Optimal design method for internal structure of machine tool body

A technology for optimizing design and internal structure, applied in computing, special data processing applications, instruments, etc., can solve problems such as time-consuming and increase the labor intensity of designers, and achieve the effects of saving time, optimizing target coordination, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The present invention is described by taking the YK series CNC worm gear grinding machine body of a domestic manufacturer as an example, wherein the overall size of the bed is 2500×1250×565mm, the three-dimensional software adopts Pro / e, the topology optimization software adopts Hyperworks, and the finite element software Using Ansys, auxiliary software matlab.

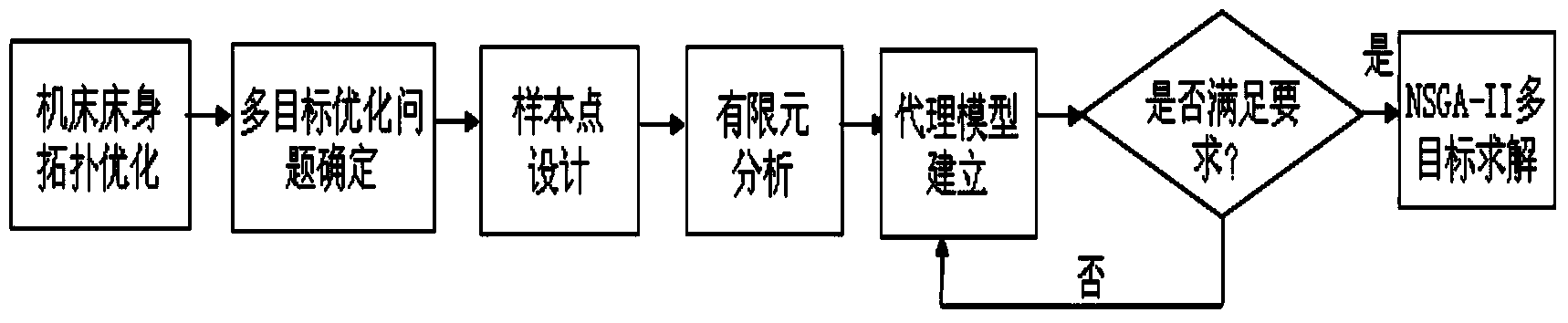

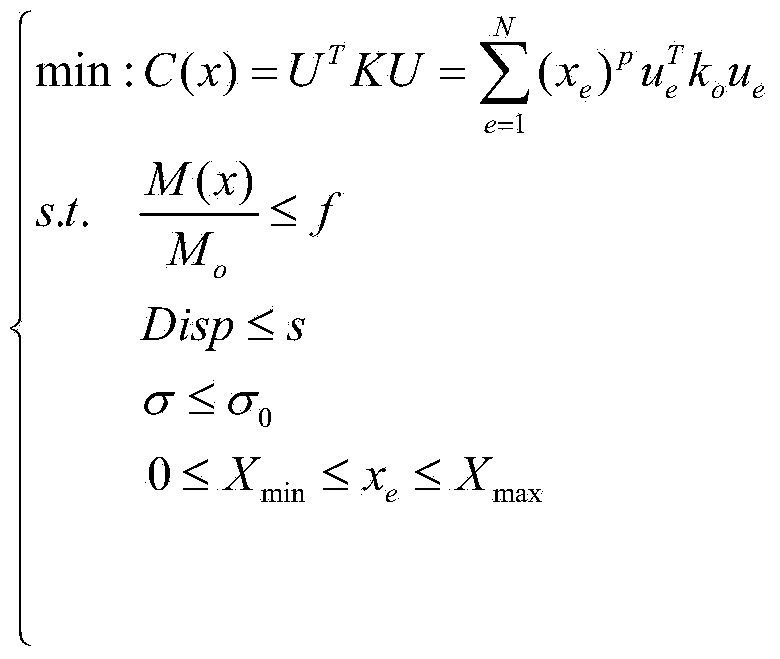

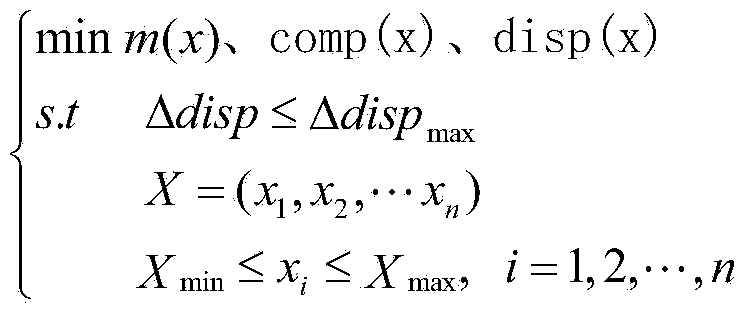

[0047] The topology optimization step of the internal structure of the machine bed includes the following steps:

[0048] a1) Establish the 3D CAD model of the machine bed in the Pro / e software based on the existing bed model or the 2D engineering drawing of the machine bed; use the seamless interface between the Pro / e software and the topology optimization software Hyperworks The 3D CAD model of the machine bed is imported into Hyperworks; the 3D CAD model of the machine bed is divided into a topology optimization area and a non-topology optimization area, and the area outside the bed that has an assembly rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com