High-temperature piezoelectric ceramic material and preparation method thereof

A technology of piezoelectric ceramics and ceramic materials, which is applied in the field of piezoelectric ceramics with high Curie temperature and its preparation, can solve the problems that the comprehensive electrical properties cannot meet the requirements of device use at the same time, and the price is high, and achieves low dielectric loss and preparation cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

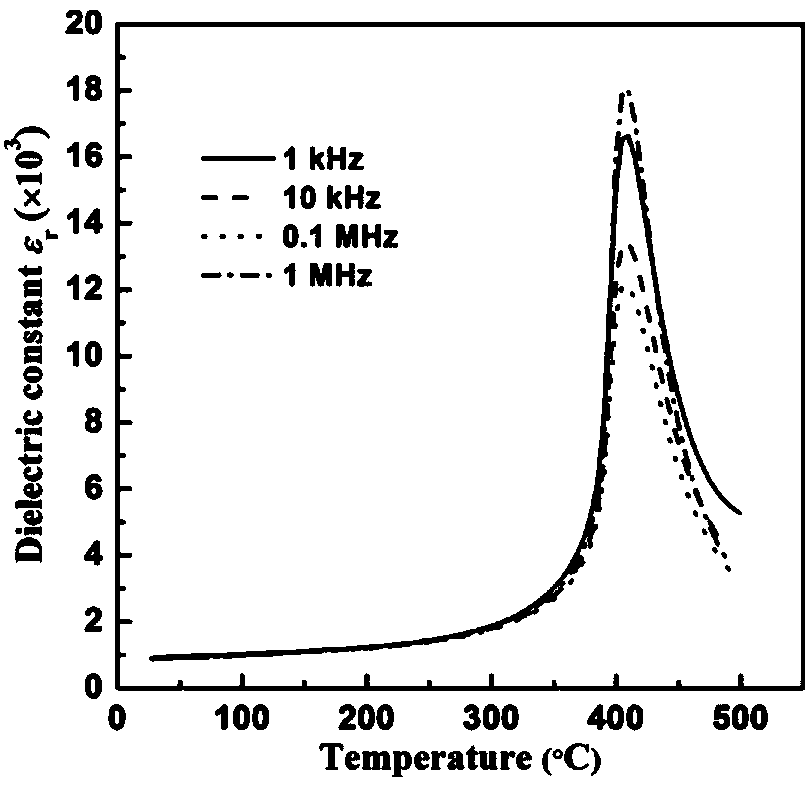

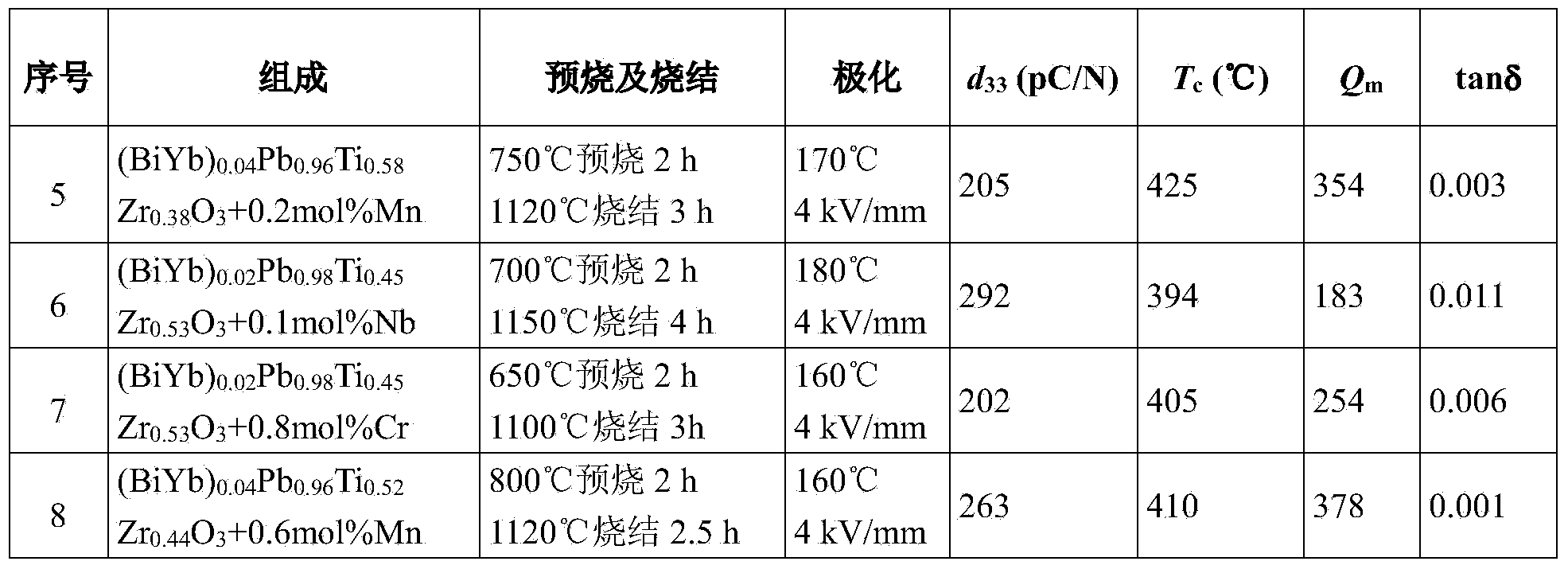

Embodiment 1

[0025] Bi 2 o 3 , Yb 2 o 3 , Pb 3 o 4 、TiO 2 , ZrO 2 and MnCO 3 Press (BiYb) 0.07 Pb 0.93 Ti 0.49 Zr 0.44 o 3 ++Weigh the molar ratio of 1mol% Mn, add anhydrous ethanol medium to mix and ball mill, dry and sieve, pre-calcine at 750°C for 2h. The pre-fired block is then ball milled, dried and granulated with 5% PVA, aged for 6 hours, sieved and pressed into a green body with a diameter of 15mm and a thickness of about 1.5mm, and sintered at 1120°C for 2.5h. The obtained sample was ground, polished, silvered, and polarized in 160°C silicone oil with an electric field of 4kV / mm for 20 minutes, and the required ceramic sample was prepared after cooling down. The comprehensive electrical properties obtained from the test were: d 33 =213pC / N,T c =395°C, Q m =356, tanδ=0.002.

Embodiment 2

[0027] Bi 2 o 3 , Yb 2 o 3 , Pb 3 o 4 、TiO 2 , ZrO 2 and Nb 2 o 5 Press (BiYb) 0.06 Pb 0.94 Ti 0.5 Zr 0.44 o 3 ++ 0.2mol% Nb molar ratio weighing, adding water medium to mix and ball mill, drying and sieving, pre-calcined at 750°C for 2h. Ball mill the pre-fired block, dry it, add 6% PVA to granulate, age for 6 hours, press it into a green body with a diameter of 15mm and a thickness of about 1.5mm after sieving, and sinter at 1150°C for 3 hours to obtain After the sample is polished, polished, and silvered, it is polarized in 160°C silicone oil with an electric field of 4kV / mm for 10 minutes, cooled to 110°C and then polarized for 10 minutes to make a ceramic sample. The comprehensive electrical properties obtained from the test are: d 33=213pC / N, T c =390°C, Q m =156, tanδ=0.011.

Embodiment 3

[0029] Bi 2 o 3 , Yb 2 o 3 , Pb 3 o 4 、TiO 2 , ZrO 2 and Cr 2 o 3 Press (BiYb) 0.05 Pb 0.95 Ti 0.5 Zr 0.45 o 3 ++0.2mol%Cr molar ratio weighing, adding water medium to mix ball milling, drying and sieving, pre-calcined at 800°C for 2h. Ball mill the pre-fired block, dry it, add 5% PVA to granulate, age for 6 hours, press it into a green body with a diameter of 15mm and a thickness of about 1.5mm after sieving, and sinter at 1150°C for 3 hours to obtain After the sample is polished, polished, and silvered, it is polarized in 160°C silicone oil with an electric field of 4kV / mm for 10min to prepare a ceramic sample. The comprehensive electrical properties obtained from the test are: d 33 =220pC / N,T c =401°C, Q m =180, tanδ=0.001.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com