Array type heat collecting device and control method thereof

A heat collecting device and array technology, which is applied in solar collector controllers, heating devices, solar thermal devices, etc., can solve the problems of complex drive system structure, waste of manpower and material resources, and large floor space, so as to reduce load bearing Strength requirements, cost saving, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

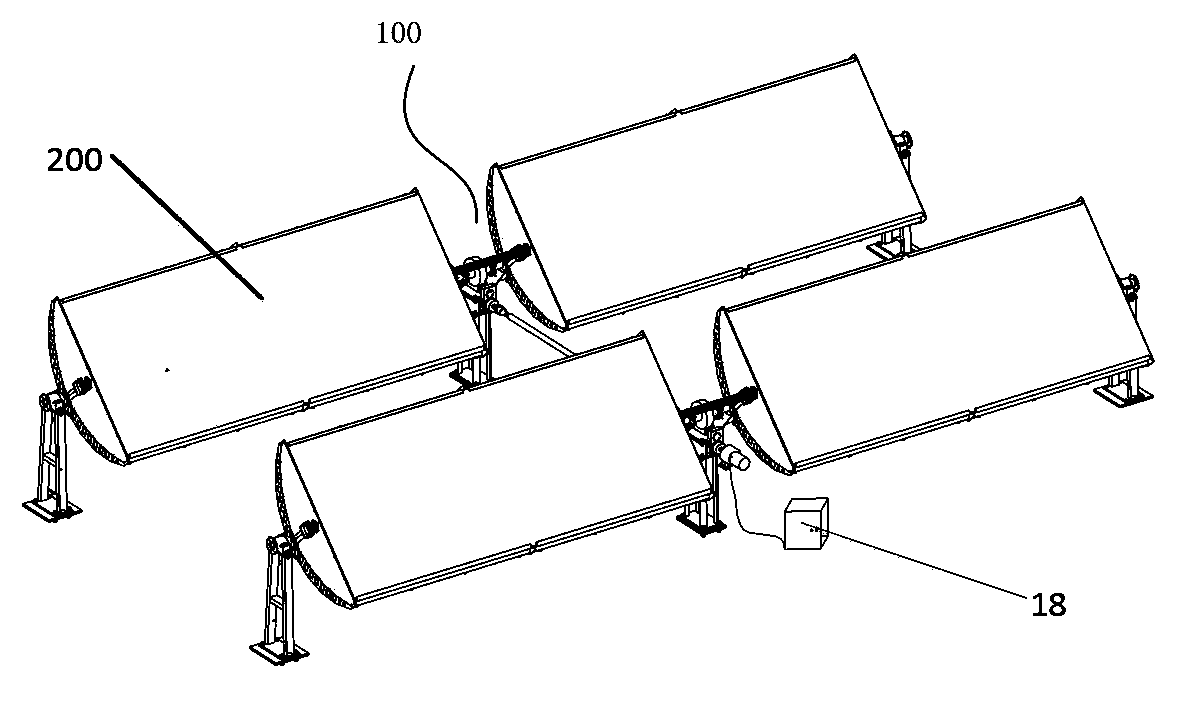

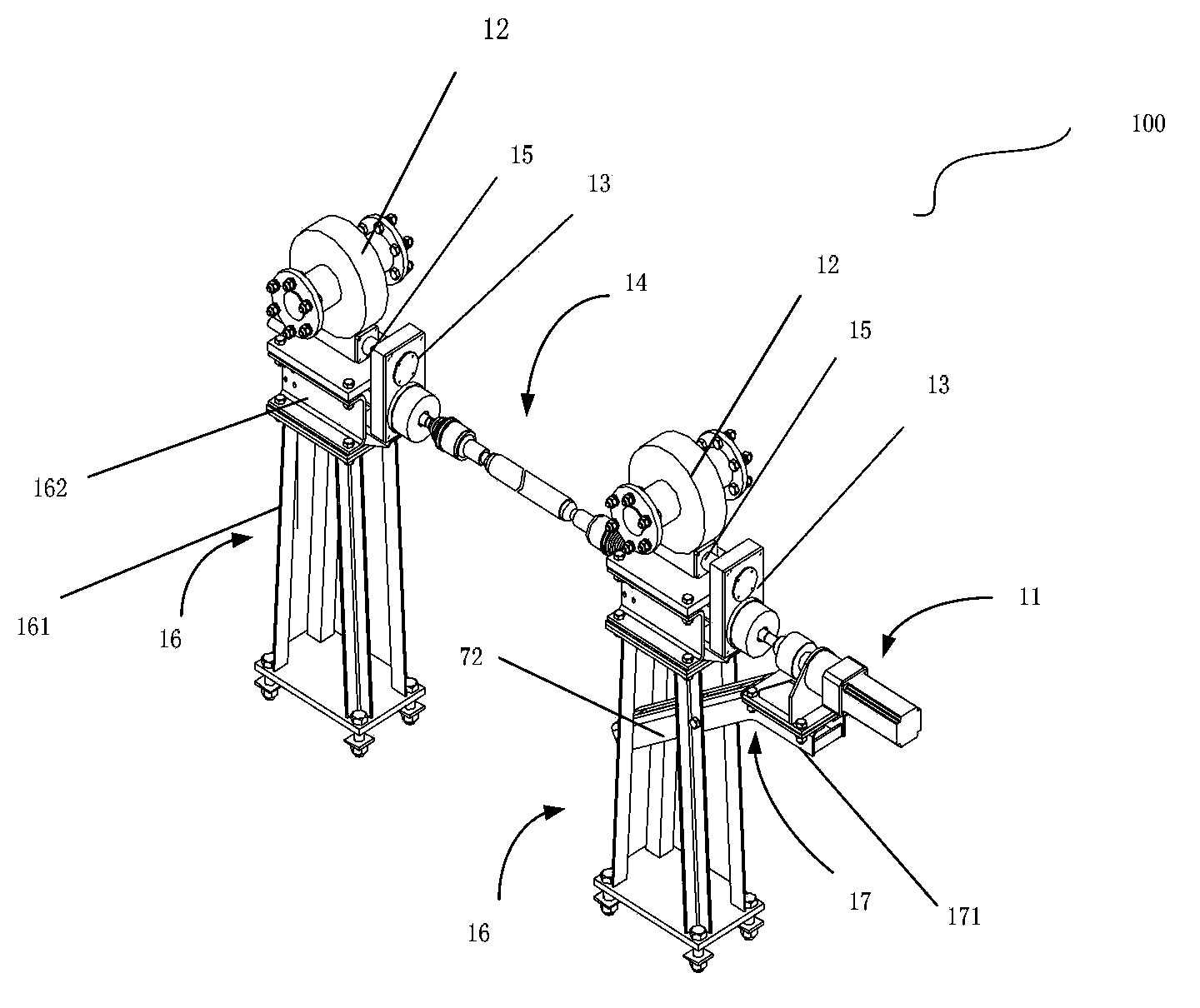

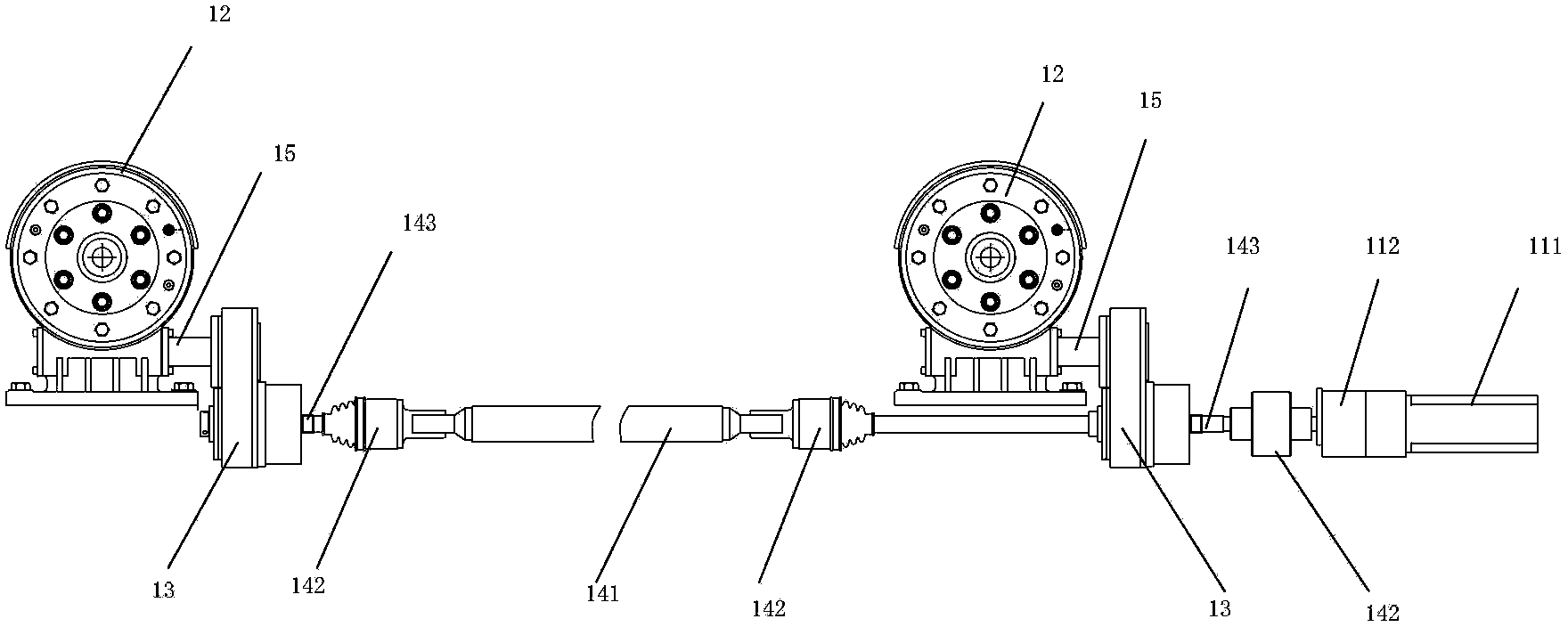

[0040] Such as figure 1 As shown, an array type heat collecting device proposed by the embodiment of the present invention includes four solar heat collectors 200 and a drive system 100. The four solar heat collectors 200 are connected in series to form a row, and two rows The solar heat collectors 200 are arranged in parallel, and four solar heat collectors 200 form an array of two rows and two columns. see figure 2 , the drive system 100 includes a power unit 11, a shaft transmission unit 14 and two sets of adjustment units, the drive system 100 is located on the central axis of the row in the array, and the two solar collectors 200 in the same row of the array heat collector correspond to one The above-mentioned adjustment unit, and each row is equipped with the above-mentioned adjustment unit, the number of rows and columns of solar collectors in the array heat collector can be adjusted according to needs, when the number of rows of solar collectors increases, only need ...

Embodiment 2

[0087] An embodiment of the present invention provides a method for controlling the array heat collecting device provided in Embodiment 1, the method comprising:

[0088] Step 101: adjusting the surface shape adjustment mechanism so that the surface shape of the solar collector meets the design requirements;

[0089] After the installation of the heat collector is completed, measure the size of the opening of the reflector. If the opening of the reflector is larger than the design opening after installation, unscrew the nut 55 of the surface adjustment mechanism, and add the gasket 56 according to the difference to make the opening meet the actual requirements. vice versa.

[0090] better, see Figure 8 , when installing the reflector bracket 223, due to the existence of installation errors, there is a certain deviation in the upper and lower positions of the lowest point of the bracket 223, by adjusting the position of the bolt 54 on the second fixing hole 531 to fix and ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com