CFRP cloth reinforcing structure of steel truss bridge steel tube tubular joints

A technology of intersecting nodes and steel truss bridges, applied in truss bridges, bridge reinforcement, erection/assembly of bridges, etc., can solve problems affecting the strength and stability of bridge structures, poor reinforcement effects, and complicated actual operations, and achieve superior mechanics performance, easy cutting, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

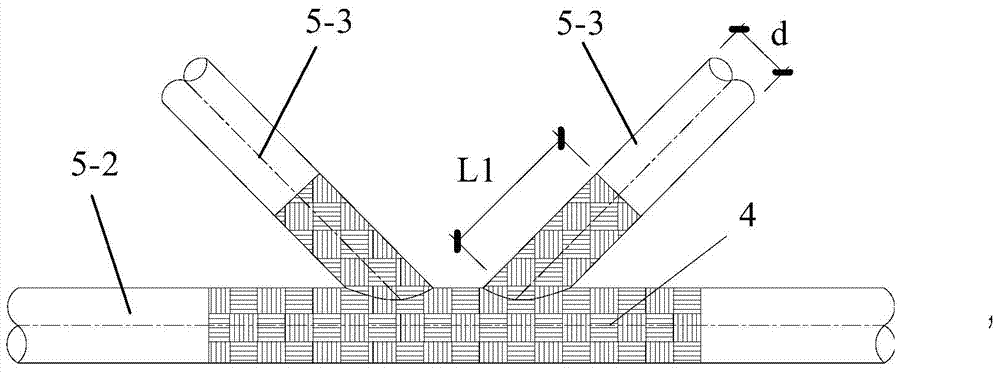

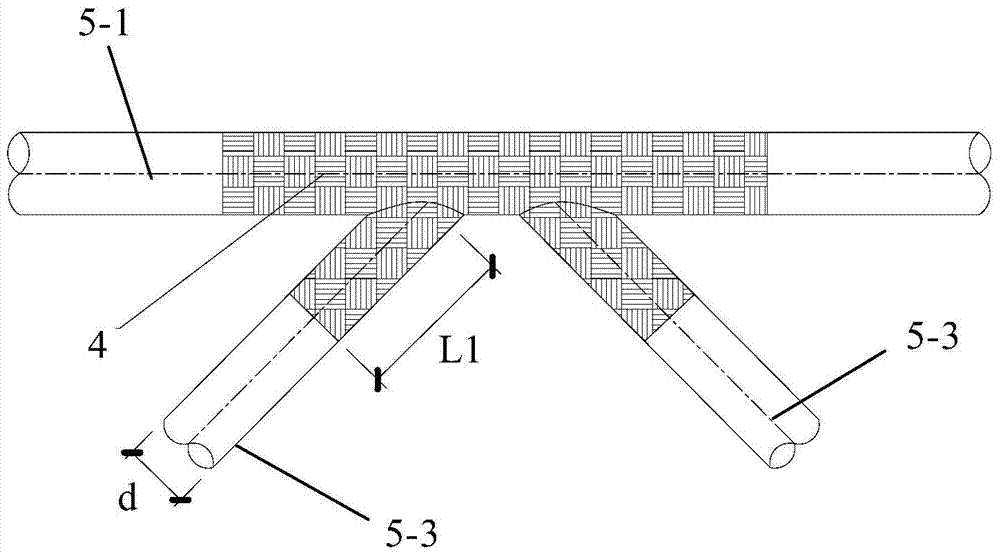

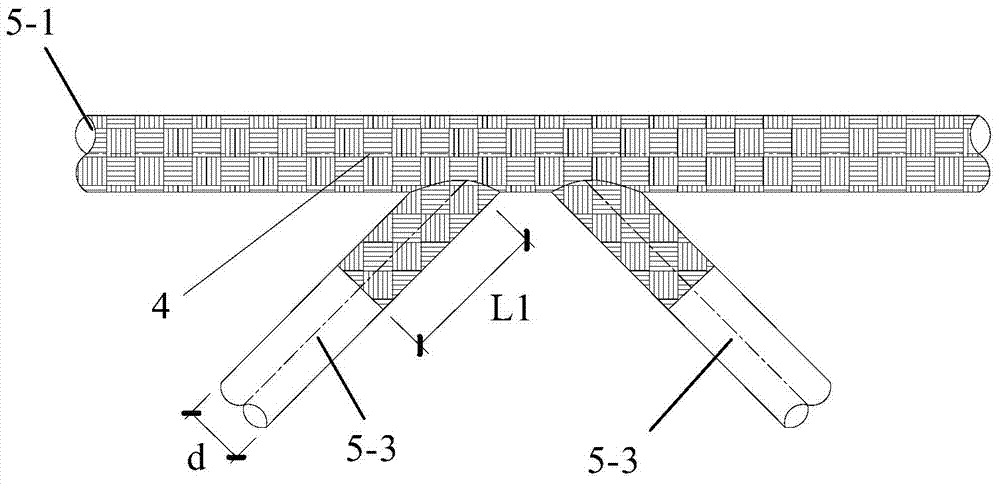

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention includes a GFRP cloth coating layer 1 coated on the outside of the intersecting node to be reinforced and a CFRP cloth coating layer 2 coated on the outside of the GFRP cloth coating layer 1, and the GFRP cloth coating layer 1 Both the inner and outer surfaces of the CFRP cloth covering layer 2 and the inner and outer surfaces of the CFRP cloth coating layer 2 are coated with a layer of adhesive coating 3. The number of the CFRP cloth covering layer 2 is one or more layers, and the multi-layer CFRP cloth covering layer 2 is covered on the outside of the GFRP cloth covering layer 1 from the inside to the outside, and the GFRP cloth covering layer 1 Between the intersecting nodes to be reinforced, between the CFRP cloth covering layer 2 and the GFRP cloth covering layer 1, and between the two adjacent layers of the CFRP cloth covering layer 2 are all bonded by adhesive co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com