An automatic temperature control system for top-blown oxygen converter steelmaking and its application method

An automatic control system and automatic temperature control technology, which is applied in the field of converter steelmaking temperature control, can solve the problems of automatic control of molten steel temperature, potential safety hazards, and inability to accurately measure molten steel temperature, achieving anti-dust and smoke interference and wide temperature control range , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

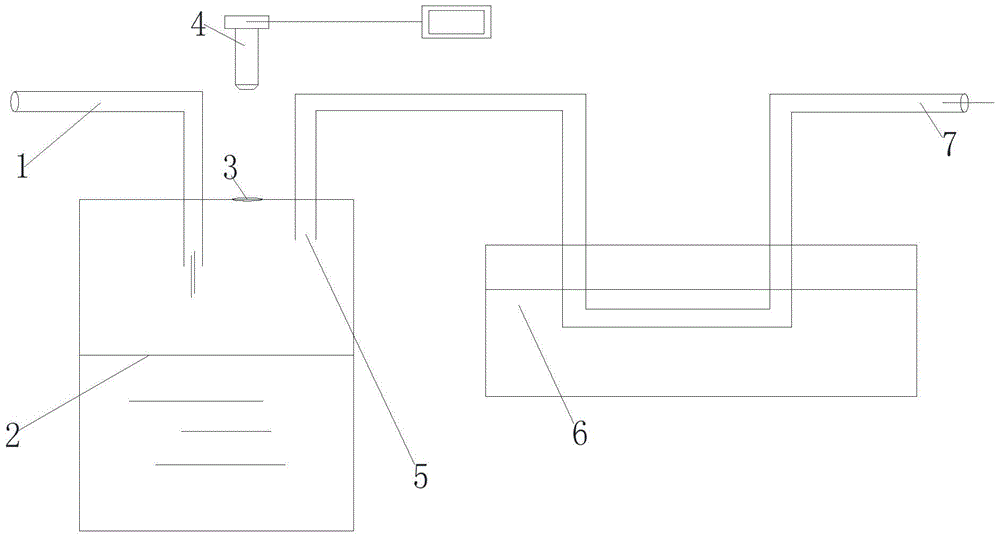

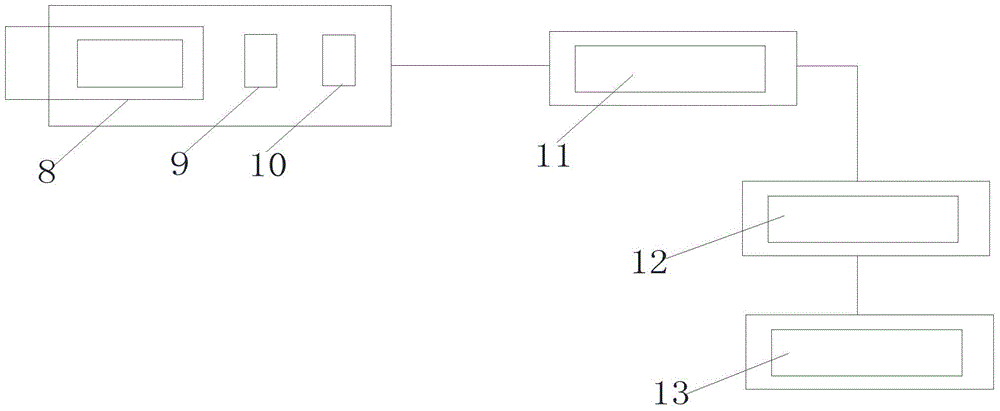

[0045] Such as figure 1 with figure 2 As shown, the present invention is an automatic temperature control system for top-blown oxygen converter steelmaking. The top of the top-blown oxygen converter is provided with an oxygen blowing duct 1 and an exhaust gas collection duct 5. The oxygen blowing duct 1 communicates with the inside and outside of the top-blown oxygen converter and is located Above the molten steel level 2, the exhaust gas collection pipe 5 communicates with the exhaust gas outlet 7 through the exhaust gas cooling pool 6. The automatic temperature control system 4 in turn includes an optical receiving system 8, a two-color cross light path 9, a photoelectric conversion unit 10, and A / D modulus The conversion unit 11, the information processing unit 12 and the automatic control system 13, the top of the top-blowing oxygen converter is provided with a temperature measuring window 3 at the position between the oxygen blowing duct 1 and the exhaust gas collection du...

Embodiment 2

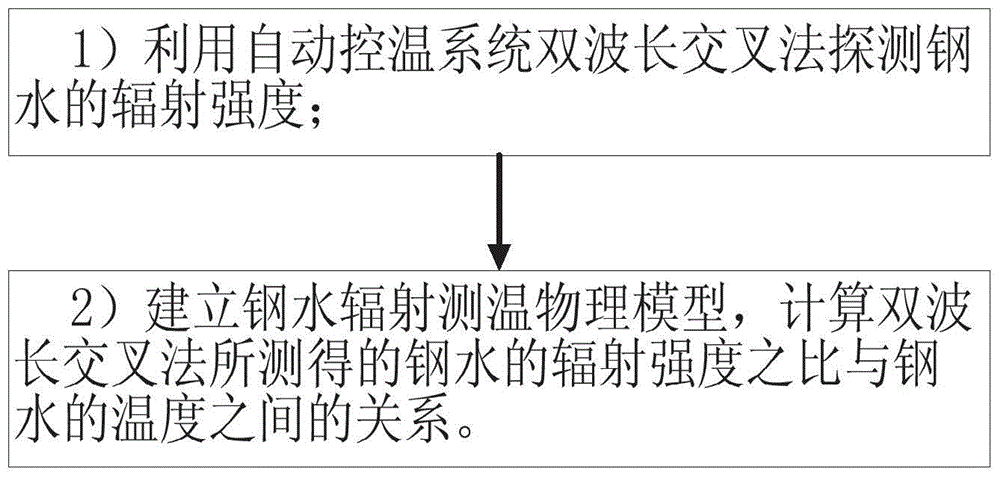

[0051] Such as Figure 1~3 As shown, the method for using an automatic temperature control system for top-blown oxygen converter steelmaking of the present invention includes the following steps:

[0052] 1) Detect the radiation intensity of molten steel using the automatic temperature control system 4 dual-wavelength crossover method;

[0053] 2) Establish a physical model of molten steel radiation temperature measurement, and calculate the relationship between the ratio of the radiation intensity of molten steel measured by the dual-wavelength crossover method and the temperature of molten steel.

[0054] The physical model of molten steel radiation temperature measurement includes the expression formula of the molten steel radiation intensity, the radiation correlation coefficient A and B, the radiation correlation coefficient A and B solution method, and the molten steel temperature solution method.

[0055] The expression formula for the radiation intensity of molten steel is:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com