Mechanized full film furrow and ridge cultivation method of dry-farmed potato

A cultivation method and potato technology, which are applied in the fields of botanical equipment and methods, horticulture, application, etc., can solve the problems of time-consuming, labor-intensive, and difficult to match the width of the harvest, and the seedlings are not placed in time, so as to solve pollution and increase production. Significant effect and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

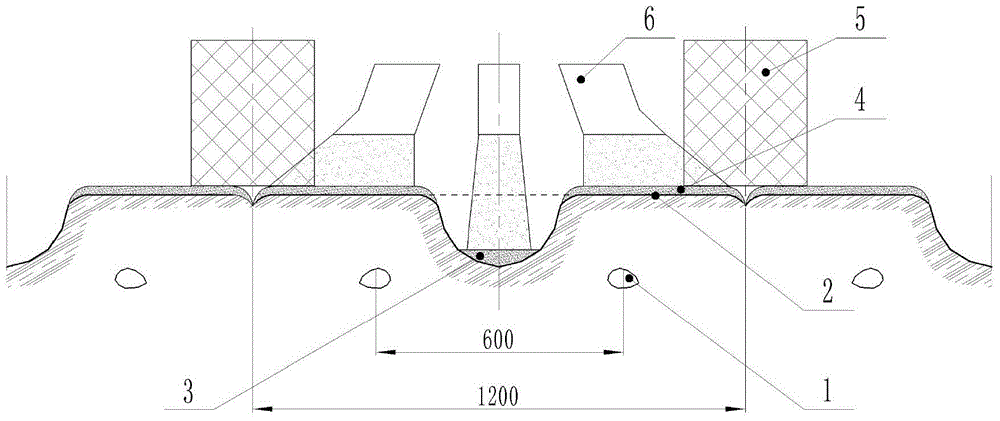

[0031] Example 1: see figure 1 , seed potato 1, mulch film 2, ditch bottom press soil 3, film top seat soil 4, machine support wheel 5, soil discharge trough 6.

[0032] A mechanized full-film furrow and ridge cultivation method for dry-farming potatoes, the main feature of which is that the steps are:

[0033] (1) Pre-broadcast preparation:

[0034] 1) Site selection:

[0035] The land selection requires the land to be flat, and the stubble should be plowed deeply within 15 days after the harvest of the previous crop in autumn. The plow should be plowed to a depth of 30 cm, and the plow should be harrowed within 2 days after plowing. Rotary tiller with rotary tiller, the plowing depth reaches 20 cm, so that the ground is flat, no stubble, no rubbish, no residual film;

[0036] 2) Disinfection:

[0037] The knife used for cutting is sterilized with 0.5% potassium permanganate; the cut potato pieces are seeded with plant ash, so that the incision is evenly stained with plan...

Embodiment 2

[0054] Example 2: see figure 1 , seed potato 1, mulch film 2, ditch bottom press soil 3, film top seat soil 4, machine support wheel 5, soil discharge trough 6.

[0055] A method for mechanized full-film furrow and ridge cultivation of dry-farmed potatoes, the steps of which are:

[0056] (1) Pre-broadcast preparation:

[0057] 1) Site selection:

[0058] The land selection requires the land to be flat, and the stubble should be plowed deeply within 10 days after the harvest of the first crop in autumn, and the plow should be plowed with a turning plow to a depth of 25 cm. After plowing, it should be harrowed within 1 day; Rotary tiller with rotary tiller, the plowing depth reaches 15 cm, so that the ground is flat, no stubble, no rubbish, no residual film;

[0059] 2) Disinfection:

[0060] The knife used for cutting is sterilized with 0.5% potassium permanganate; the cut potato pieces are seeded with plant ash, so that the incision is evenly stained with plant ash, and t...

Embodiment 3

[0077] Embodiment 3: a kind of mechanized full-film furrow and ridge cultivation method of dry-farming potatoes is to adopt 2CM-2 type full-film double-furrow potato seeder sowing on the field after rotary tiller and soil preparation machine operation, 2 rows, row spacing 58cm , the plant spacing is 30cm, the sowing depth is 16cm (the distance between the seed potatoes and the ridge surface), and then the seed ditch is covered with soil to suppress; at the same time, 2 rows of chemical fertilizers are applied to the inside of the 2 rows of seed potatoes; After taking the soil, a trench with a width of 30cm and a depth of 15cm is formed; at the same time, the mulching device on the planter covers the sown field with a mulch film with a width of 138cm; finally, the soil conveying and dividing mechanism on the planter covers the finely divided soil in the furrows and seed rows Above, the covering height of the planting row is 5cm of soil; when the 2CM-2 type full-film furrow plant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com