Air suspension

An air suspension, air spring technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve the requirements of high strength performance of guide spring, unfavorable improvement of vehicle ride comfort, high stiffness of guide spring 03, etc. problems, to achieve the effect of compact structure, reduced motion interference, and reduced stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

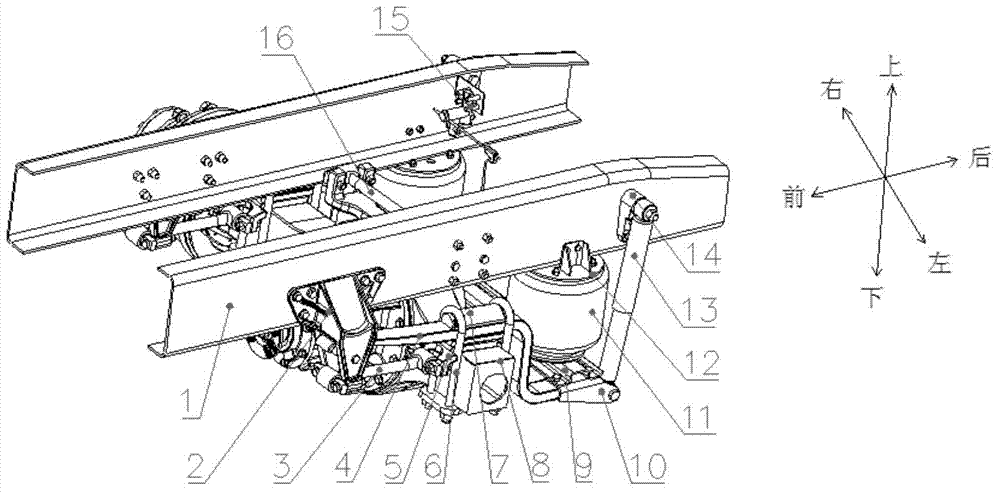

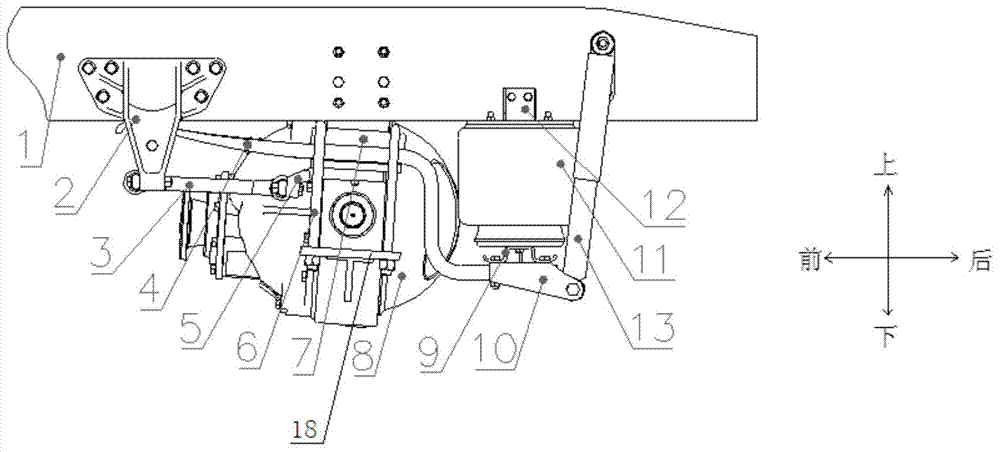

[0036] Next, specific embodiments of the present invention will be further described in detail with reference to the accompanying drawings, and in the following description, the up-down direction is defined as the vertical direction, the front-rear direction is defined as the longitudinal direction, and the left-right direction is defined as the horizontal direction.

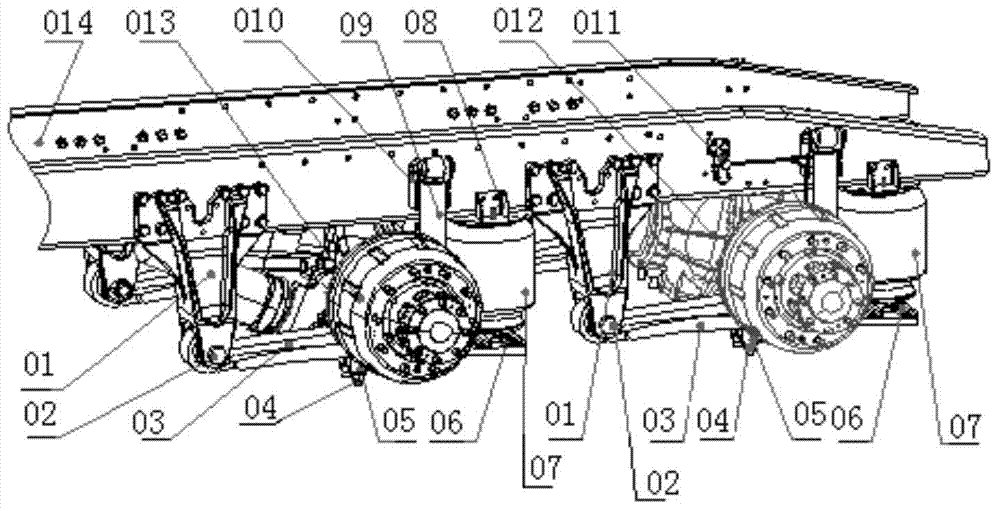

[0037] combine Figure 2 to Figure 5 , the air suspension in this embodiment includes: vehicle frame 1, front end bracket 2, guide thrust rod 3, bearing spring 4, guide thrust rod support 5, saddle bolt 6, leaf spring cover plate 7, axle 8, crossbeam 9. Rear end bracket 10, air spring 11, shock absorber 13, height valve assembly 15 and lateral thrust rod 16. The vehicle frame 1 has a pair of longitudinal beams extending in the front-rear direction and parallel to each other. From image 3 It can be seen more clearly that the bearing spring 4 is roughly Z-shaped, the front end of the bearing spring 4 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com