Steel pipe automatic three-dimensional access device

An auto-stereoscopic and storage device technology, applied in storage devices, transportation and packaging, etc., can solve the problems of scattered everywhere, easy rusting of steel pipes, time-consuming and laborious handling, etc., and achieves the effect of saving power resources, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

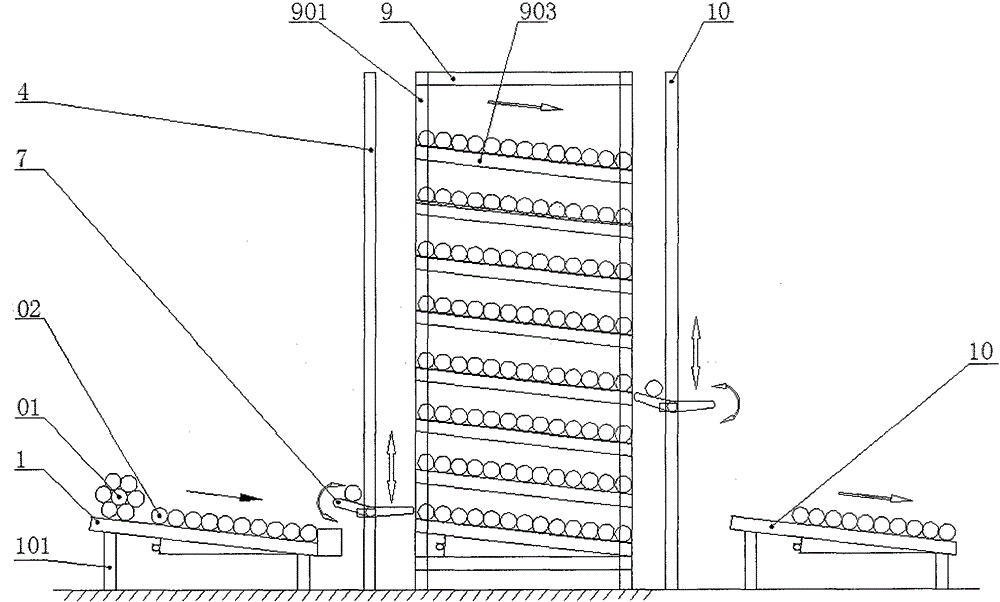

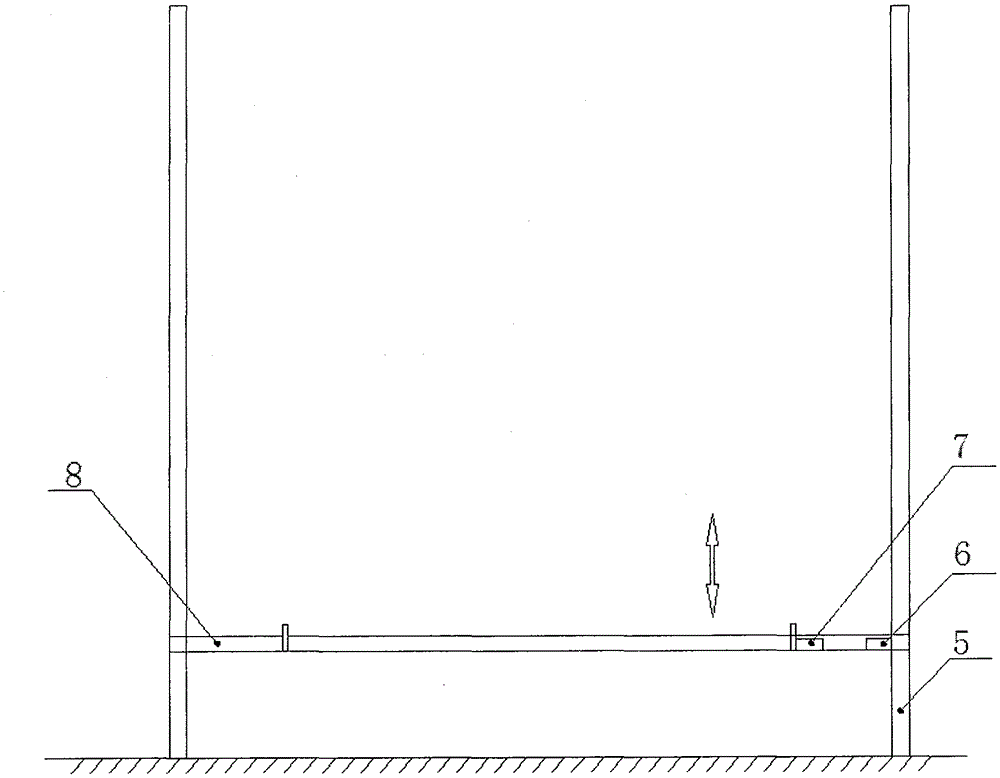

[0026] An automatic three-dimensional storage device for steel pipes, comprising a unbundling frame, a storage unit, a box-shaped three-dimensional shelf, a storage unit, and a matching control system and warehouse management system.

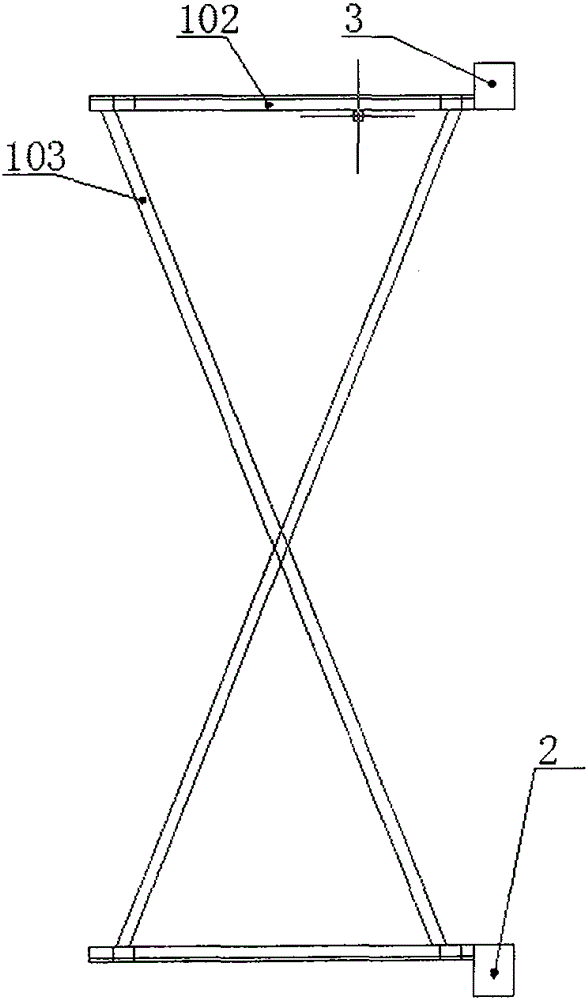

[0027] Described unbundling rack 1 is positioned at box-type three-dimensional shelf 9 fronts, as figure 1 , figure 2 , the lower part of the unbundling frame 1 is the outrigger 101, which is installed on the ground, the bundled steel pipe 01 and the single steel pipe 02 after unbundling are stacked on the longitudinal beam 102, and the longitudinal beam is tightened and fixed by the crossbeam 103. The above structures are profiled Rigid connection structure, there is an angle α between the longitudinal beam and the horizontal plane, after the steel pipe is unbundled, it will roll to the lower end by gravity, and a laser length m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com