Method for measuring contents of tribasic lead sulfate (3BS) and tetrabasic lead sulfate (4BS) in curing product by X-ray diffraction (XRD) external standard method

A solidified product, X-ray technology, applied in the field of detection, to achieve the effect of accurate and effective detection method, accurate quantitative analysis, and simple qualitative analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Zhengban paste: 1000kg of lead powder and 86kg of sulfuric acid, wherein the oxidation degree of lead powder is 75%, and the mass fraction of sulfuric acid is 50%.

[0025] After curing, the main components of the lead paste are PbO, 3BS (3PbO·PbSO 4 ·H 2 O) and 4BS (4PbO PbSO 4 ), moisture and free lead content are very small and negligible.

[0026] Assuming that the cured product does not generate 4BS, the components of the lead paste are PbO and 3BS, and the 3BS content after curing is 40.9%.

[0027] Assuming that the cured product does not generate 3BS, the composition of the lead paste is PbO and 4BS, and the content of 4BS after curing is 49.7%. In the actual curing process, the cured product is usually PbO, 3BS or PbO, 3BS, 4BS, so the cured product contains 3BS and 4BS. The total content of 4BS is between 40.9% and 49.7%, and the content of PbO is between 50.3% and 59.1%.

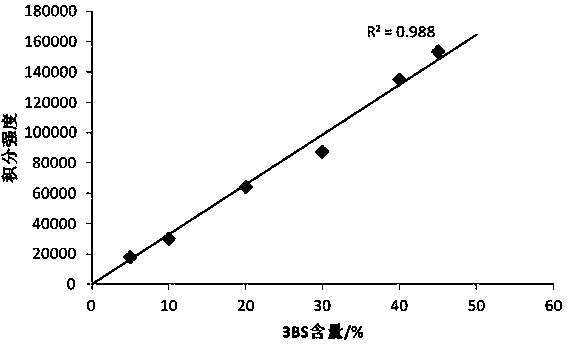

[0028] Drawing of the standard curve: In order to make the scope of the standard cu...

Embodiment 2

[0031] Zhengban paste: 1000kg of lead powder and 86kg of sulfuric acid, wherein the oxidation degree of lead powder is 75%, and the mass fraction of sulfuric acid is 50%.

[0032] After curing, the main components of the lead paste are PbO, 3BS (3PbO·PbSO 4 ·H 2 O) and 4BS (4PbO PbSO 4 ), moisture and free lead content are very small and negligible.

[0033] Assuming that the cured product does not generate 4BS, the components of the lead paste are PbO and 3BS, and the 3BS content after curing is 40.9%.

[0034] Assuming that the cured product does not generate 3BS, the composition of the lead paste is PbO and 4BS, and the content of 4BS after curing is 49.7%. In the actual curing process, the cured product is usually PbO, 3BS or PbO, 3BS, 4BS, so the cured product contains 3BS and 4BS. The total content of 4BS is between 40.9% and 49.7%, and the content of PbO is between 50.3% and 59.1%.

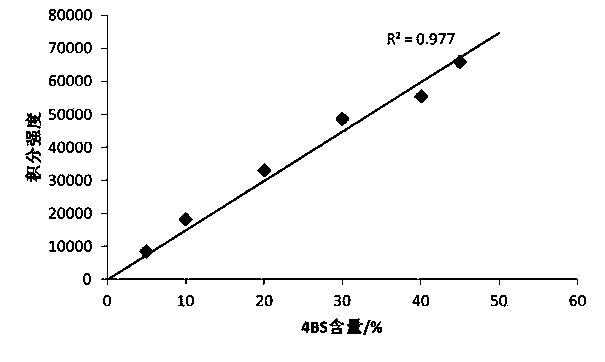

[0035] Drawing of the standard curve: In order to make the scope of the standard cu...

Embodiment 3

[0038] Zhengban paste: 1000kg of lead powder and 86kg of sulfuric acid, wherein the oxidation degree of lead powder is 75%, and the mass fraction of sulfuric acid is 50%.

[0039] After curing, the main components of the lead paste are PbO, 3BS (3PbO·PbSO 4 ·H 2 O) and 4BS (4PbO PbSO 4 ), moisture and free lead content are very small and negligible.

[0040] Assuming that the cured product does not generate 4BS, the components of the lead paste are PbO and 3BS, and the 3BS content after curing is 40.9%.

[0041] Assuming that the cured product does not generate 3BS, the composition of the lead paste is PbO and 4BS, and the content of 4BS after curing is 49.7%. In the actual curing process, the cured product is usually PbO, 3BS or PbO, 3BS, 4BS, so the cured product contains 3BS and 4BS. The total content of 4BS is between 40.9% and 49.7%, and the content of PbO is between 50.3% and 59.1%.

[0042] Drawing of the standard curve: In order to make the scope of the standard cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com