Lithium battery cover cap

A technology for lithium batteries and caps, applied in the direction of battery cover/end cover, battery pack parts, battery box/coating, etc., can solve the problems of small aluminum sheet deformation, efficiency reduction, scrapping, etc., to avoid direct contact, slow down The degree of stress and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

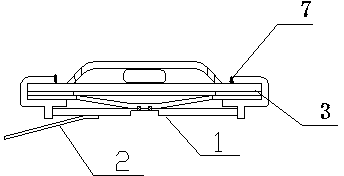

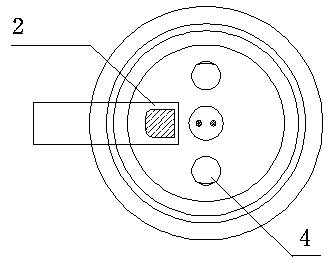

[0035] Depend on figure 1 , figure 2 and Figure 5 As shown, the non-flat top cover lithium battery safety combination cap includes a top cover, a bottom cover, and a safety valve. It is characterized in that the bottom cover 3 is improved: the aluminum sheet 1 in the bottom cover 3 is welded with tabs 2 , located in the area where the arcs corresponding to the endpoints of the two circular vent holes 4 of the aluminum sheet 1 are located.

[0036] The explosion-proof sheet on the bottom cover wraps the top cover, and the edge is sealed with an ultrasonic welding machine or a laser welding machine. The welded part 7 forms an alloy body, so that the battery cover becomes a whole. The preferred solution: the welding place 7 is two symmetrical welding spots; the welding place is an ultrasonic welding spot or a laser welding spot. It is also possible to weld the explosion-proof plate on the top cover and the bottom cover up and down to form a whole, and the welded part forms a...

Embodiment 2

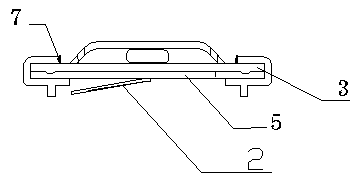

[0043] Depend on image 3 , Figure 4 and Figure 5 As shown, the flat top cover lithium battery safety combination cap includes a top cover, a bottom cover, and a safety valve. It is characterized in that the bottom cover 3 is improved: a tab 2 is welded on the flat explosion-proof plate 5 in the bottom cover 3, It is located at the center position corresponding to the arc 6 of the flat explosion-proof disc 5 .

[0044] The explosion-proof sheet on the bottom cover wraps the top cover, and the edge is sealed with an ultrasonic welding machine or a laser welding machine. The welded part 7 forms an alloy body, so that the battery cover becomes a whole. The preferred solution: the welding place 7 is two symmetrical welding spots; the welding place is an ultrasonic welding spot or a laser welding spot. It is also possible to weld the explosion-proof plate on the top cover and the bottom cover up and down to form a whole, and the welded part forms an alloy body. The preferred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com