System and method for treating high-organic-matter-content high-ammonia-nitrogen wastewater by UASB/A/MBBR (upflow anaerobic sludge blanket/anoxic/moving bed biofilm reactor) combined chemical process

A technology of organic matter and chemical method, applied in low-cost fields, can solve problems such as unsatisfactory purification effect, achieve low-cost and high-efficiency purification treatment, improve biodegradability, and save energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

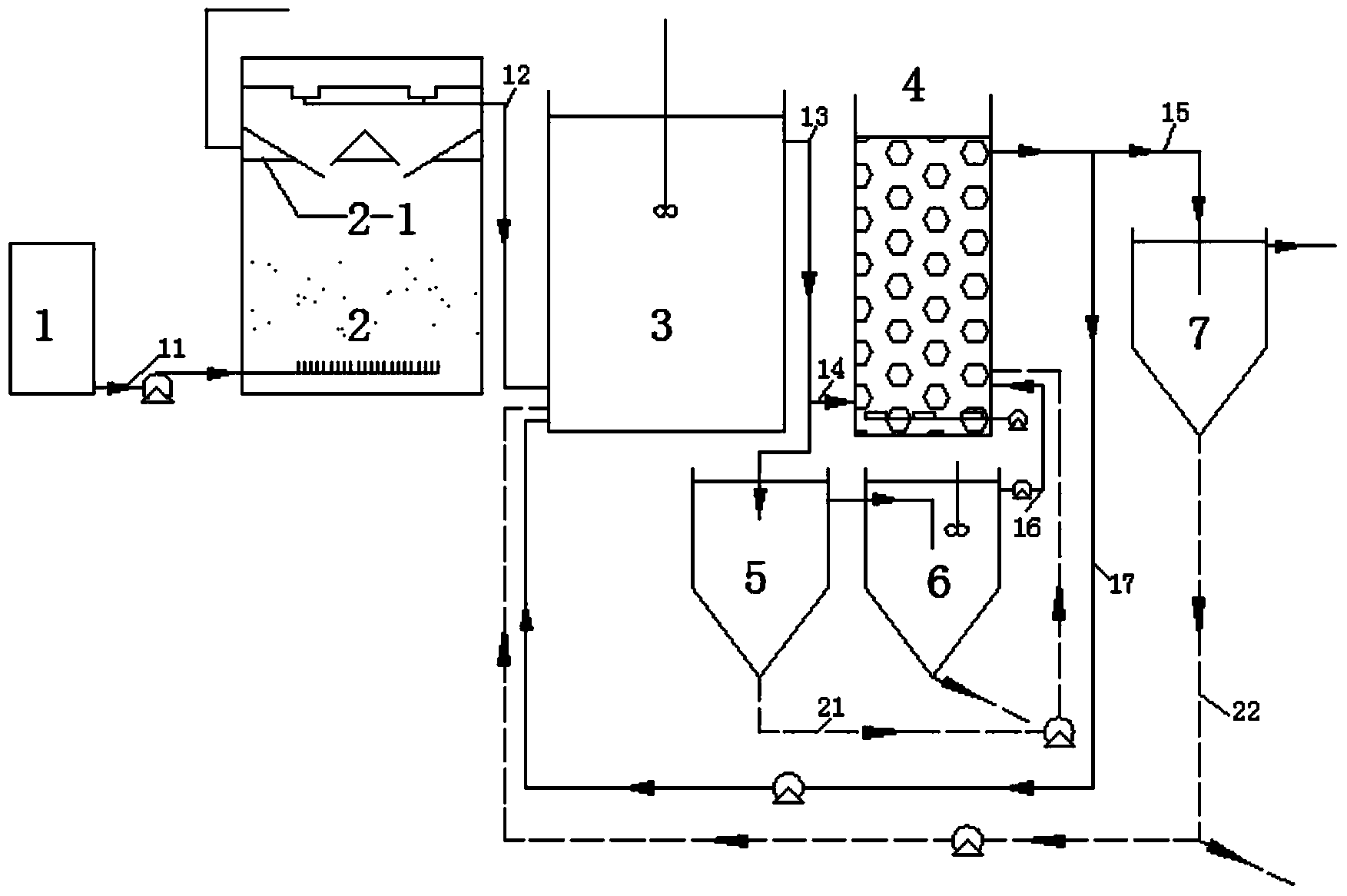

[0027] Specific Embodiment 1: In this embodiment, the UASB / A / MBBR combined chemical method for treating wastewater with high organic matter and high ammonia nitrogen includes UASB reactor 2, anoxic tank 3, MBBR reactor 4, sedimentation tank 7, middle sedimentation tank 5 and chemical The sedimentation tank 6 and the regulating tank 1 communicate with the water inlet located at the bottom of the UASB reactor 2 through the No. 1 water pipe 11, and a three-phase separator 2-1 is installed on the upper part of the UASB reactor 2, and the water outlet located at the upper part of the UASB reactor 2 Communicate with the first water inlet of anoxic tank 3 by No. two water pipes 12, and the water outlet of anoxic tank 3 top is connected to the water inlet of intermediate sedimentation tank 5 top by No. three water pipes 13, and the water outlet of intermediate sedimentation tank 5 is connected with chemical The water inlet of the sedimentation tank 6 is connected, the water outlet of t...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 1 in that an anoxic tank 3 and a chemical precipitation tank 6 are provided with stirring devices.

specific Embodiment approach 3

[0031]Specific embodiment three: this embodiment is different from specific embodiment one or two in that a nitrifying liquid return pump is provided in the return pipe 17, and a sludge return flow is provided in the No. 1 sludge discharge pipe 21 and the No. 2 sludge discharge pipe 22 Pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com