Novel flame-retardant fireproof cable

A fireproof cable, a new type of technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem of high cost, achieve the effects of low cost, not easy to short circuit, and easy to make

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

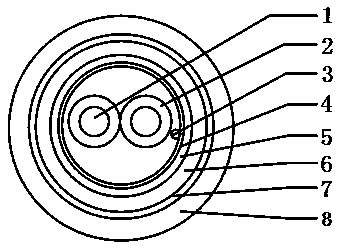

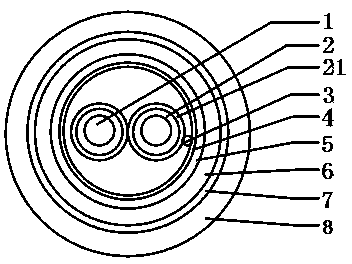

[0025] please see figure 2 , a new type of flame retardant and fireproof cable, which is composed of two insulated wires, an aluminum-plastic composite tape 4 covering the insulated wires, a braided layer 5 located outside the aluminum-plastic composite tape, and an extrusion coating on the outside of the braided layer The inner sheath 6, the armor layer 7 coated outside the inner sheath, and the outer sheath 8 coated outside the armor layer by extrusion molding; it is characterized in that each insulated wire is composed of a conductor 1, a sheath The polyethylene insulating layer 2 that covers the conductor is composed of a ceramic insulating layer 21 that is extruded and coated on the polyethylene insulating layer; there is a drain core wire 3 on the outside of the insulating wire, and the aluminum-plastic composite tape connects the drain core wire and the insulating wire Coated at the same time; two insulated wires are a pair, which are placed in parallel or twisted with...

Embodiment 2

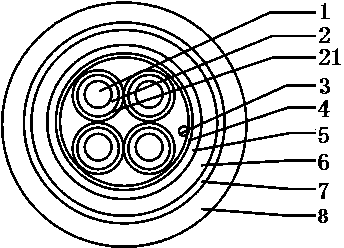

[0027] please see image 3 , a new type of flame-retardant and fire-resistant cable, which is composed of four insulated wires, an aluminum-plastic composite tape 4 covering the insulating wires, a braided layer outside the aluminum-plastic composite tape 5, and an extrusion-coated braided layer The inner sheath 6, the armor layer 7 coated outside the inner sheath, and the outer sheath 8 coated outside the armor layer by extrusion molding; it is characterized in that each insulated wire is composed of a conductor 1, a sheath The polyethylene insulating layer 2 that covers the conductor is composed of a ceramic insulating layer 21 that is extruded and coated on the polyethylene insulating layer; there is a drain core wire 3 on the outside of the insulating wire, and the aluminum-plastic composite tape connects the drain core wire and the insulating wire Covering at the same time; the four insulated wires form two pairs, and the drainage core wire is located in the outer gap for...

Embodiment 3

[0029] please see Figure 4 , a new type of flame retardant and fireproof cable, which is composed of four insulated wires, an aluminum-plastic composite tape 4 covering the insulated wires, a braided layer outside the aluminum-plastic composite tape 5, and an extrusion-coated braided layer The inner sheath 6, the armor layer 7 coated outside the inner sheath, and the outer sheath 8 coated outside the armor layer by extrusion molding; it is characterized in that each insulated wire is composed of a conductor 1, a sheath The polyethylene insulating layer 2 that covers the conductor is composed of a ceramic insulating layer 21 that is extruded and coated on the polyethylene insulating layer; there is a drain core wire 3 on the outside of the insulating wire, and the aluminum-plastic composite tape connects the drain core wire and the insulating wire Covering at the same time; the four insulated wires form two pairs, and the drainage core wire is located in the inner gap formed b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com