Method for qualitatively measuring nonionic surfactants of compounded system

A non-ionic surface and surfactant technology, which is applied in the field of qualitative determination of non-ionic surfactants in compound systems, can solve the problem of spending a lot of time on exploration, and achieve the effect of improving the efficiency of qualitative analysis and the convenience of qualitative methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

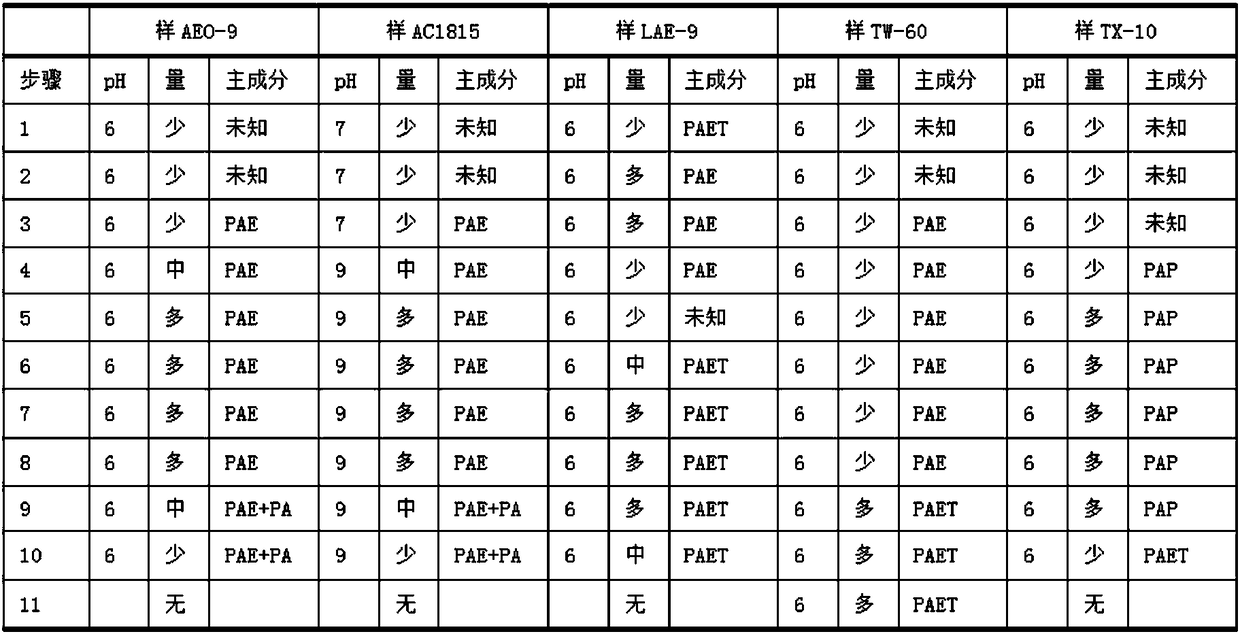

[0050] The analyst was informed that it may contain 1-5 of the above five surfactants. According to the above separation and test conditions, the data of each eluate in Example 1 are shown in Table 4. Compared with Table 3, it can be seen that: ①The pH value of each eluate in Example 1 is not greater than 6, so it does not contain AC1815; ②There is no eluate in step 11 in Table 4, indicating that Example 1 does not contain TW-60 ; 3. Step 2 in Table 4 washes out PAE, indicating that Example 1 contains LAE-9; 4. Table 4 steps 5-9 all wash out the PAP component, indicating that Example 1 contains TX-10; Illustrate, contain AEO-9 in the embodiment 1. Comparing the data of other steps in Table 4 with Table 3, it is finally concluded that Example 1 contains three surfactants: TX-10, LAE-9 and AEO-9.

Embodiment 2

[0052] The analyst was informed that it may contain 1-5 of the above-mentioned 5 kinds of surfactants. According to the above separation and test conditions, the data of each eluate in Example 2 were obtained, as shown in Table 4. Compared with Table 3, it can be seen that: ①The eluate of step 2 in Table 4 contains PAE, indicating that Example 2 contains LAE; ②The pH values of steps 4-9 in Table 4 are all greater than 6, indicating that the example contains AC1815; ③ The eluate of step 11 in Table 4 contains PAET, indicating that Example 2 contains TW-60; ④ All of the eluates of Step 5-9 in Table 4 contain PAP, indicating that Example 2 contains TX-10; ⑤ In Table 4 The eluate in step 5 contains PAE and the amount is large but the pH value is only 7, indicating that Example 2 also contains AEO-9. Combined with the data of other steps in Table 4, it is finally concluded that: Example 2 contains TX-10, LAE-9, AEO-9, AC1815, TW-60 five surfactants.

[0053] The present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com