Ultralong concrete slip form body of concrete rockfill dam and construction method of slip form body

A concrete rockfill dam and concrete technology, which is applied in dams, barrages, weirs and other directions, can solve the problems of insufficient construction technology of ultra-long concrete for rockfill dams, inability to achieve continuous pouring, and difficulty in meeting its construction requirements, etc. Repeated workload, obvious economic and social benefits, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the present invention, a concrete rockfill dam super-long concrete sliding form body and its construction method need to prepare the following materials:

[0044] 1. Stone, sand, cement, accelerator, steel bar, water stop, emulsified asphalt, etc.

[0045] 2. Machinery and equipment: cranes, loaders, excavators, transformers, welding machines, generators, tower cranes, straight thread machines, etc.

[0046] 3, technical parameter of the present invention (shown in table 1 to table 2):

[0047]

[0048] Table 1 Test results of cement physical properties

[0049]

[0050] Table 2 Concrete Construction Mix Ratio

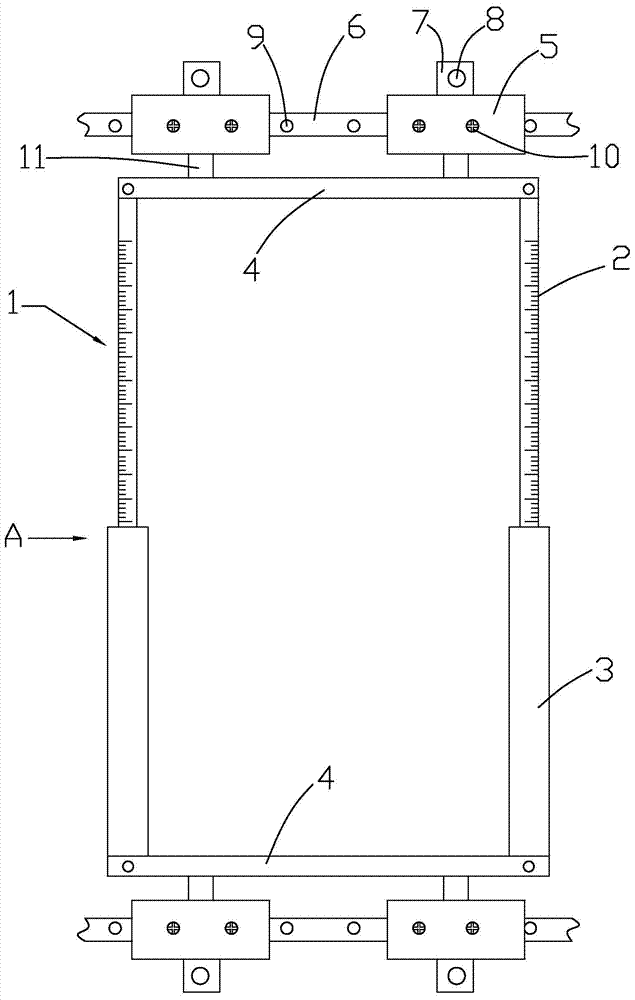

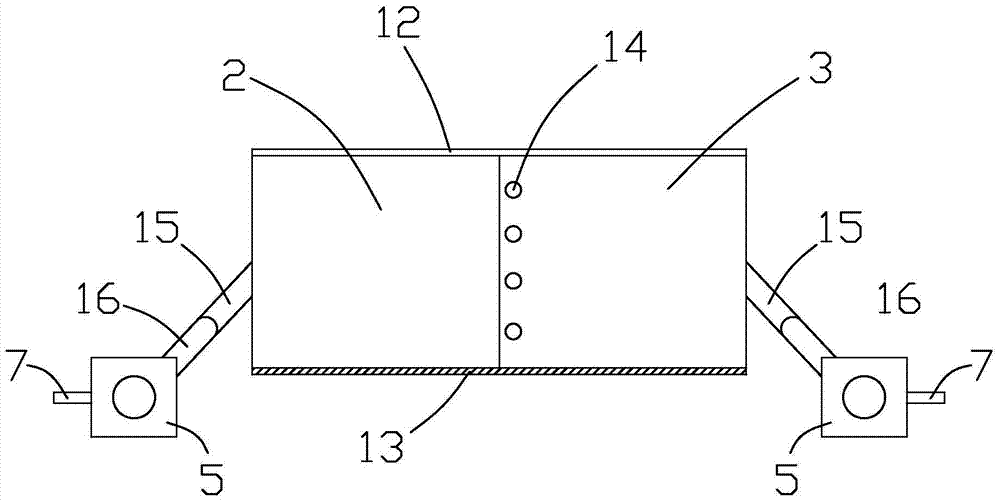

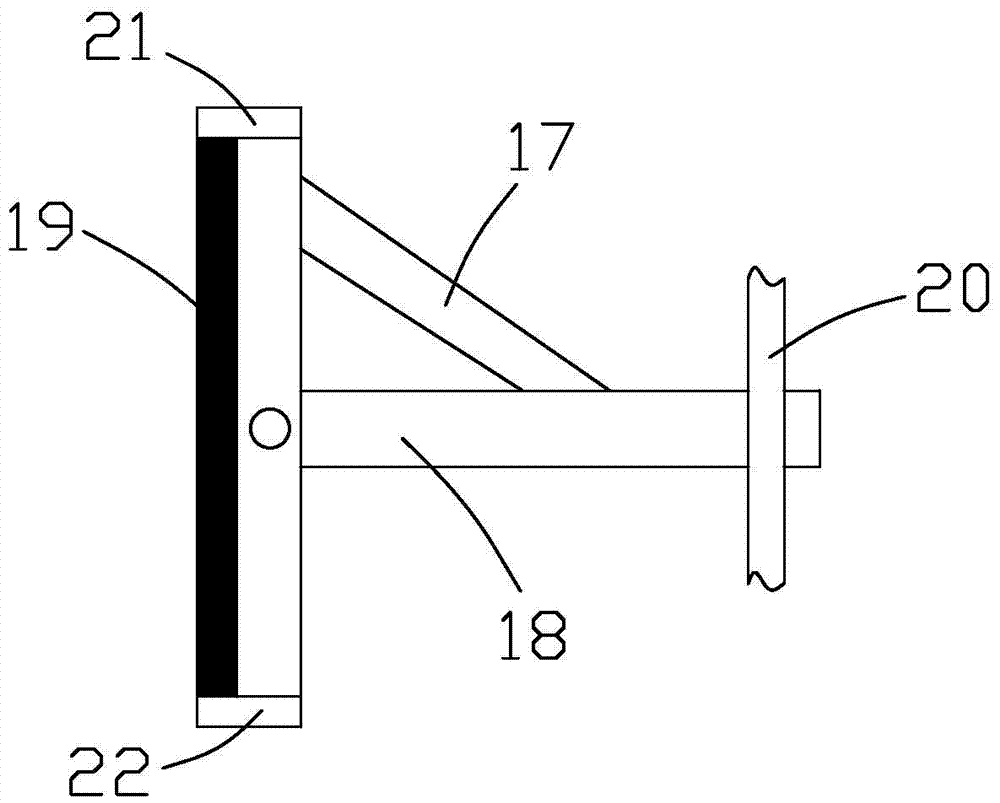

[0051]A kind of super-long concrete sliding form body of concrete rockfill dam (such as Figure 1 to Figure 3 As shown), the sliding form body 1 includes a fixed panel 2, a moving panel 3 and a positioning support plate 4, the two fixed panels 2 are connected through the positioning support plate 4, and the two moving panels 3 are connected through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com