Ink jet recording method

An inkjet recording method and technology for recording media, which are used in copying/marking methods, inks, printing, etc., can solve the problems of high manufacturing cost, high operating cost, waste generation, etc. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0472]The prepared primer P1 was filled in a UV inkjet printer Acuity LED1600 manufactured by Fujifilm Corporation. As the ink, Uvijet LL ink (ultraviolet curable ink composition, cyan, magenta, yellow, black, light cyan, light magenta, and white colors) manufactured by Fujifilm Co., Ltd. was used. Using glass (manufactured by Asahi Glass Co., Ltd., TEMPERLITE) as the recording medium, print a primer layer between the recording medium and the test image in high-resolution mode by printing separately, or print a white solid on a part of the test image image. Then, evaluation of curability, initial stage adhesiveness, and weather resistance was performed using the obtained printed matter by the following reference|standard. The results are shown in Table 2.

Embodiment 2~7 and comparative example 1~3

[0474] In Example 1, as shown in Table 2, primers P2 to P7, CP1 or CP2 were used instead of primer P1, or no primer was used, and printed matter was produced in the same manner as in Example 1 except that , curability, initial adhesiveness, and weather resistance were evaluated using the obtained printed matter. The results are shown in Table 2.

[0475]

[0476] Regarding curability, the stickiness of the surface of the printed matter based on the touch of each ink 100% concentration part and the presence or absence of transfer in the image part when the printed matter was stacked and left for 1 day (at 25° C.) were evaluated according to the following criteria.

[0477] 0: There is no stickiness at all on the surface of the printed matter, and there is no transfer.

[0478] 1: There is slight stickiness on the surface of the printed matter, but no transfer.

[0479] 2: There is stickiness on the surface of the printed matter, and transfer occurs slightly.

[0480] 3: Th...

Embodiment 8~14 and comparative example 4~6

[0496] In Examples 1-7 and Comparative Examples 1-3, except having used the LL ink which added the ultraviolet absorber instead of LL ink, it carried out similarly to Examples 1-7 and Comparative Examples 1-3, and produced the printed matter. Then, curability, initial stage adhesiveness, temporal adhesiveness, and weather resistance were evaluated using the obtained printed matter. The results are shown in Table 3.

[0497] table 3

[0498]

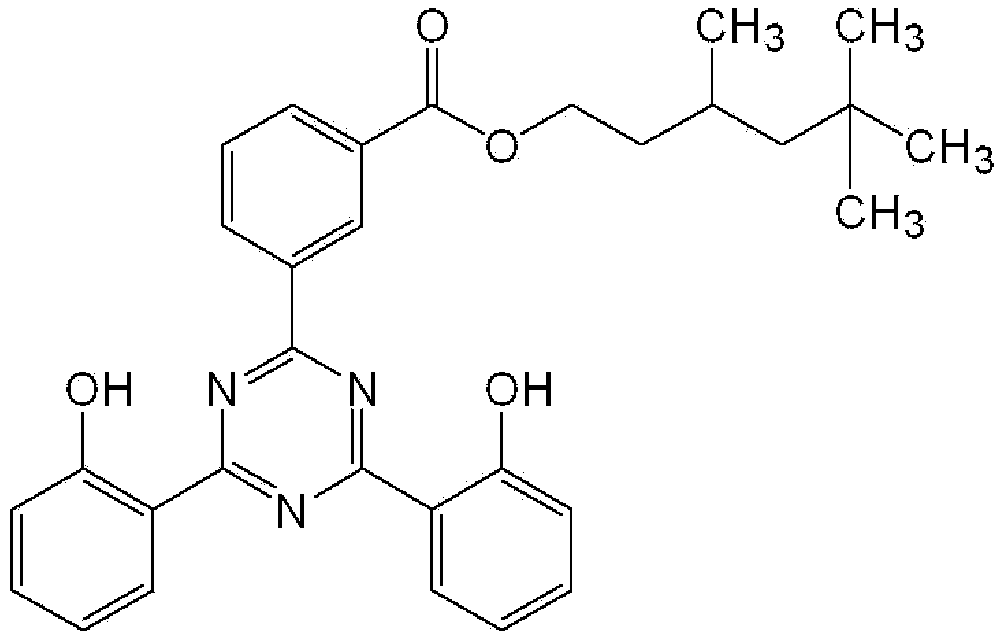

[0499] (Preparation of primers P8~P11 and CP3)

[0500] The following components were stirred at 2,500 rpm for 15 minutes using a stirrer (L4R manufactured by Silverson Corporation). Thereafter, the resulting mixture was filtered using a cartridge filter (product name Profile IIAB01A01014J) manufactured by Nippon Pall Corporation to obtain primers P8 to P11 and CP3, respectively. In addition, the addition amount of TATZ-1 is shown in Table 4.

[0501]

[0502] 2-Methoxy-1-methylethyl acetate: (34.0-X) parts

[0503] Cyclohexanon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com