Line scanning profile measurement method and device based on liquid level benchmark

A technology of contour measurement and liquid level reference, which is applied in the field of three-dimensional measurement, can solve the problems of measurement accuracy, such as the limitation of reflective characteristics, and achieve the effects of low application cost, simple implementation, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be described below in conjunction with the accompanying drawings.

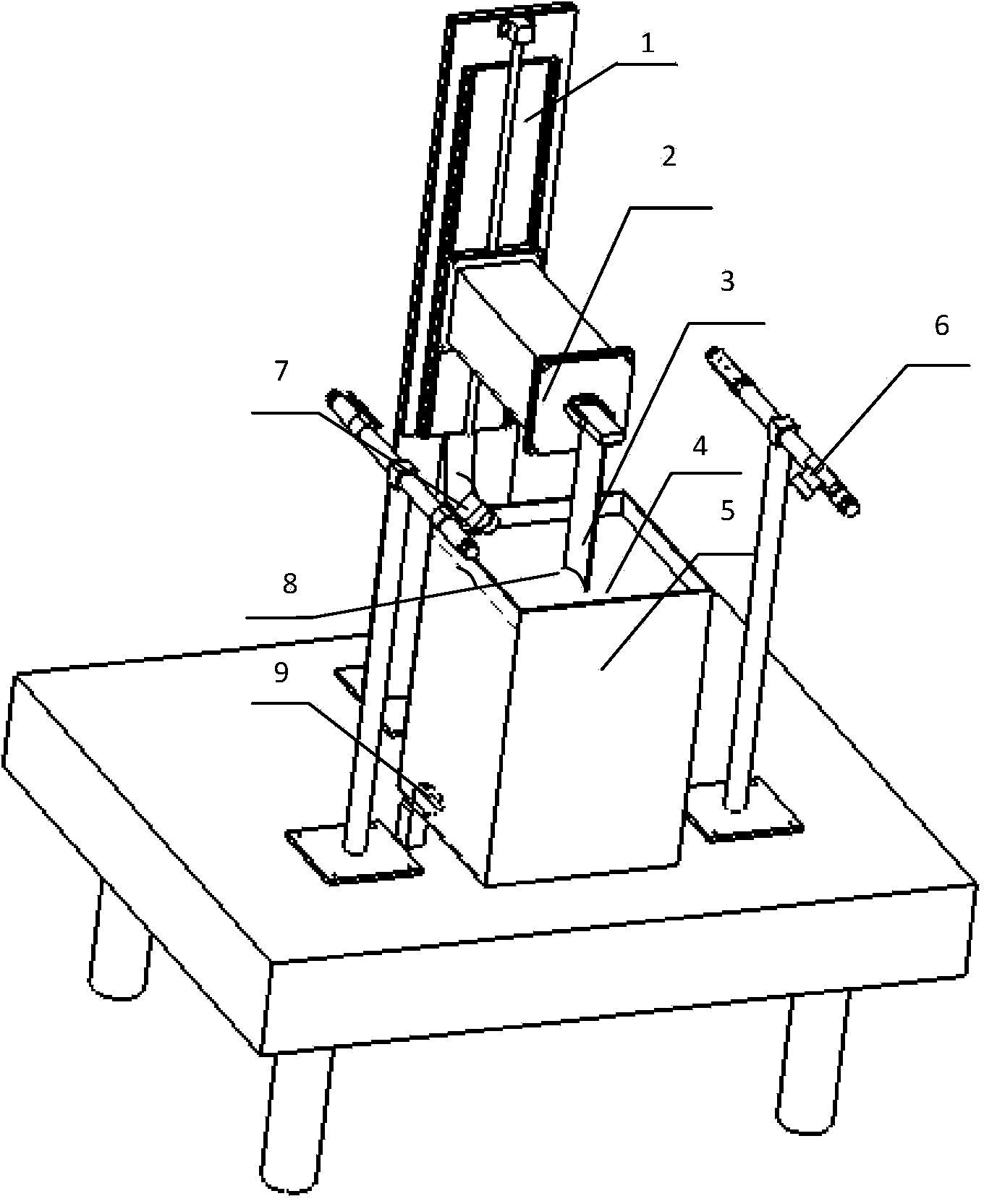

[0017] figure 1 Shown is a 3D schematic of the invented measuring device. The device mainly includes a measuring liquid 4, a liquid container 5, a clamping device 2, a displacement platform 1, a first and a second machine vision measuring system 6, 7; the measuring liquid 4 is a colored liquid, and the color is a liquid Inherent in itself, or generated by adding dyes or using colored light sources 9 and other means; the container 5 is a container for loading the measuring liquid 4, and its shape is not limited to figure 1 The shape shown; the clamping device 2 is used to clamp the measured object 3, and the base of the clamping device 2 is connected with the stage of the displacement platform 1; the displacement platform 1 is used to control the movement of the measured object, thereby Realize the full-field measurement of the three-dimensional shape of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com