Gas odorization unit

A gas and gas pipeline technology, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., to achieve the effects of low energy consumption, high degree of automation, and uniform concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

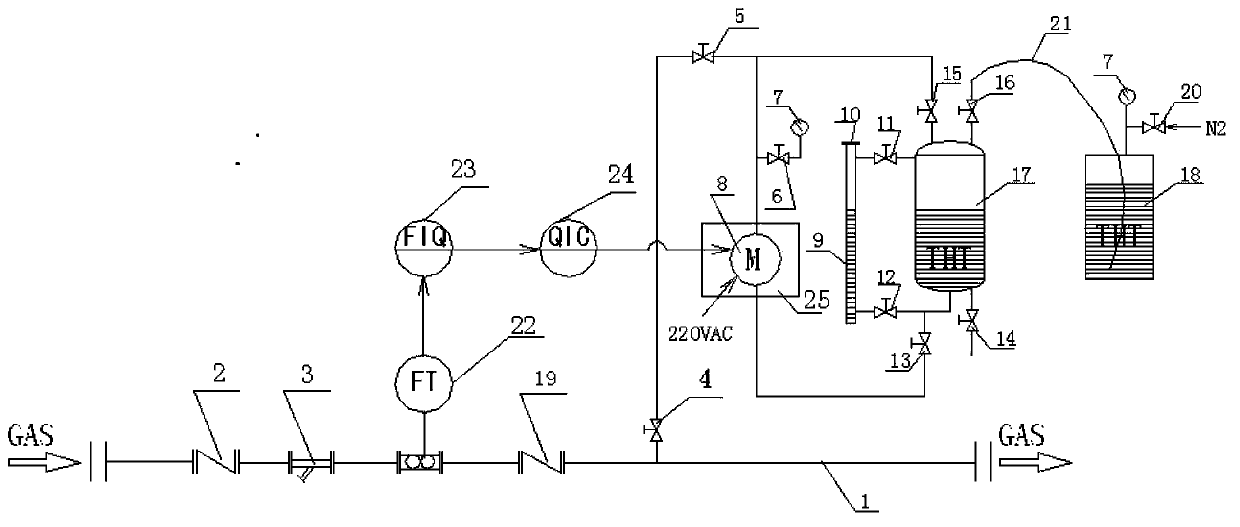

[0030] Such as figure 1 As shown, the gas odorizing device of the present invention includes a gas pipeline 1, an odor storage tank 17, an electromagnetic diaphragm pump 8, a flow meter 22, a flow totalizer 23 and an odorizing controller 24; the flow meter 22 is installed on On the gas pipeline 1, the flow meter 22 is connected to the flow totalizer 23, the flow totalizer 23 is connected to the odorizing controller 24, and the electromagnetic diaphragm pump 8 is connected to the odorizing controller 24;

[0031] The flow meter 22 and the flow totalizer 23 measure the gas flow in real time, and send the gas flow to the odorizing controller 24. The odorizing controller 24 will automatically calculate the odorizing amount according to the set odorizing ratio, and then output the pulse The signal is given to the electromagnetic diaphragm pump 8 to complete the automatic control process of the odorizing amount;

[0032] The top of the odor storage tank 17 is provided with a feed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com