End sealing method for low-voltage foil type coil of dry type transformer

A technology of dry-type transformers and low-voltage coils, applied in the field of transformers, can solve problems affecting the performance and appearance quality of transformers, shorten the service life of transformers, etc., and achieve the effect of improving appearance quality and electrical performance, clear edges and corners, and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

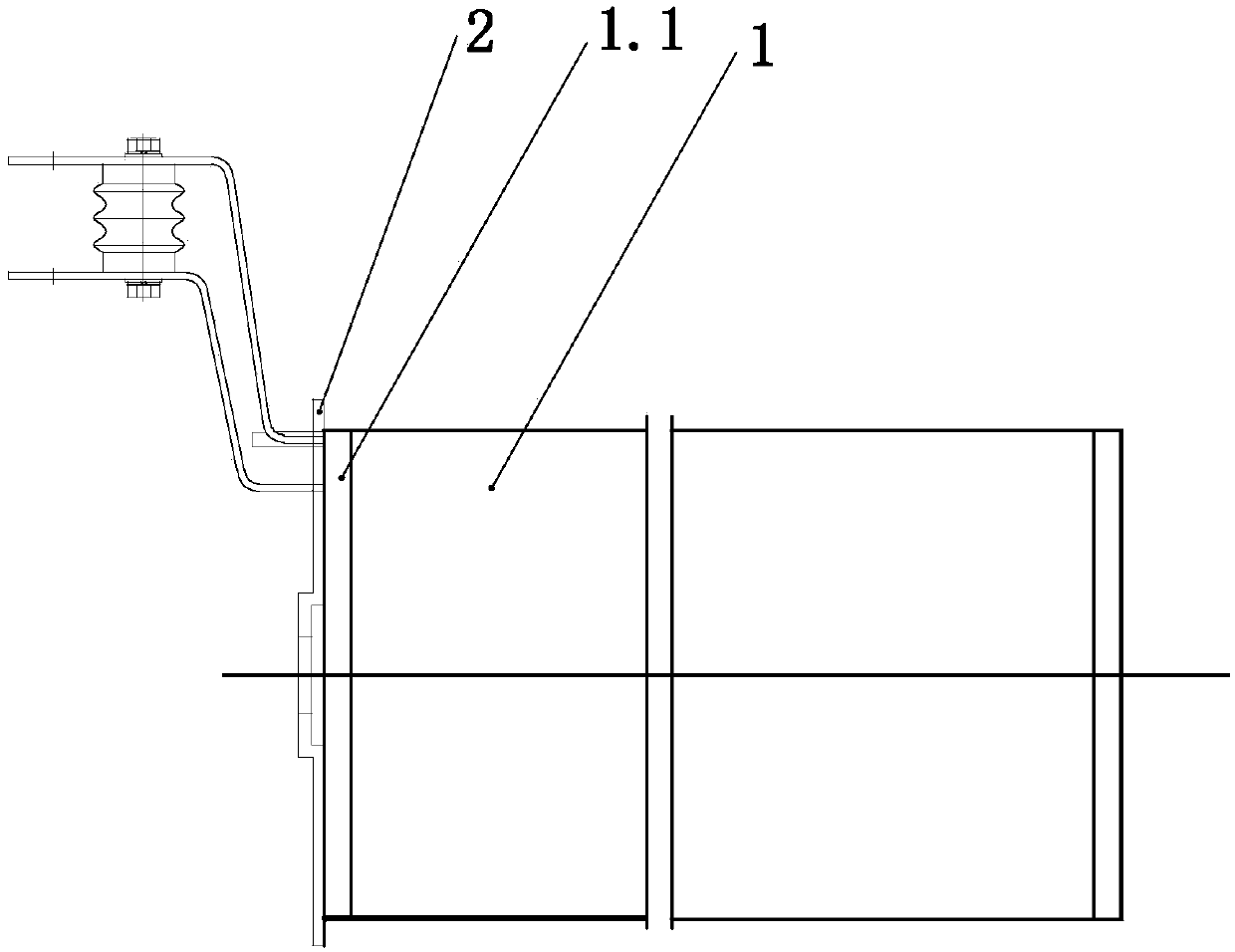

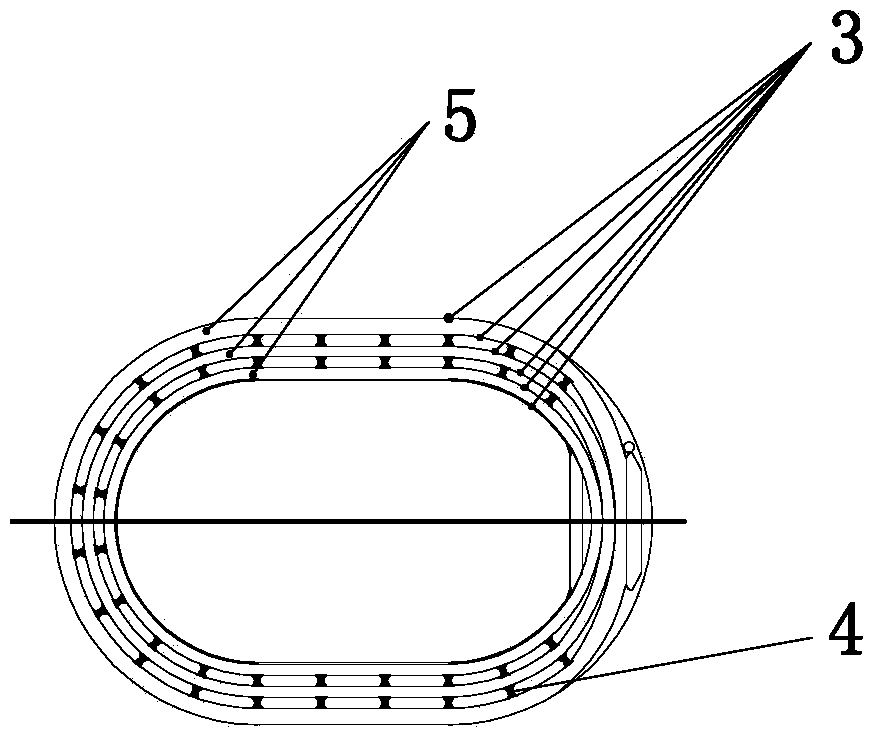

[0020] Embodiment one: if figure 1 , figure 2 As shown, the dry-type transformer low-voltage foil coil end sealing method of the present invention includes the following specific steps:

[0021] (1) When the low-voltage coil 1 is winding, the upper end surface 1.1 does not place the end insulation made of epoxy resin prepreg, and places a thickness of 0.5mm on the innermost layer, outermost layer and both sides of the stay 4 The epoxy board 3, the epoxy board 3 should be close to the baffle plate 2, and the pouring groove 5 is formed between the adjacent epoxy boards 3; the end insulation made of the epoxy resin prepreg is a market purchase product;

[0022] (2) According to the process requirements, the low-voltage coil 1 is cured in an oven, and after leaving the oven, the low-voltage coil 1 is demoulded when the temperature of the low-voltage coil 1 drops below 40°C;

[0023] (3), apply glass glue at the slit of each pouring groove 5; this glass glue is a market purchase...

Embodiment 2

[0031] Embodiment two: if figure 1 , figure 2 As shown, the dry-type transformer low-voltage foil coil end sealing method of the present invention includes the following specific steps:

[0032] (1) When the low-voltage coil 1 is winding, the upper end surface 1.1 does not place the end insulation made of epoxy resin prepreg, and places a thickness of 0.5mm on the innermost layer, outermost layer and both sides of the stay 4 The epoxy board 3, the epoxy board 3 should be close to the baffle plate 2, and the pouring groove 5 is formed between the adjacent epoxy boards 3; the end insulation made of the epoxy resin prepreg is a market purchase product;

[0033] (2) According to the process requirements, the low-voltage coil 1 is cured in an oven, and after leaving the oven, the low-voltage coil 1 is demoulded when the temperature of the low-voltage coil 1 drops below 40°C;

[0034] (3), filling the non-alkali glass ribbon at the gap of each pouring groove 5; the alkali-free gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com