High-strength edge folding glue

A hemming adhesive and high-strength technology, applied in the direction of adhesives, epoxy resin glue, non-polymer adhesive additives, etc., can solve the problems of weak T-shaped peel strength and separation, achieve enhanced strength, facilitate smearing, and improve The effect of intensity

Inactive Publication Date: 2014-12-24

张家港爱科思汽车配件有限公司

View PDF2 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] High-strength hemming adhesive mainly composed of epoxy resin, shear strength of steel plate (㎏ f / cm 2 ) is very strong, but the T-shaped peel strength will be weaker accordingly, and it cannot play the role of high-strength adhesive force and cause the separation of steel plates and steel plates

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

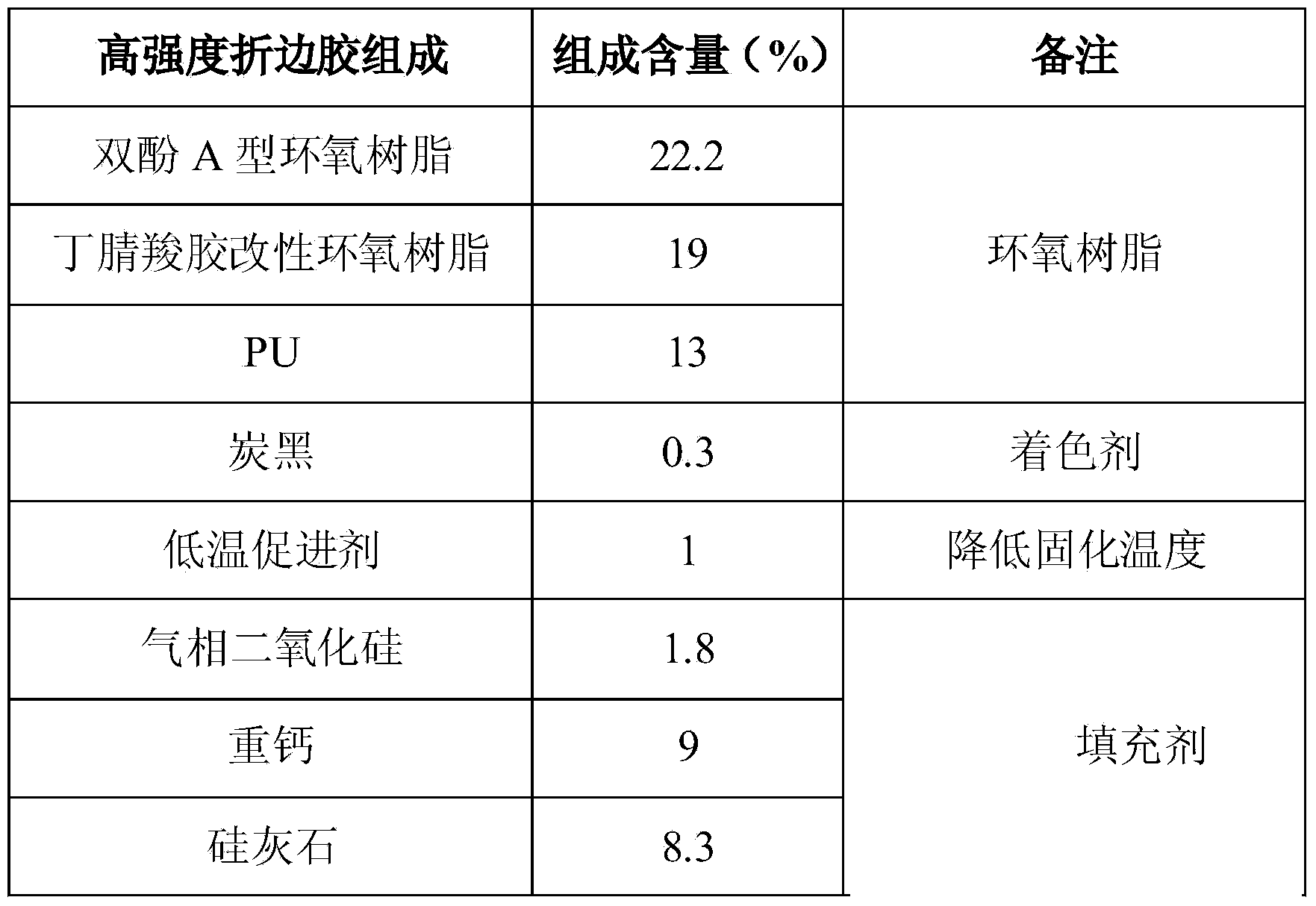

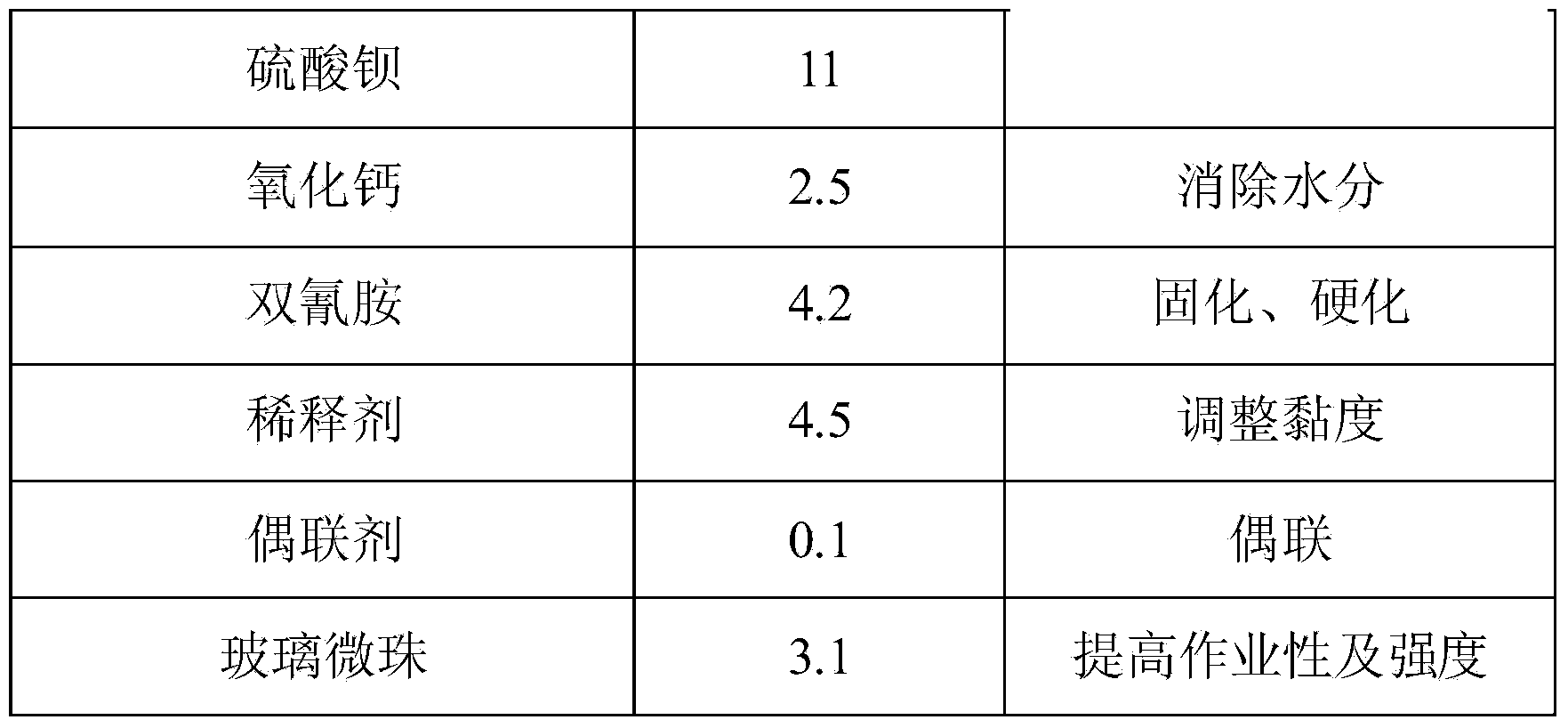

Embodiment 1

[0010]

[0011]

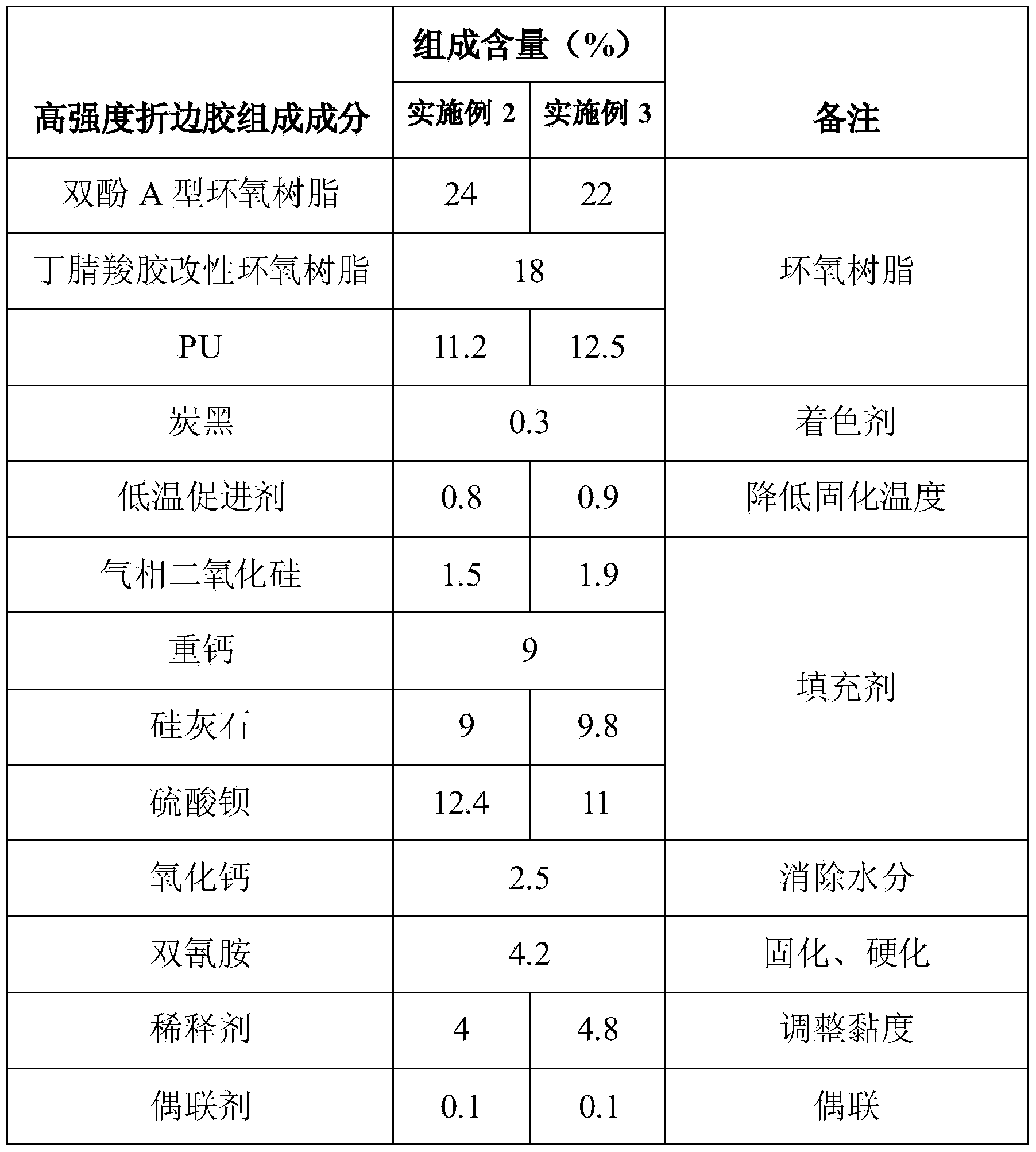

Embodiment 2~3

[0013]

[0014]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses high-strength edge folding glue which comprises the following components in mass percent: 22-27 percent of bisphenol-A epoxy resin, 16-20 percent of nitrile carboxylic rubber modified epoxy resin, 11-14 percent of PU, 4-5 percent of dicyandiamide, 0.8-1.1 percent of a low-temperature promoter, 1.5-2 percent of fumed silica, 8-10 percent of ground calcium carbonate, 8-10 percent of wollastonite, 10-13 percent of barium sulfate, 3-3.3 percent of glass beads, 0.3-0.5 percent of carbon black, 2.2-2.8 percent of calcium oxide, 0.1-0.15 percent of a coupling reagent and 4-5 percent of a diluent. According to the technical scheme disclosed by the invention, from the aspects of the bonding performance of the high-strength edge folding glue with a steel plate and the improvement on the strength of cured products, the effects of facilitating the painting on the steel plate, insulating sound, absorbing shock and effectively enhancing the strength are achieved.

Description

technical field [0001] High-strength hemming glue is a black paste product with epoxy resin as the main component. It is suitable for the inside of the hemming of the car cover, door, etc. It is completely hardened after being painted and baked to produce strong adhesion and Rust prevention as the main purpose of thermosetting products. Background technique [0002] It is mainly used to apply on the edge of the car door, the inner and outer panels of the front and rear covers, and play the role of waterproof, rustproof and bonding. Traditional car doors and front and rear covers need to be welded to fix the inner and outer panels, which not only increases the process, but also affects the appearance. High-strength hemming glue High-strength hemming glue with high bonding strength, good friction performance with steel plates, and stable colloid is in great demand in the market. [0003] High-strength hemming adhesive mainly composed of epoxy resin, shear strength of steel p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J163/00C09J175/04C09J11/04C09J11/06

Inventor 裴仁哲蔡岳斌

Owner 张家港爱科思汽车配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com