Manufacturing technology of p-xylylene dichloride

A manufacturing process and a technology for para-dichlorobenzyl, applied in the field of para-dichlorobenzyl manufacturing process, can solve problems such as operator's physical injury and environmental impact, and achieve the effects of increased product output, low consumption and reduced impurities

Inactive Publication Date: 2014-12-24

QIANJIANG XINYIHONG ORGANIC CHEM

View PDF5 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the process of obtaining the p-dichlorobenzyl finished product by the crystallization method, due to the centrifugal drying method, a large amount of organized discharge gas permeates the operating environment during the operation, and is accompanied by dust, which has a great impact on the environment. Great impact, and caused great harm to the operator's body

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0034] The present invention can be further understood by giving specific embodiments of the present invention in conjunction with the accompanying drawings below, but they are not limitations of the present invention. Some non-essential improvements and adjustments made by those skilled in the art based on the above content of the invention are also deemed to fall within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

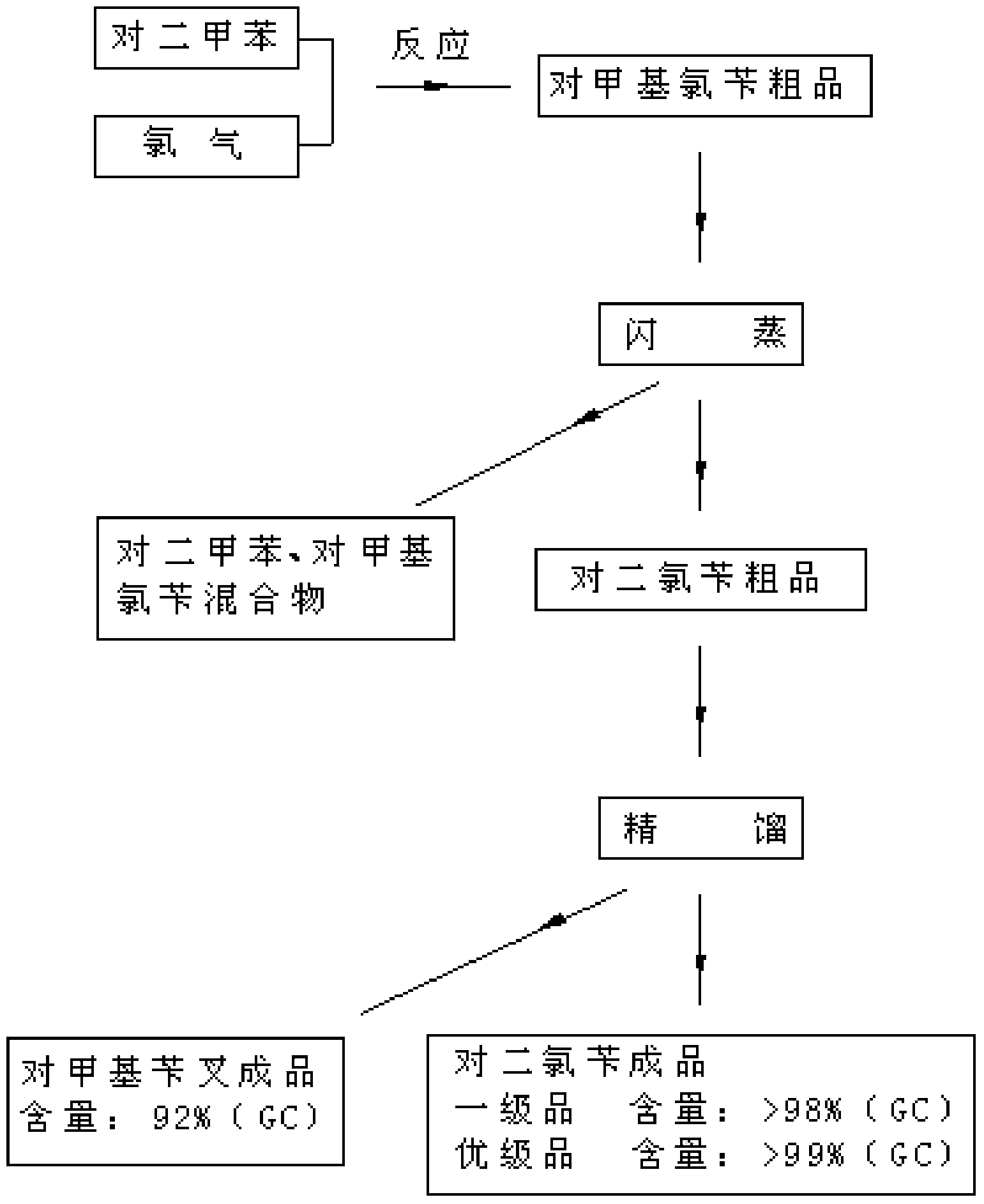

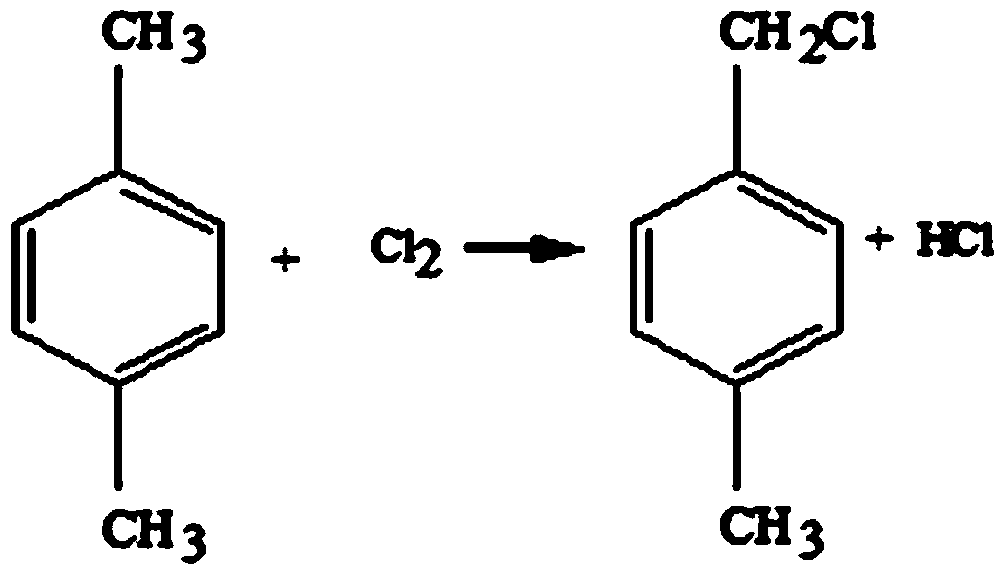

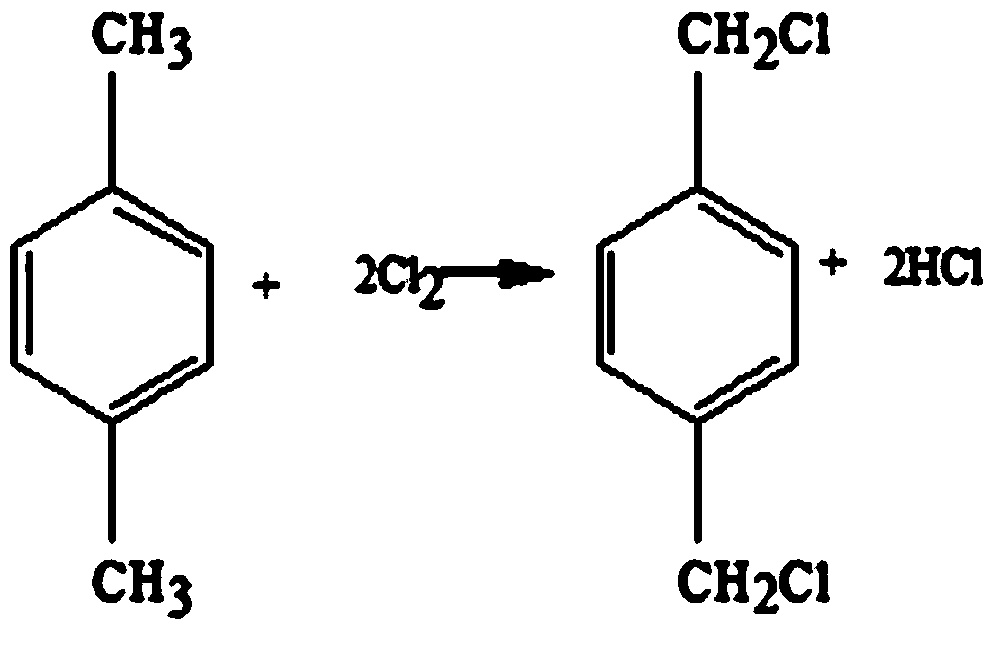

The invention provides a manufacturing technology of p-xylylene dichloride. The manufacturing technology comprises the following steps: (1) reaction: adding p-xylene in a chlorination reactor, turning on a reaction light source, and then turning on jacket steam of a reaction still to begin to heat and raise the temperature; when the temperature is raised to 80 DEG C, stopping steam heating, and introducing Cl2 to the reaction still; two hours after Cl2 introduction, increasing the chlorine flow, sampling to conduct center control analysis, and stopping introduction of the chlorine after meeting the process control requirements; (2) flash evaporation: simply distilling the mixed liquor obtained in the step (1), collecting the mixture of p-xylene and p-methylbenzyl chloride, and centrally collecting the bed charge inside the distillation still; (3) rectification: transferring the bed charge centrally collected in the step (2) to a benzylidene chloride rectifying column to be decompressed and rectified; collecting 4 mm Hg of fraction at 120-125 DEG C to obtain p-methylbenzylidene; collecting 4 mm Hg of fraction at 135-140 DEG C to obtain p-xylylene dichloride. The manufacturing technology disclosed by the invention can increase the yield of the product, achieves higher purity, and is easy for byproduct separation and purification.

Description

Technical field: [0001] The invention relates to the field of chemical industry, in particular to a process for producing p-dichlorobenzyl. Background technique: [0002] The traditional method for making p-dichlorobenzyl is to use glass reaction bottle to feed chlorine to obtain the p-methyl benzyl chloride crude product. In the crude product, p-xylene content is 60% (GC), and p-methyl benzyl chloride content is 30% (GC). The content of p-dichlorobenzyl is 3-5% (GC), the content of p-methylbenzylidene is 0.5-1.0% (GC), and the content of other impurities is 4% (GC). [0003] After flashing off p-xylene and p-methyl benzyl chloride, the residue of p-methyl benzyl chloride is obtained after rectification. Then, the finished product of p-dichlorobenzyl is obtained by cooling, crystallizing, centrifuging and drying with the offal of p-methyl benzyl chloride as raw material. However, in the process of obtaining the p-dichlorobenzyl finished product by the crystallization metho...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C22/04C07C17/14C07C17/383

Inventor 朱梦宁向世炎张勇

Owner QIANJIANG XINYIHONG ORGANIC CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com