Wind-generator blade defect damage inspection method and inspection system based on unmanned helicopter

A technology of unmanned helicopters and inspection methods, which is applied in the direction of material defect testing, optical testing of flaws/defects, and analysis of solids using sound waves/ultrasonic waves/infrasonic waves, etc. Hidden dangers, difficult high-density inspections, etc., to avoid the expansion of defects and damage, avoid the influence of adverse factors, and increase the inspection density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings.

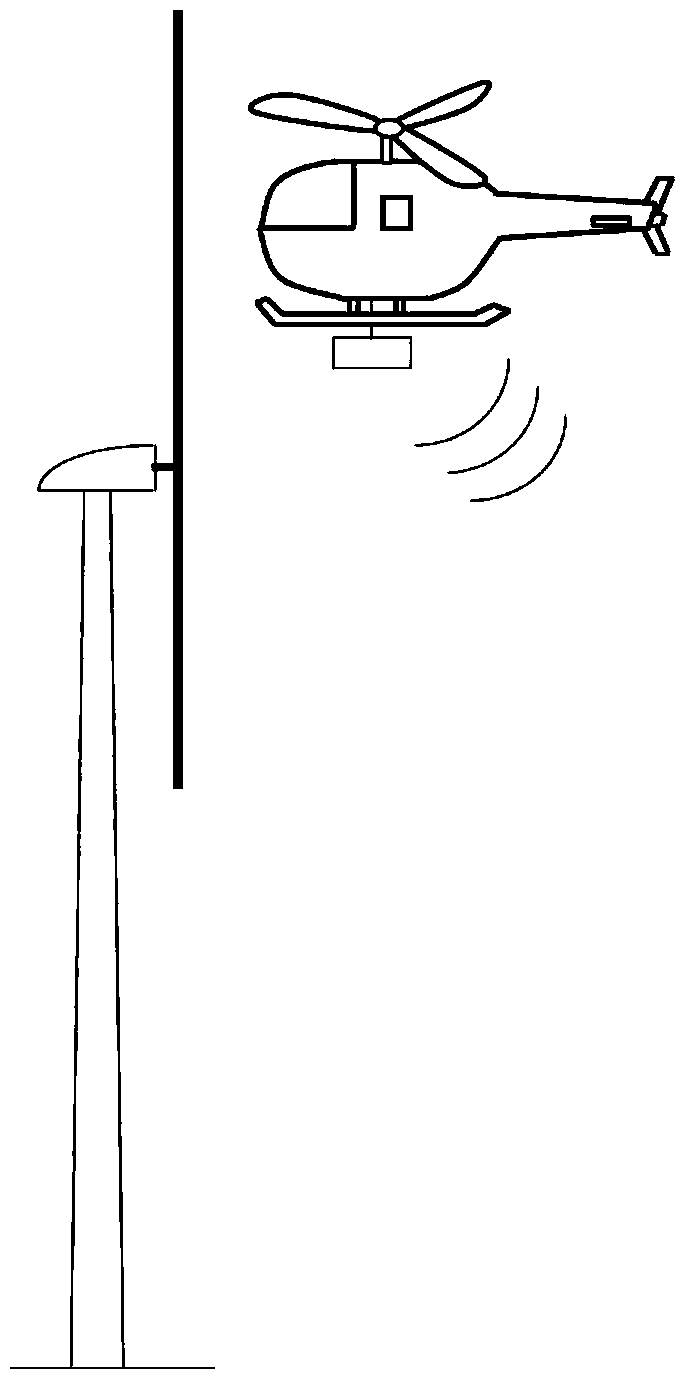

[0024] Such as figure 1 As shown in the figure, the blade is installed on the wind power tower, and its surface is prone to surface erosion, partial shedding, trachoma, surface cracking, and surface freezing under the action of sandstorms, corrosive gases, lightning strikes, and large-scale temperature differences. Defects or damages, these defects or damages have the characteristics of small size and difficult to be found in the early stage. In the process of continuing operation, these defects and damages will continue to expand, which will seriously affect the safety of the fan.

[0025] A method for close inspection of wind turbine blade damage, comprising the following steps:

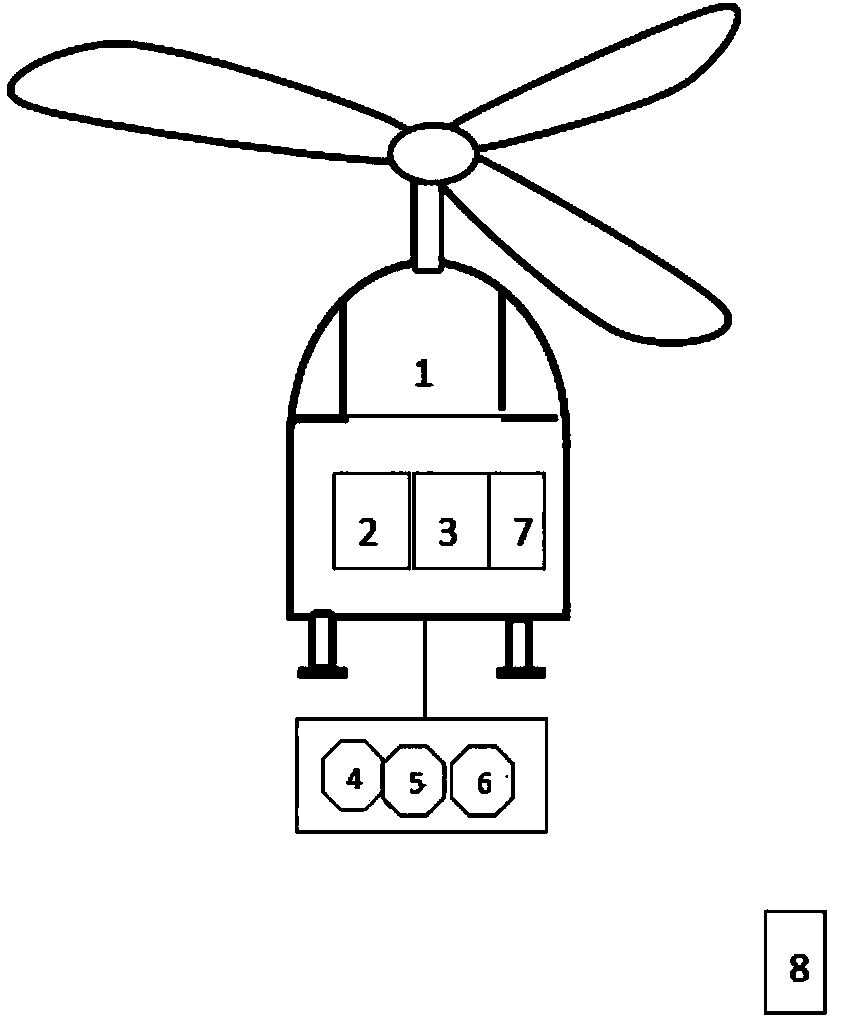

[0026] Step (1), manipulating the unmanned helicopter installed with miniature visible light image collector, miniature infrared thermal imager, miniature sound sensor, distance sensor an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com