Extrusion die with multiple corners and forming method thereof

A corner extrusion and corner technology, applied in the field of material extrusion, can solve the problems of cumbersome process and uneven deformation of extrusion blanks, and achieve the effects of simple mold structure, overcoming uneven structure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

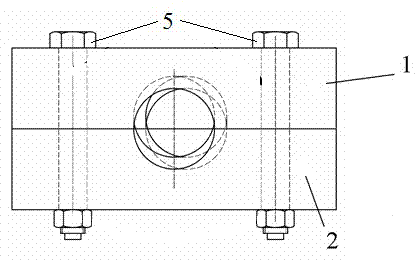

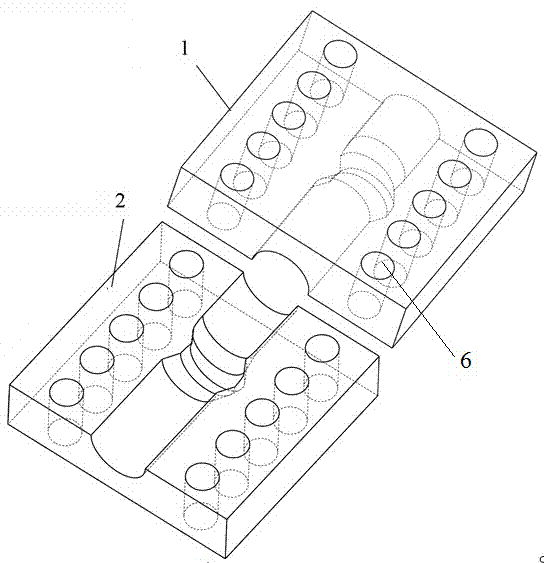

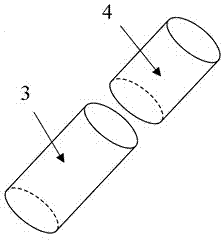

[0036] Such as Figure 1~5 As shown, a multi-rotational extrusion die includes a punch 3, a bolt 5, an upper die 1 and a lower die 2, the upper die 1 and the lower die 2 are tetrahedral, and the lower surface of the upper die 1 is provided with a downward The upper surface of the lower die 2 is provided with upward grooves, and bolt holes 6 are uniformly arranged on both sides of the grooves of the upper die 1 and the lower die 2, and the upper die 1 and the lower die 2 are fastened together, and the bolts 5 Solid, the grooves of the upper die 1 and the lower die 2 form an extrusion mold cavity, and the extrusion mold cavity is a multi-angle extrusion cavity; as Figure 4 As shown, the multi-corner extrusion cavity is sequentially divided into a guide section cavity 7, a first corner cavity 8, a second corner cavity 9, a third corner cavity 10, and a fourth corner cavity from the extrusion inlet. Cavities 11 and shaping section cavities 12, in which the cross-sections of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com