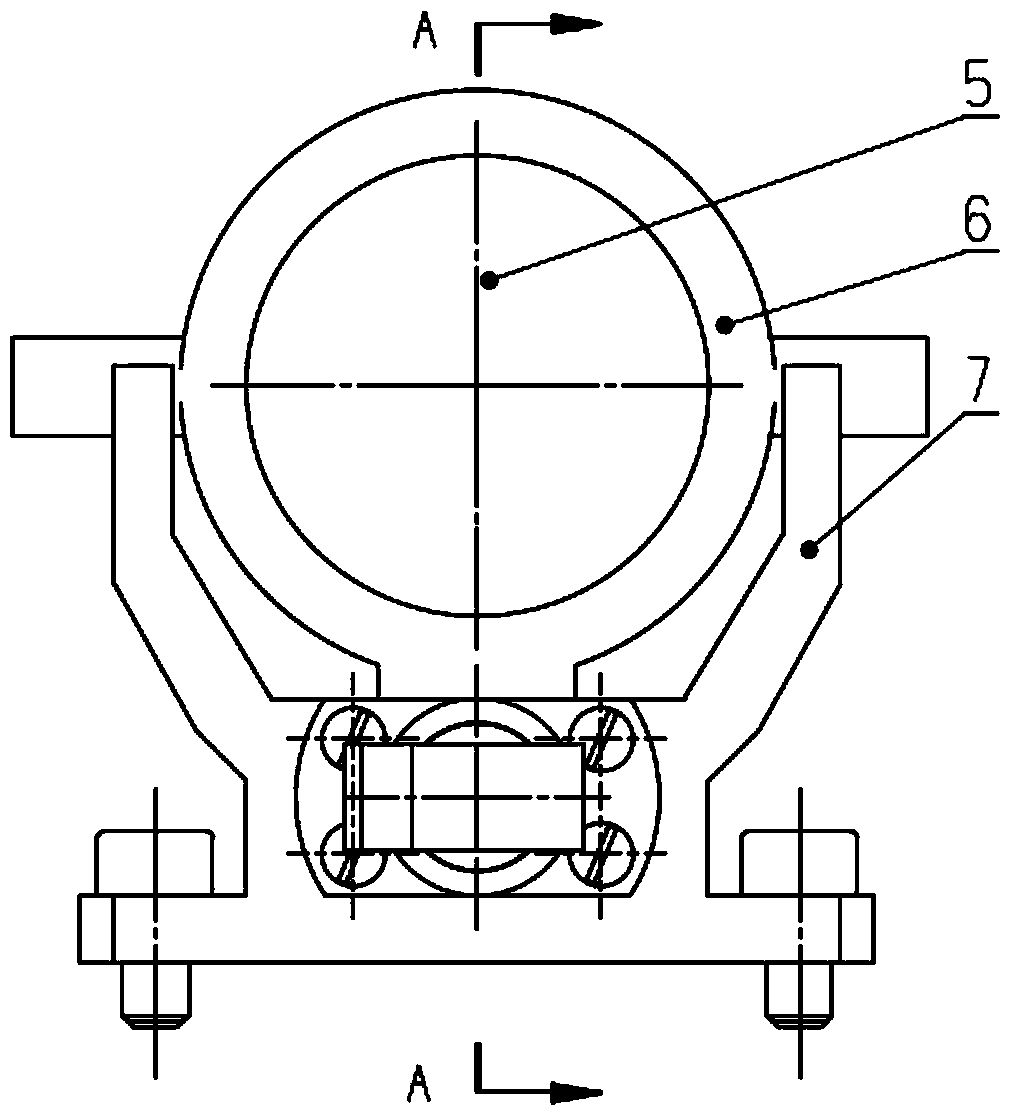

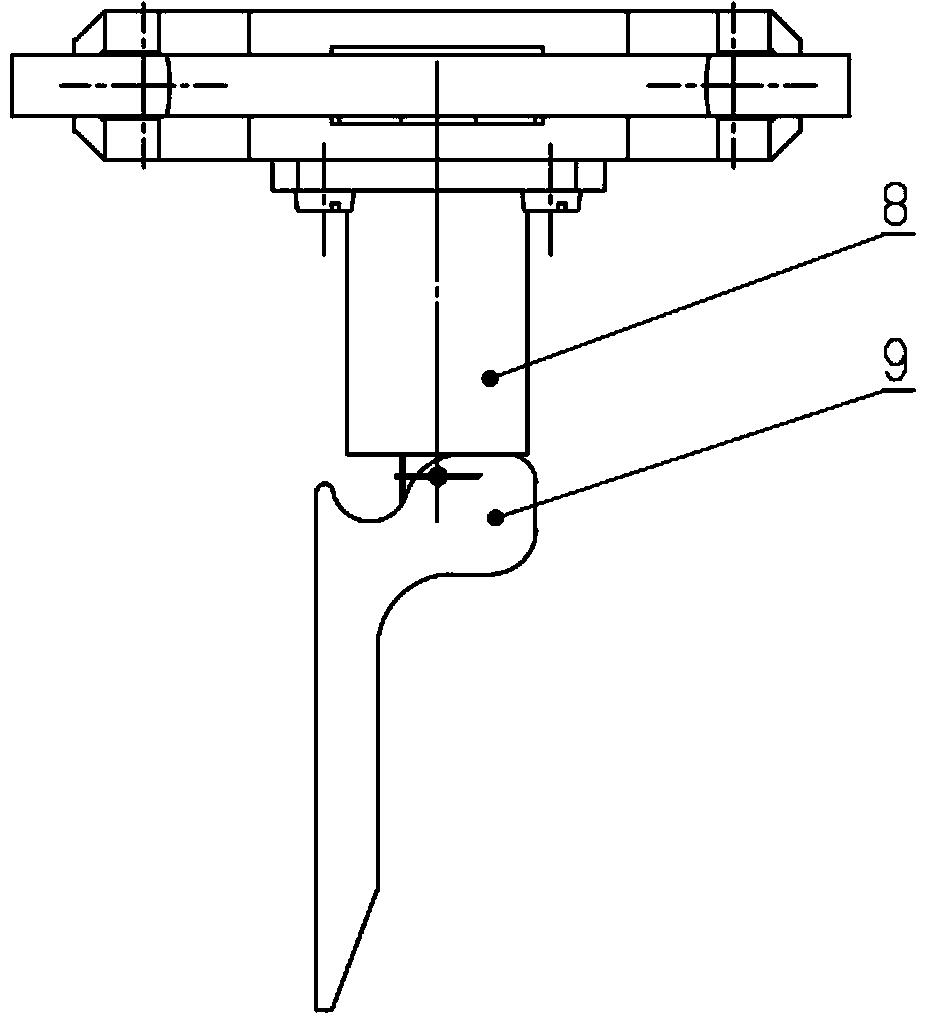

[0021] See attached figure 1 , a kind of optical efficiency detection method of the primary mirror reflection surface of a large-diameter photoelectric telescope of the present invention adopts the following technical scheme: the secondary mirror chamber 1 is installed on the main mirror barrel, and a set of mirror chamber 2 is installed on the inner wall of the main mirror chamber of the main mirror barrel through a fixing device The monitoring test lens assembly 3 that can be disassembled and detected quickly, the monitoring test lens assembly 3 includes a mirror frame 6 and a test lens 5; 4. The reflective surface is in the same use environment; the test lens 5 is made of the same material as the main mirror 4, and the test lens 5 and the main mirror 4 are coated simultaneously, and the film system of the coating layer on the surface of the test lens ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com